Layered liquid settling tank for production sewage of modifying agent

A technology for the production of sewage and modifiers, applied in the direction of settlement tanks, etc., can solve the problems of high maintenance costs, delay in production, and large floor area, and achieve the effect of reducing the content of settleables and improving settlement, and occupying a small area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

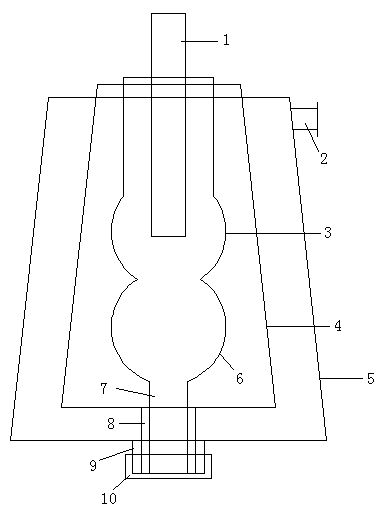

[0011] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the following specific embodiments are only used to illustrate the present invention but not to limit the scope of the present invention. It should be noted that the words "front", "rear", "left", "right", "upper" and "lower" used in the following description refer to the directions in the drawings, and the words "inner" and "outer ” refer to directions towards or away from the geometric center of a particular part, respectively.

[0012] It can be seen in conjunction with the accompanying drawings that the laminar liquid settling tank used for the production of sewage by this modifier comprises a liquid inlet pipe 1, a liquid inlet tank 3, an intermediate tank 4 and an outer layer tank 5, and a sediment tank 6 is provided below the liquid inlet tank 3 for feeding The liquid tank 3 and the sediment tank 6 are suspend...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com