Split shield tunneling machine hydraulic pushing control valve set convenient to assemble and control method thereof

A technology of propulsion control and shield machine, which is applied in earth-moving drilling, mechanical equipment, servo motor components, etc., can solve the problems of difficult installation and maintenance of hydraulic propulsion system, save installation space, facilitate fault maintenance, and reduce length.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

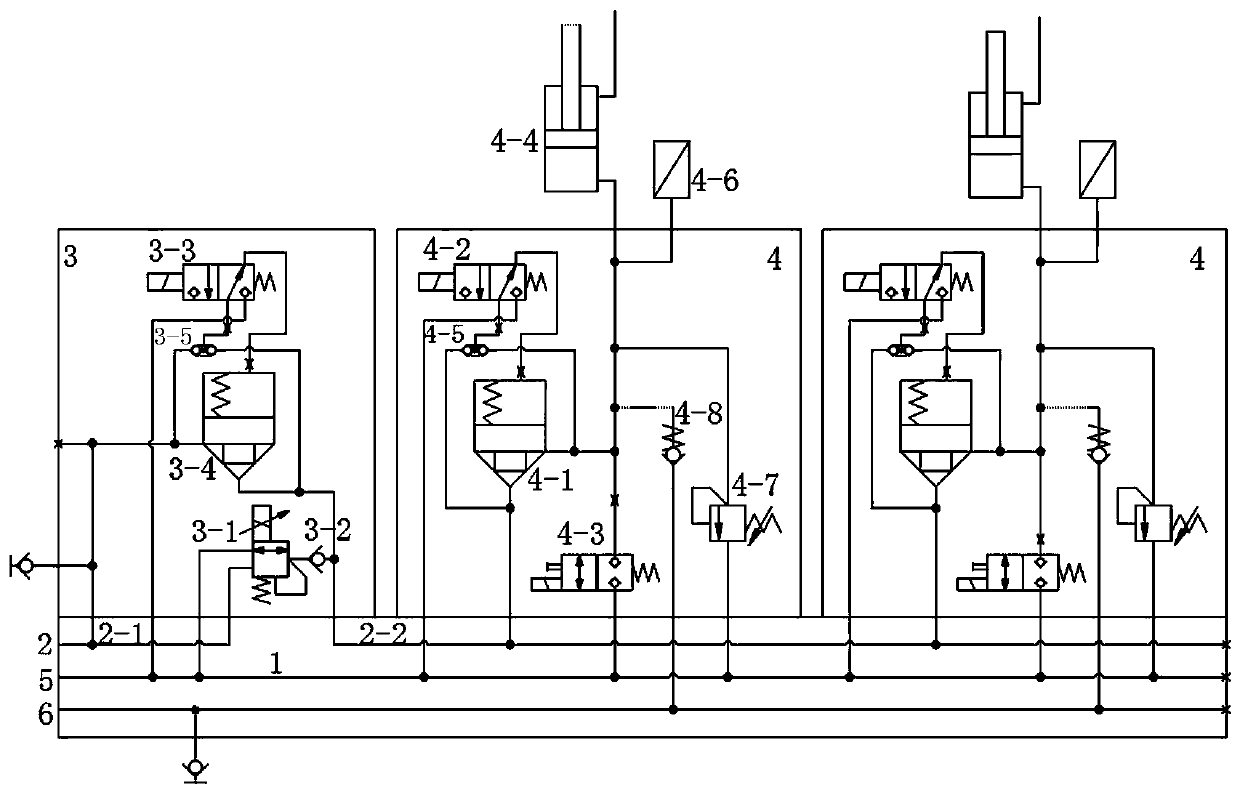

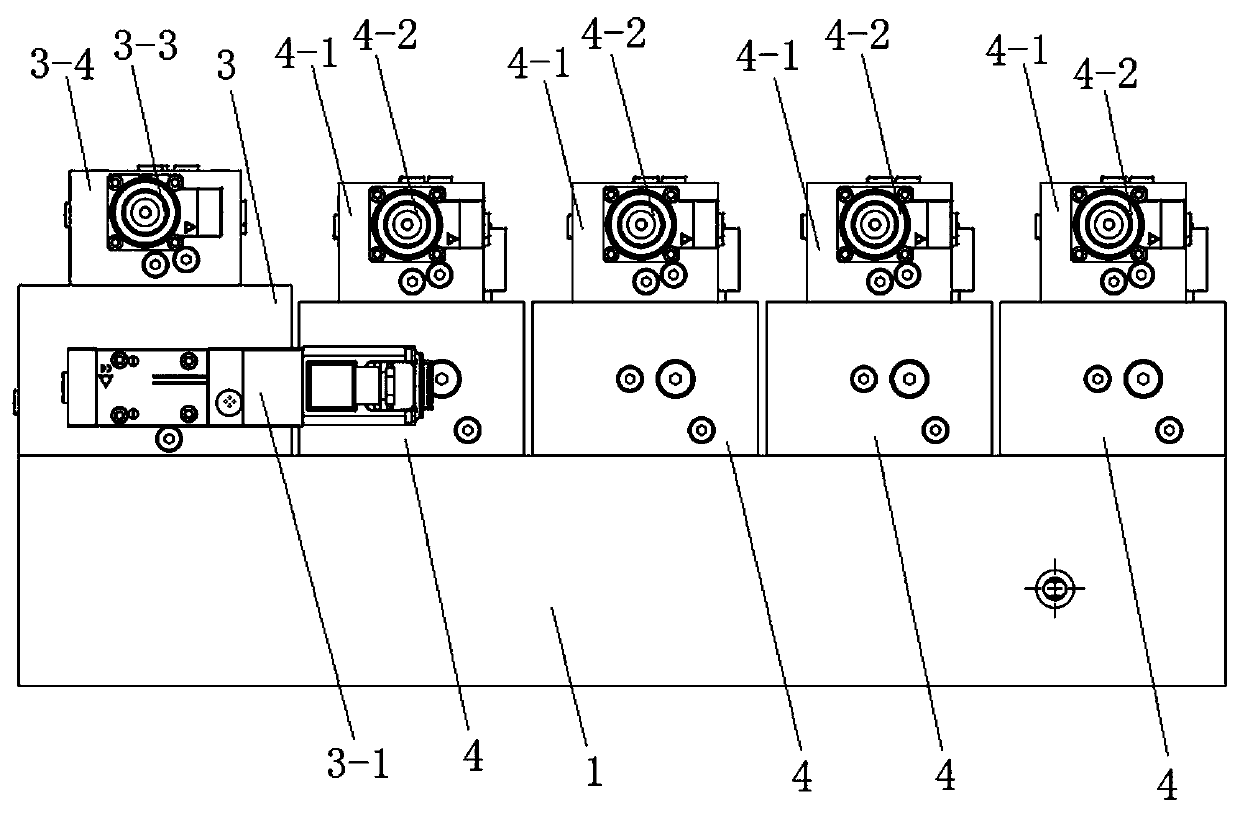

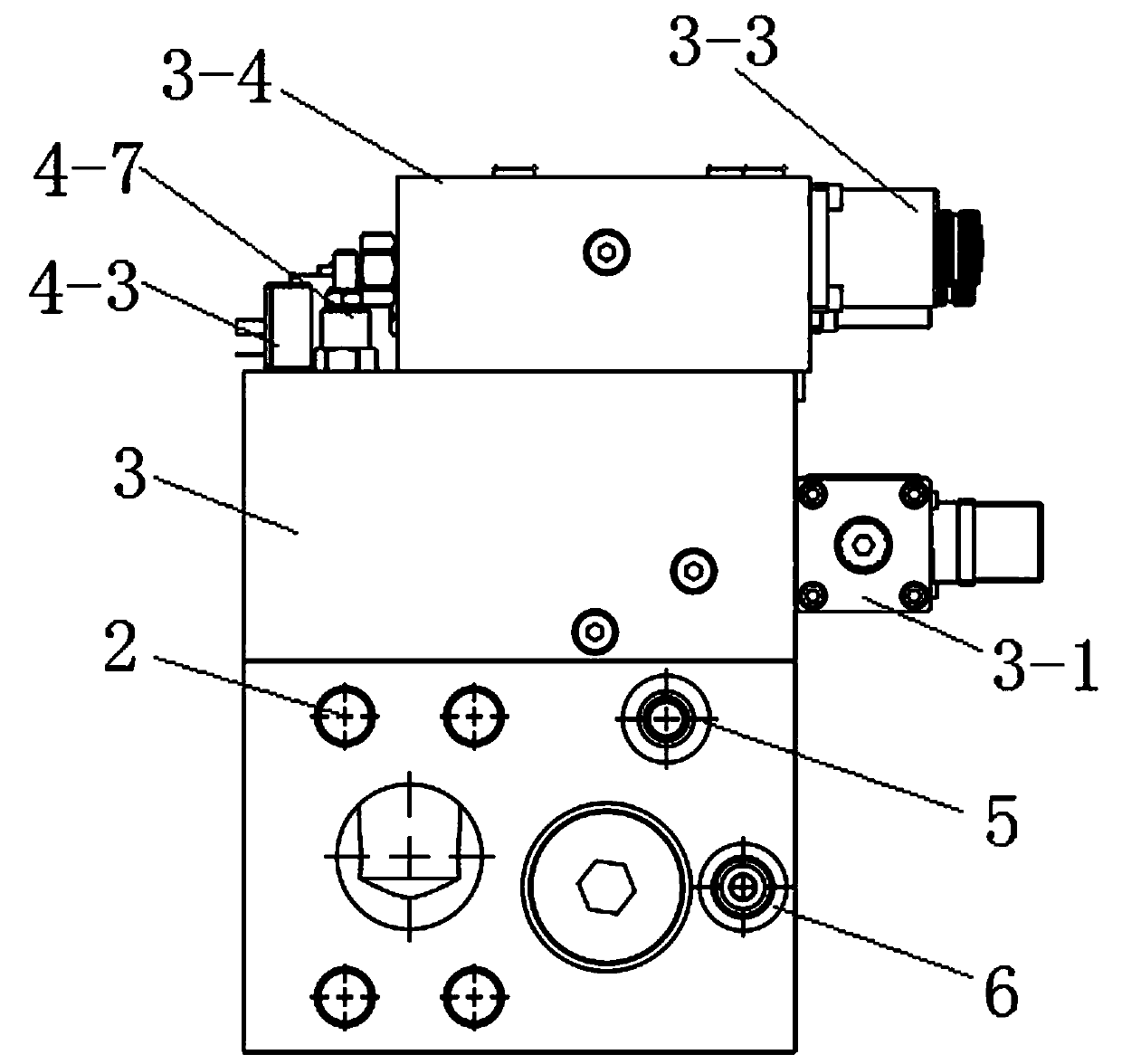

[0025] Embodiment 1, the split-type shield machine hydraulic propulsion control valve group that is easy to assemble, such as figure 2 image 3 As shown, the valve block base 1 is included, and the valve block base 1 is provided with a general oil inlet oil passage 2 and a general oil discharge oil passage 5 . Such as figure 1 As shown, the total oil inlet passage 2 includes a first oil inlet passage 2-1 and a second oil inlet passage 2-2, and the first oil inlet passage 2-1 and the second oil inlet passage 2- 2 is connected with the first joint control block 3. The first control block 3 is the opening and closing assembly of the entire control valve group, which controls the opening and closing of the oil circuit of the entire valve block.

[0026] The first joint control block 3 includes a proportional pressure reducing valve 3-1 connected between the first oil inlet oil passage 2-1 and the second oil inlet oil passage 2-2, and the proportional pressure relief valve 3-1 ...

Embodiment 2

[0031] Embodiment 2, the split-type shield machine hydraulic propulsion control valve group that is easy to assemble, such as figure 1 As shown, the first-connected control block 3 includes the first-connected three-way electromagnetic directional valve 3-3 and the first-connected cartridge valve 3-4 connected to the control unit, the first-connected three-way electromagnetic directional valve 3-3 and the first-connected plug-in valve The oil inlet of the installation valve 3-4 is connected in parallel with the first oil inlet passage 2-1, and the first oil inlet passage 2-1 can synchronously feed the first three-way electromagnetic reversing valve 3-3 and the first cartridge valve 3-4 for oil supply. The oil outlet of the first three-way electromagnetic reversing valve 3-3 is connected to the control port of the first-connected cartridge valve 3-4, and the oil return port of the first three-way electromagnetic reversing valve 3-3 is connected to the main drain oil passage 5 ...

Embodiment 3

[0033] Embodiment 3, the split-type shield machine hydraulic propulsion control valve group that is easy to assemble, such as figure 1 As shown, the oil inlet of the control-linked cartridge valve 4-1, the oil inlet of the control-linked three-way electromagnetic reversing valve 4-2 and the oil outlet of the control-linked cartridge valve 4-1 are provided with The control-linked double-ball shuttle valve 4-5, the first oil inlet of the control-linked double-ball shuttle valve 4-5 is connected with the oil inlet of the control-linked cartridge valve 4-1, and the first oil inlet of the control-linked double-ball shuttle valve 4-5 The second oil inlet is connected to the oil outlet of the control unit cartridge valve 4-1, and the oil outlet of the control unit double ball shuttle valve 4-5 is connected to the oil inlet of the control unit three-way electromagnetic reversing valve 4-2 . The control-linked double-ball shuttle valve 4-5 is capable of high-pressure selection, and ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com