A biomass semi-gasifier

A semi-gasification and biomass technology, which is used in the chemical industry, household stoves/stoves, and the manufacture of combustible gases, etc., can solve problems such as the inability of the outer flame to reach the bottom of the cooker, the unfavorable heat absorption of the cooker, and the low utilization rate of heat, so as to achieve fire Fast, energy-saving effect, good combustion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

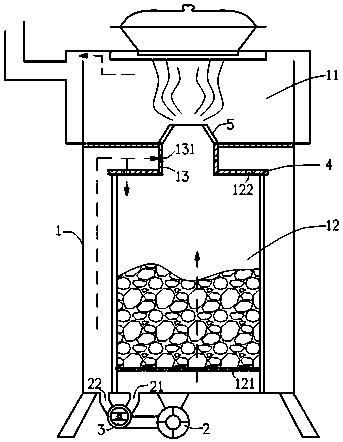

[0020] Below, the embodiments of the present invention will be further described in conjunction with the accompanying drawings.

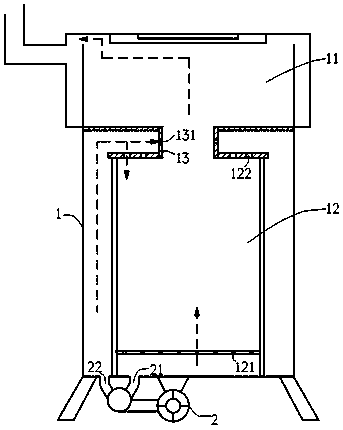

[0021] figure 1 It shows an embodiment of the first biomass semi-gasification furnace, which includes a furnace body 1, a combustion chamber 11 is arranged on the upper part of the furnace body 1, and a gasification chamber 12 is arranged on the lower part of the furnace body 1, and the gasification chamber 12 and the combustion chamber 11 are connected through a guide. The flow pipes 13 are connected; the fan 2 is connected to the main air duct 21 and the secondary air duct 22, and the main air duct 21 is connected to the main air hole 121 of the gasification chamber 12, and the main air hole 121 is located at the bottom of the gasification chamber 12; The secondary air hole 122 of the gasification chamber 12 is located at the top of the gasification chamber 12 ;

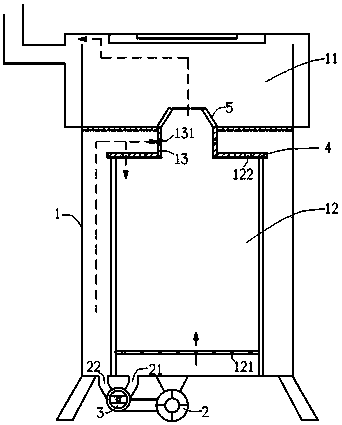

[0022] figure 2 It shows the embodiment of the second biomass semi-gasification f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com