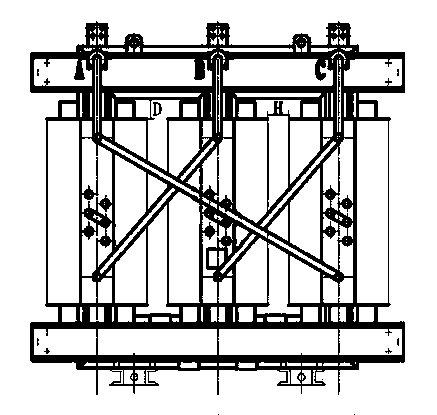

Dry type transformer and production process of high-voltage coil thereof

A technology of dry-type transformers and high-voltage coils, applied in the direction of transformer/inductor coil/winding/connection, coil manufacturing, etc., to achieve good chemical corrosion resistance, ensure technical performance parameters, and reduce noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] The process steps of using NMN silicone rubber composite material to produce high-voltage coil of dry-type transformer:

[0050] 1. Clean the inner mold, apply mold release oil, and paste mold release paper;

[0051] 2. Install the silicone rubber composite material, take the NMN silicone rubber composite sheet with a thickness of 1.5mm, and contact the silicone rubber surface of the NMN silicone rubber composite sheet with the release paper surface;

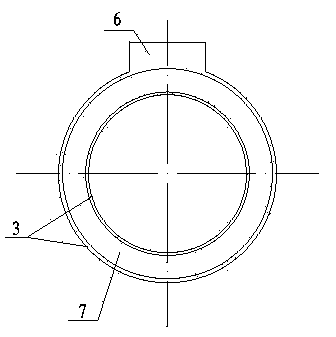

[0052] 3. Install a 1mm grid 3 close to the NMN silicone rubber composite sheet, wind the electromagnetic coil 7 of the high voltage coil, and install a 1mm grid 3 close to the electromagnetic coil 7 of the high voltage coil;

[0053] 4. Install the silicone rubber composite material, take the NMN silicone rubber composite sheet with a thickness of 1.5mm, and contact the NMN surface of the NMN silicone rubber composite sheet with the 3 surfaces of the 1mm grid;

[0054] 5. Install outer mold, epoxy resin pouring, curing, coil polis...

Embodiment 2

[0056] The process steps of using MN silicone rubber composite material to produce dry-type transformer high voltage coil:

[0057] 1. Clean the inner mold, apply mold release oil, and paste mold release paper;

[0058] 2. Install the silicone rubber composite material, take the MN silicone rubber composite sheet with a thickness of 2mm, and contact the silicone rubber surface of the MN silicone rubber composite sheet with the release paper surface;

[0059] 3. Install a 1mm grid 3 close to the MN silicon rubber composite sheet, wind the electromagnetic coil 7 of the high voltage coil, and install a 1mm grid 3 close to the electromagnetic coil of the high voltage coil;

[0060] 4. Install the silicone rubber composite material, take the MN silicone rubber composite sheet with a thickness of 2mm, and contact the MN surface of the MN silicone rubber composite sheet with the 3 surfaces of the 1mm grid;

[0061] 5. Install outer mold, epoxy resin pouring, curing, coil polishing and finishin...

Embodiment 3

[0063] The process steps of using DMD silicone rubber composite material to produce dry-type transformer high voltage coil:

[0064] 1. Clean the inner mold, apply mold release oil, and paste mold release paper;

[0065] 2. Install the silicone rubber composite material, take a DMD silicone rubber composite sheet with a thickness of 1.5 mm, and contact the silicone rubber surface of the DMD silicone rubber composite sheet with the release paper surface;

[0066] 3. Install a 1mm grid 3 close to the DMD silicon rubber composite sheet, wind the electromagnetic coil 7 of the high-voltage coil, and install the 1mm grid 3 of the electromagnetic coil 7 close to the high-voltage coil;

[0067] 4. Install the silicone rubber composite material, take the DMD silicone rubber composite sheet with a thickness of 1.5mm, and contact the DMD surface of the DMD silicone rubber composite sheet with the 3 surfaces of the 1mm grid;

[0068] 5. Install outer mold, epoxy resin pouring, curing, coil polishin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com