Shaft hoist load simulation hydraulic loading test device

A mine hoist and load simulation technology, which is applied to fluid pressure actuation devices, fluid pressure actuation system testing, mechanical equipment, etc. Short and other problems, to achieve the effects of excellent speed regulation performance, easy commutation, convenient and flexible control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

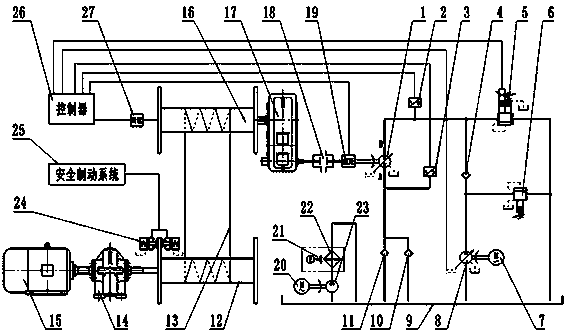

[0018] like figure 1 As described above, a mine hoist load simulation hydraulic loading test device provided by the present invention includes a hoist main lifting mechanism and a safety braking system, wherein a mine hoist hydraulic loading test mechanism is additionally provided, including an accompanying test paper barrel 16, speed increaser 17, hydraulic pump / motor 1, high-pressure pressure sensor 2, low-pressure pressure sensor 3, proportional relief valve 5 and torque sensor 17; wherein, the shaft end of the motor 7 and the shaft end of the hydraulic pump 8 The oil inlet of the hydraulic pump 8 is connected to the oil tank 9 through the pipeline, the oil outlet of the hydraulic pump 8 is connected to the oil inlet of the relief valve 6 and the high-pressure check valve 4 through the pipeline, and the high-pressure check valve 4 is connected through the pipeline They are respectively connected to the oil inlet of proportional relief valve 5, high pressure sensor 3, and oi...

Embodiment 2

[0021] Embodiment 2. The hydraulic pump / motor 1 adopts a fixed-displacement pump or a variable-displacement pump.

Embodiment 3

[0022] Embodiment 3. The proportional overflow valve 5 adopts a pilot-operated overflow valve or a direct-acting overflow valve.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com