Isobutene preparation method

A technology of isobutene and isobutane, applied in chemical instruments and methods, chemical recovery, hydrocarbons, etc., can solve the problems of conversion rate, low selectivity, difficulty in large-scale process, easy deactivation of catalysts, etc., and achieve the reaction process. Easy, avoid frequent regeneration, easy to scale effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

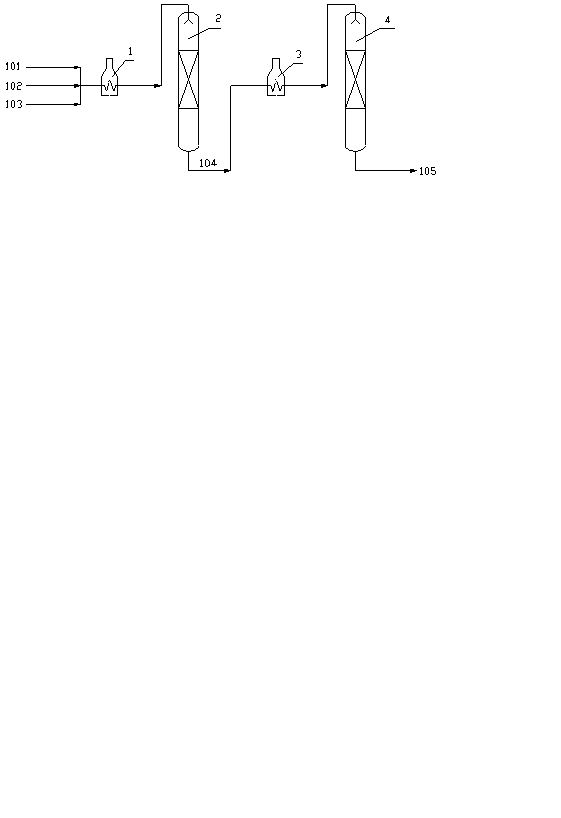

[0027] A 100,000-ton / year isobutane dehydrogenation to isobutene plant (8,000 hours of operation per year), part of the isobutane dehydrogenation reaction to isobutene figure 1 Process technology. An alumina catalyst containing 0.77% Pt based on the catalyst weight percentage was used. The raw material isobutane, circulating hydrogen and steam are mixed and passed into the adiabatic fixed bed dehydrogenation reactor. The molar ratio of isobutane to hydrogen is 2.5, the molar ratio of steam to isobutane is 4, and the inlet temperature of the first reactor is 618. ℃, the second reactor inlet temperature is 628℃, the first reaction outlet temperature is 520℃, the second reactor outlet temperature is 563℃, the reaction pressure is 0.1MPa, the isobutane weight space velocity is 4.0 hours -1 Under the above conditions, isobutene is produced in a two-stage two-stage fixed-bed reactor with interstage heat exchange. A heating furnace is arranged between the reactors to heat the outlet ...

Embodiment 2

[0031] A 100,000-ton / year isobutane dehydrogenation to isobutene plant (8,000 hours of operation per year), part of the isobutane dehydrogenation reaction to isobutene figure 1 Process technology. The molar ratio of isobutane to hydrogen is 2.5, the molar ratio of steam to isobutane is 1.2, the inlet temperature of the first reactor is 645°C, the inlet temperature of the second reactor is 650°C, and the outlet temperature of the first reaction is 520°C. The outlet temperature of the reactor was 563°C, and the other conditions were the same as in Example 1.

[0032] The single-pass conversion rate of the reaction is 50%, the selectivity of isobutylene is 89%, the reaction regeneration cycle is 84 hours, and the regeneration time is 8 hours.

[0033]

Embodiment 3

[0035] A 100,000-ton / year isobutane dehydrogenation to isobutene plant (8,000 hours of operation per year), part of the isobutane dehydrogenation reaction to isobutene figure 1 Process technology. The molar ratio of isobutane to hydrogen is 2.5, the molar ratio of steam to isobutane is 5, the inlet temperature of the first reactor is 613°C, the inlet temperature of the second reactor is 623°C, and the outlet temperature of the first reaction is 520°C. The outlet temperature of the reactor was 562°C, and the other conditions were the same as in Example 1.

[0036] The single-pass conversion rate of the reaction is 56%, the isobutylene selectivity is 92%, the reaction regeneration cycle is 120 hours, and the regeneration time is 8 hours.

[0037]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com