Frosted PET (polyethylene glycol terephthalate) packaging bottle additive and application thereof

A technology for additives and packaging bottles, which is applied in the field of frosted PET packaging bottle additives, can solve the problems affecting PET characteristics, etc., achieve the effect of improving taste, solving the defects of transparency and singleness, and maintaining smooth hand feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

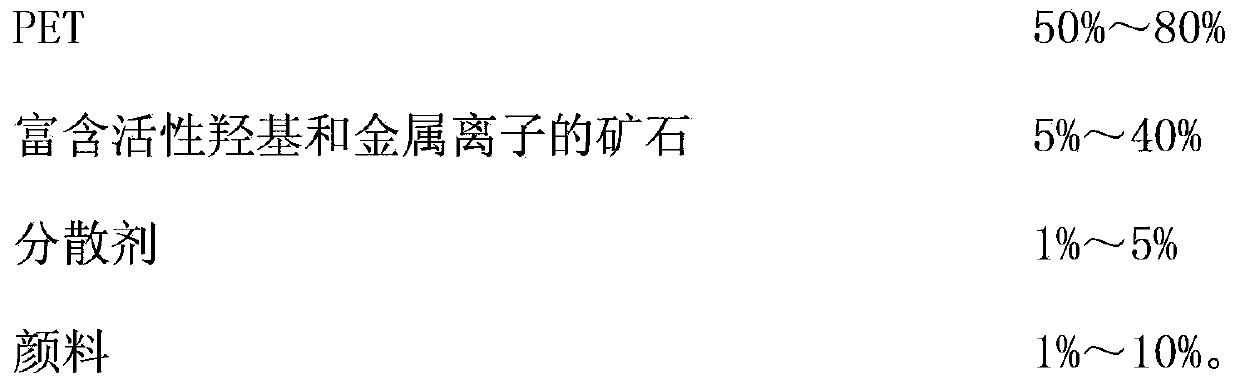

[0023] The preparation method of the present invention is the same as that of general plastic masterbatches. The raw materials are weighed according to the proportion and mixed for 3-5 minutes, and then extruded and granulated into masterbatches with a twin-screw extruder according to conventional process parameters.

[0024] The method for preparing finished product bottle when the present invention is applied is as follows:

[0025] The prepared matte PET packaging bottle additive masterbatch and PET raw materials are mixed at a weight ratio of 1:100 to 5:100, and then blown by the set blowing machine process temperature for injection, stretching, blowing and other processes.

[0026] Polyester plastics contain metal ions, which will increase the cold crystallization temperature and cold crystallization speed of polyester plastics.

[0027] Firstly, the effect of ores rich in active hydroxyl groups and metal ions on PET crystallization is verified through verification exampl...

Embodiment 1

[0045] PET50%, illite 40%, polyethylene wax 5%, pigment 5%.

Embodiment 2

[0047] PET60%, illite 30%, microcrystalline wax 1%, pigment 9%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com