Hydraulic generating set for deceleration strip

A power generation device and deceleration belt technology, which is applied in the direction of machines/engines, mechanical equipment, mechanisms that generate mechanical power, etc., can solve the problems of high mechanical friction, difficult repair, short life, etc., to slow down the instantaneous impact and reduce energy loss , the effect of prolonged action time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention is described in more detail below in conjunction with accompanying drawing example:

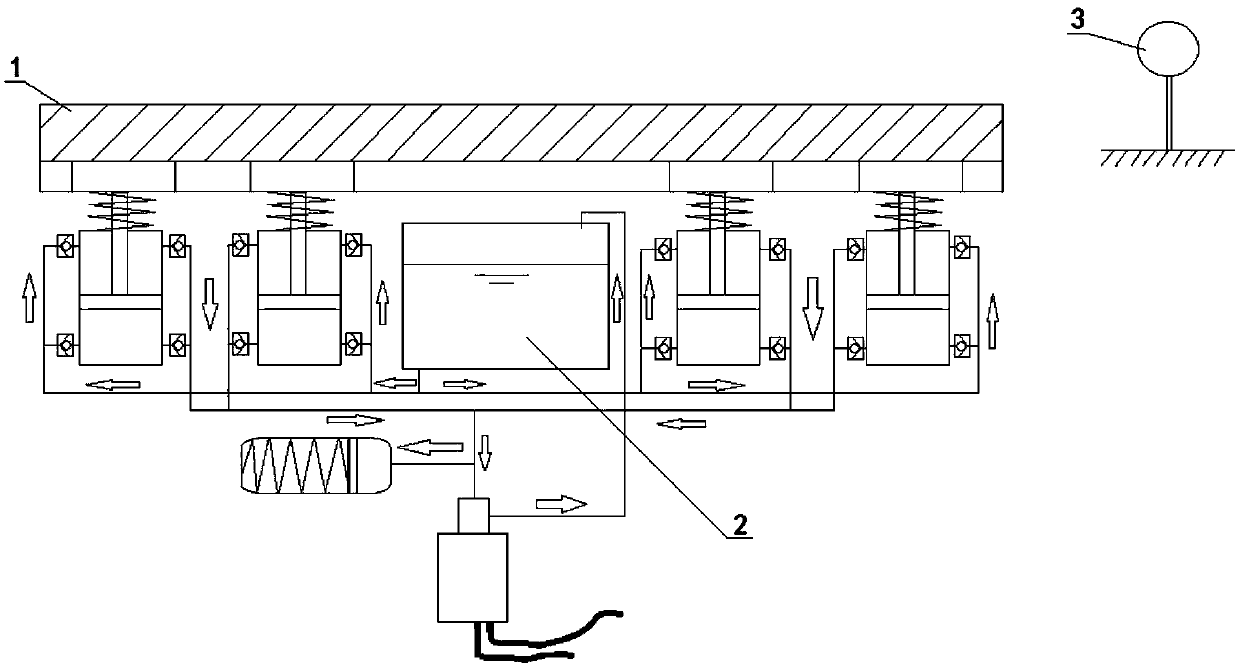

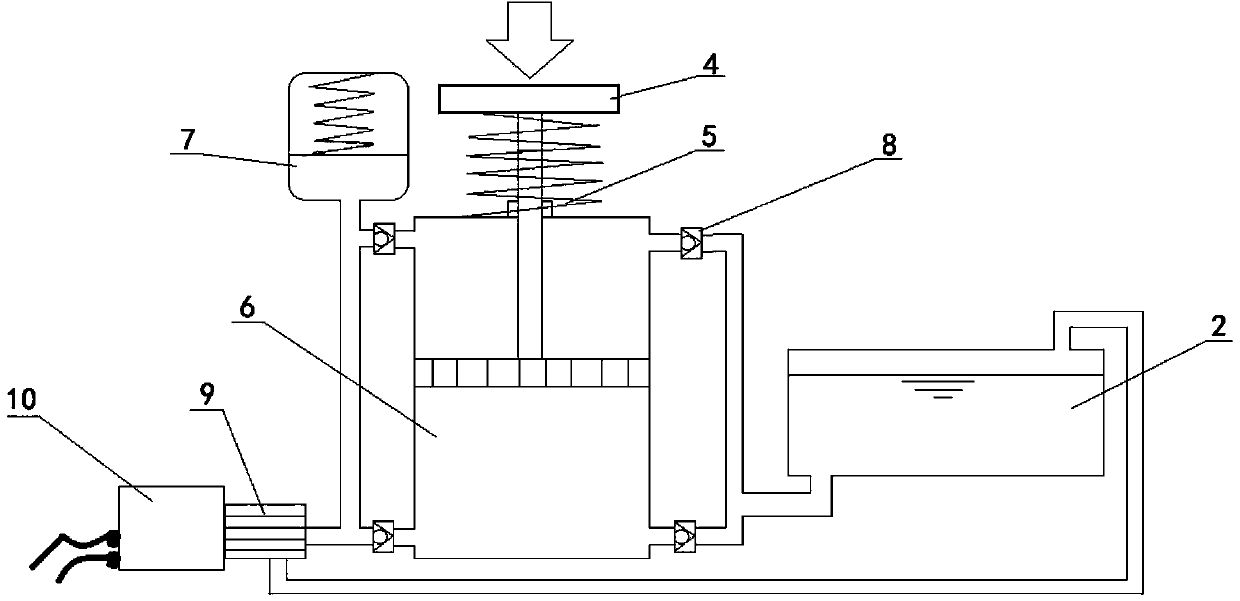

[0020] combine Figure 1~2 , the speed bump 1 of the present invention, the generator 10 and the fuel tank 2 are fixedly connected with a number of positioning round blocks 4 under the speed bump 1, and each positioning round block 4 is connected with a piston rod, and the piston rod is connected with the double-acting hydraulic cylinder 6 The pistons inside are connected, and a return spring 5 is arranged between the positioning round block 4 and the double-acting hydraulic cylinder 6; the double-acting hydraulic cylinder 6 is respectively connected with the hydraulic motor 9 and the oil tank 2 through the confluence pipeline, and the hydraulic motor 9 is connected with the generator 10, the oil return port of the hydraulic motor 9 is connected to the oil tank 2; a check valve 8 is provided at the junction of the confluence pipeline and the double-acting hydrauli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com