Plate heat exchanger pressing plate and manufacturing method thereof

A plate heat exchanger and compression plate technology, applied in the direction of lamination elements, heat exchange equipment, lighting and heating equipment, etc., can solve the problems of waste of raw materials, low production efficiency, backward technology, etc., and achieve mechanization and weight reduction. , the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

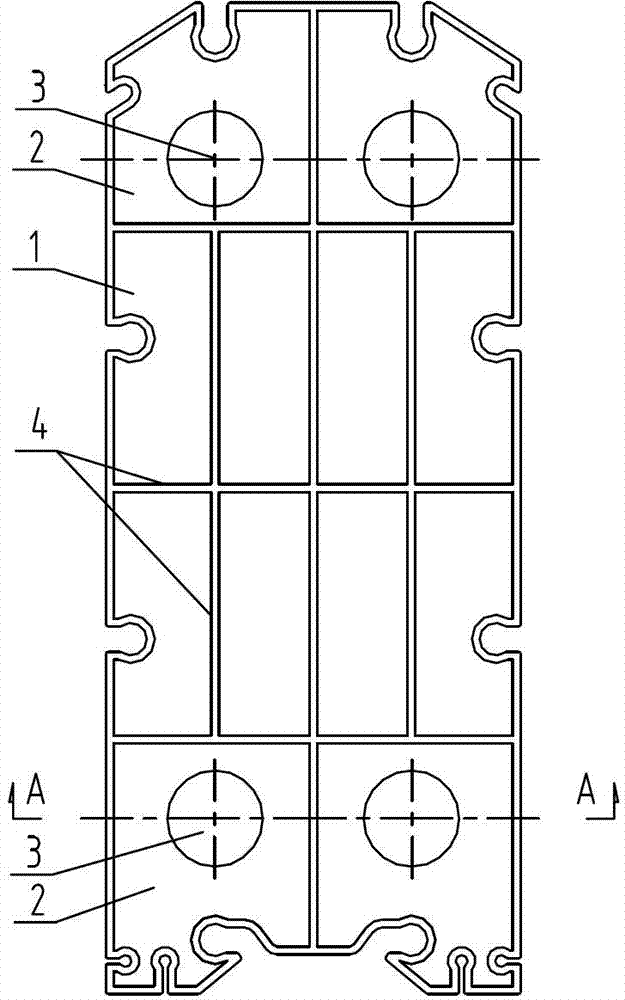

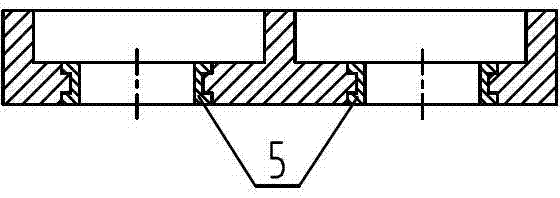

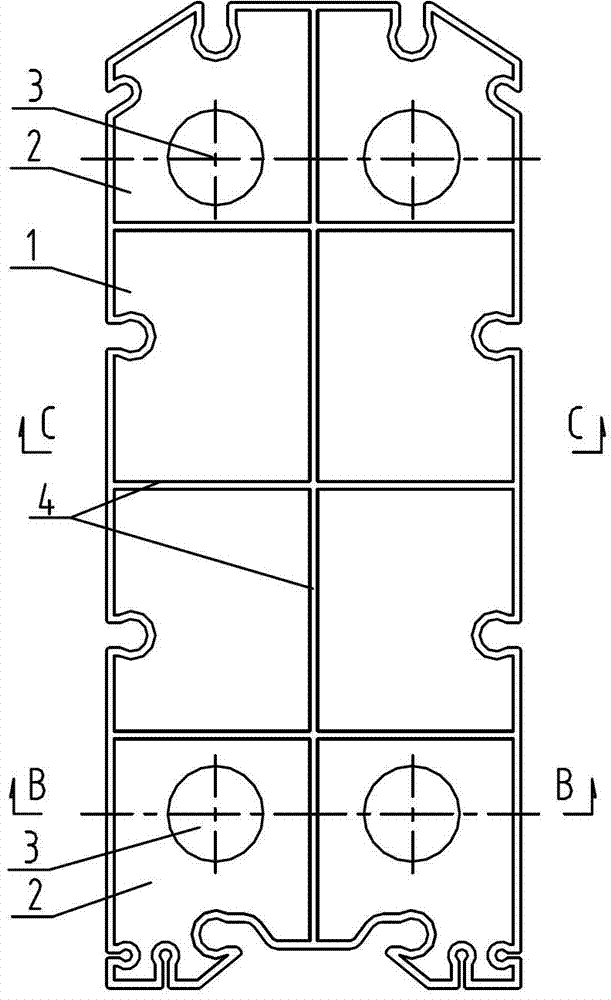

[0042] See figure 1 , Picture 1-1 , which is a structural schematic diagram of Embodiment 1 of the compression plate of a plate heat exchanger according to the present invention, including a heat exchange area 1 and channel areas 2 at both ends, the channel area 2 is provided with corner holes 3, and the heat exchange area 1 is provided with increased strength The rib grid 4 and the corner hole 3 are pre-embedded with an annular steel sleeve 5; the surface of the passage area 2 at both ends is concave, and the lower surface is a plane. The surface of the heat exchange zone 1 is made concave, the lower surface is plane, and the rib lattice 4 is arranged on the concave surface. Rib grid 4 constitutes a rectangular grid.

[0043] The compression plate in the embodiment is made of resin material, and its specific operation steps are as follows:

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com