Device for non-contact measurement of junction temperature of white LED by use of peak wavelength displacement method

A non-contact measurement, peak wavelength technology, applied in the direction of measuring devices, measuring heat, thermometers, etc., can solve the problems of test result error, increase test cost, etc., achieve the effect of reducing error, improving accurate value, and wide application fields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

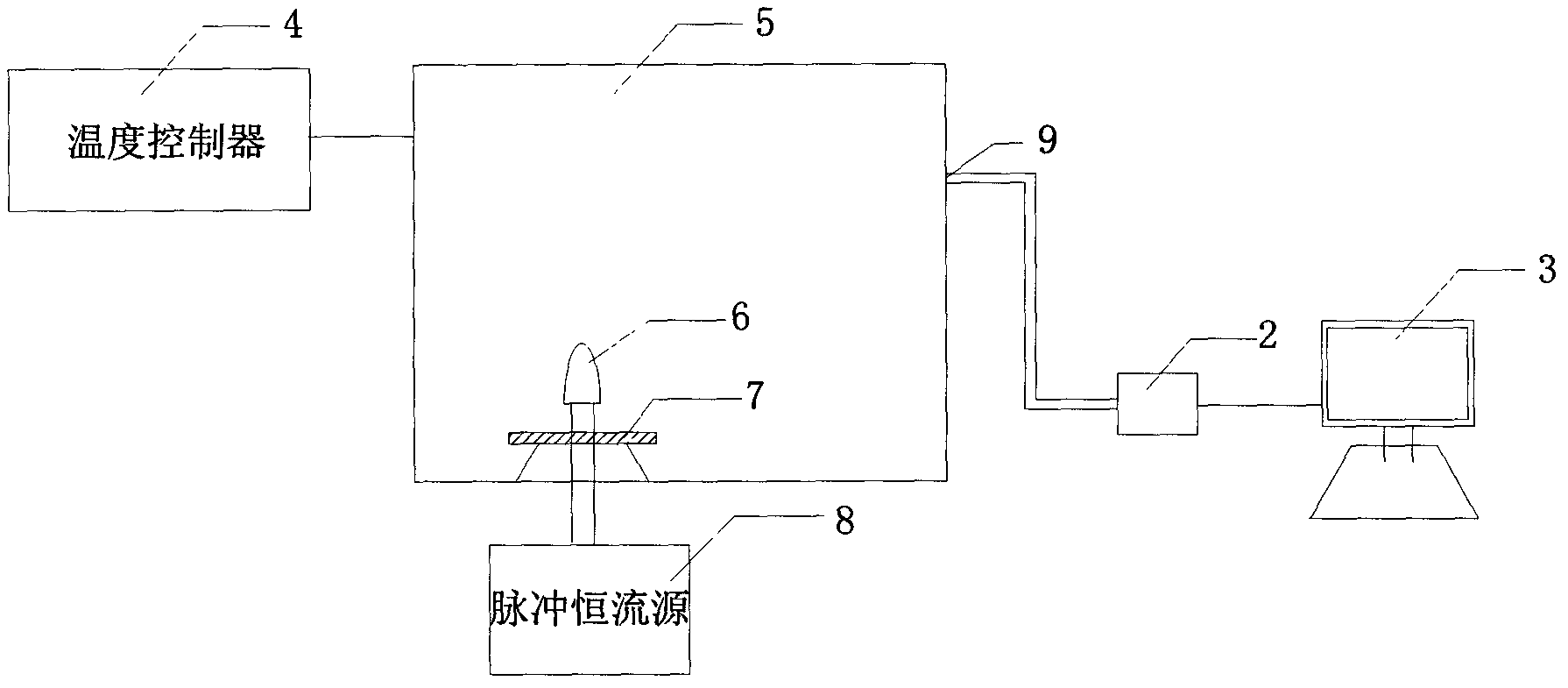

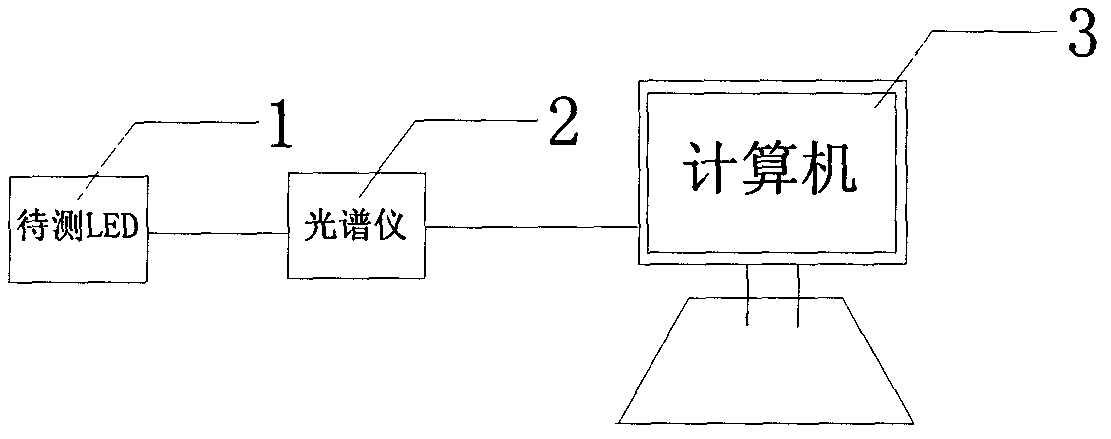

[0024] The invention uses a peak wavelength shifting method to design a fast non-contact measuring white light LED junction temperature device. The device includes the design of a spectrometer for measuring the wavelength shift of blue light, the calibration of the peak wavelength-junction temperature coefficient K of commonly used white light LEDs, and the measurement of the junction temperature of LEDs under normal working conditions.

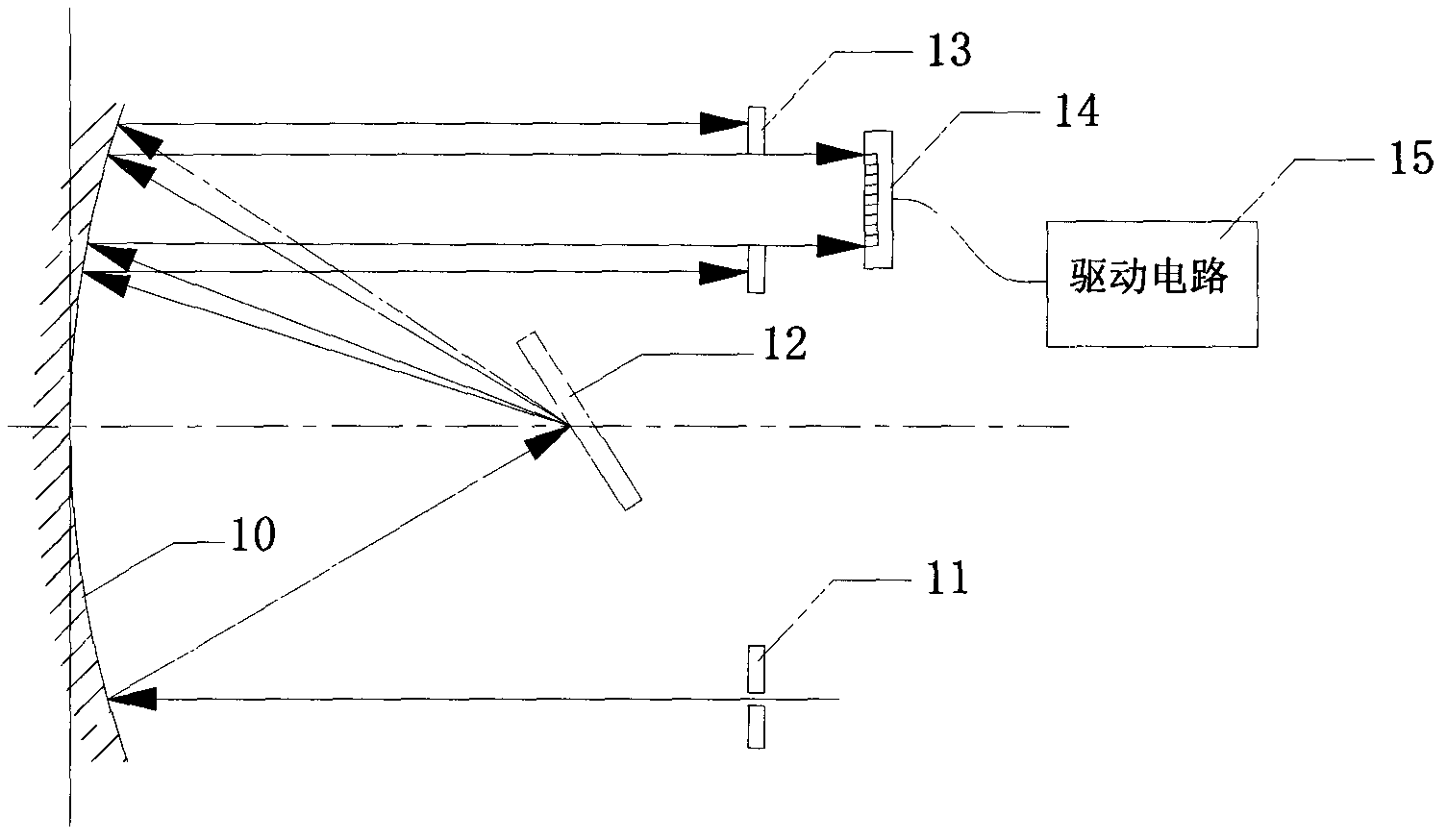

[0025] The spectrometer for measuring the blue light wavelength shift of the present invention controls the diffracted light by determining the parameters and angles of the plane grating, so that the reflected diffracted light can pass through the exit slit only when the wavelength is within the range of 440nm-470nm. In this embodiment, a linear array CCD with 2048 pixel elements is selected, and the height of the photosensitive surface of the CCD is equal to the width of the exit slit. The optical signal obtained by the detector is converted...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com