Integrated type miniaturized round proximity switch

A proximity switch and integrated technology, which is applied in the field of miniaturized circular proximity switches, can solve problems such as the influence of measurement accuracy, the unsatisfactory structure of the separation of the sensor and the conversion circuit, and the easy interference of the inductance signal, so as to reduce the weight of the product and improve the quality of the product. The effect of product testing accuracy and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but the present invention is not limited to the scope of the described embodiments.

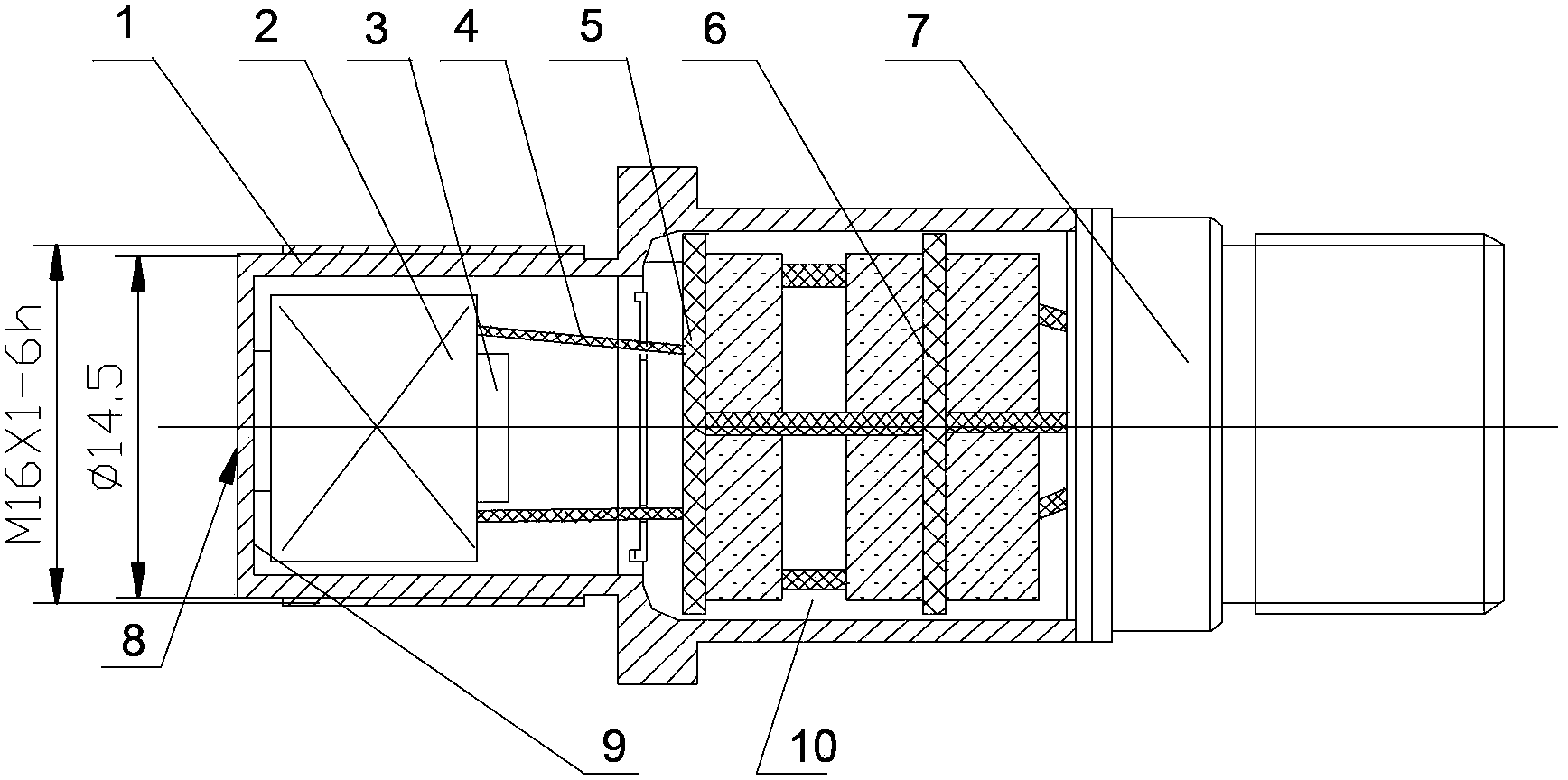

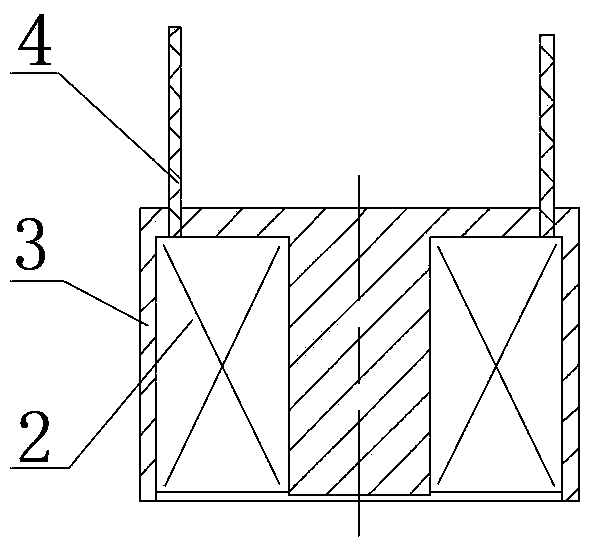

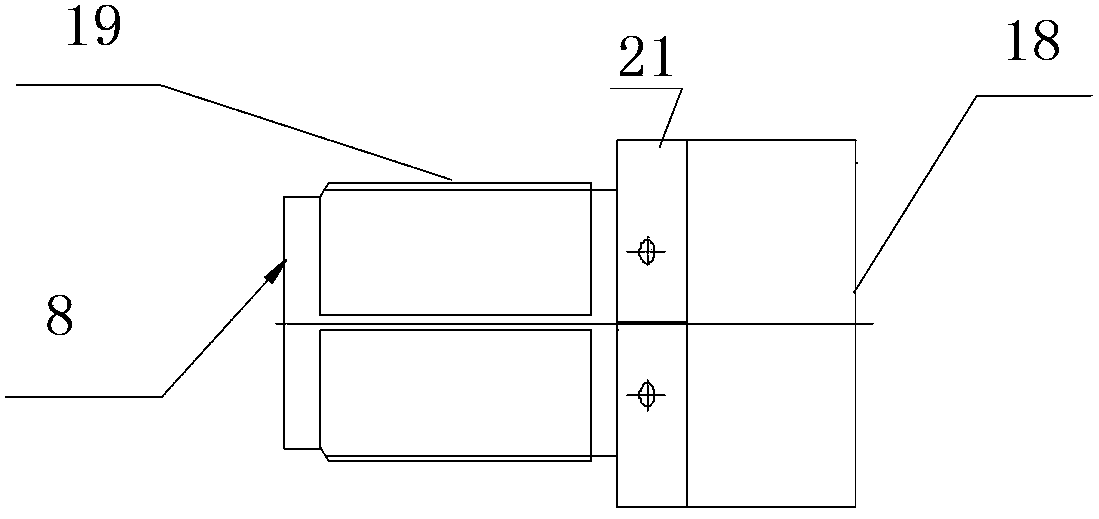

[0018] exist Figure 1 to Figure 5 In the described embodiment of the miniaturized circular proximity switch, the miniaturized circular proximity switch has a working section with an outer diameter of 14.5mm and a length of 3mm, extending to the right to the carrier mechanical interface to install the thread 19, and the end of the thread is the side length S = 21mm regular hexagonal flange. The other side of the flange is a thin-walled cylinder with a diameter of about Φ21. The metal casing opening 18 is vacuum-tightly welded to the outer surface of the corresponding part of the socket 7 . The stabilized power supply board 6 is equipped with a power supply module and required peripheral devices, and the receiving circuit board 5 is equipped with a micro-inductance rece...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com