System and method for water spray injection type pulse steam electric power generation

A power generation system and injection technology, applied in steam engine installations, solar thermal power generation, machines/engines, etc., can solve the problems of unguaranteed energy conversion efficiency from thermal energy to steam potential energy, low accuracy, high energy consumption and cost, Achieve the effect of efficient and feasible thermoelectric conversion, power generation cost and environmental protection of power generation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

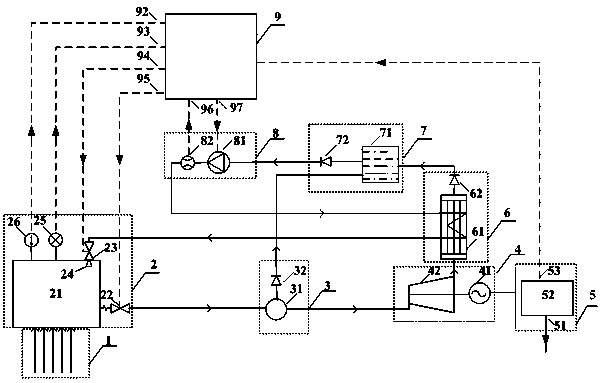

[0040] Such as figure 1 As shown, a water injection injection pulse steam power generation system includes a thermal energy input unit 1, a steam boiler 2, a gas-liquid separation unit 3, a power generation unit 4, a cooling recovery unit 6, a recovery water tank unit 7, and a forced quantitative water spray unit 8 and the main control unit 9; the thermal energy input provided by the thermal energy input unit 1 includes but not limited to high-quality thermal energy such as photothermal energy, electric thermal energy, chemical thermal energy and combustion thermal energy.

[0041]The steam boiler 2 includes a steam generator 21, a steam release valve 22, a water injection valve 23, a pressure sensor 25 and a temperature sensor 26, wherein ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com