A device and method for enrichment and separation of fluorine-containing polymer emulsion

A polymer emulsion and fluoropolymer technology, applied in chemical instruments and methods, mixers with rotating stirring devices, mixers, etc., can solve problems such as poor process stability, high industrial production costs, and large filter cake resistance. Achieve stable operation, good enrichment and separation effect, and reduce load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

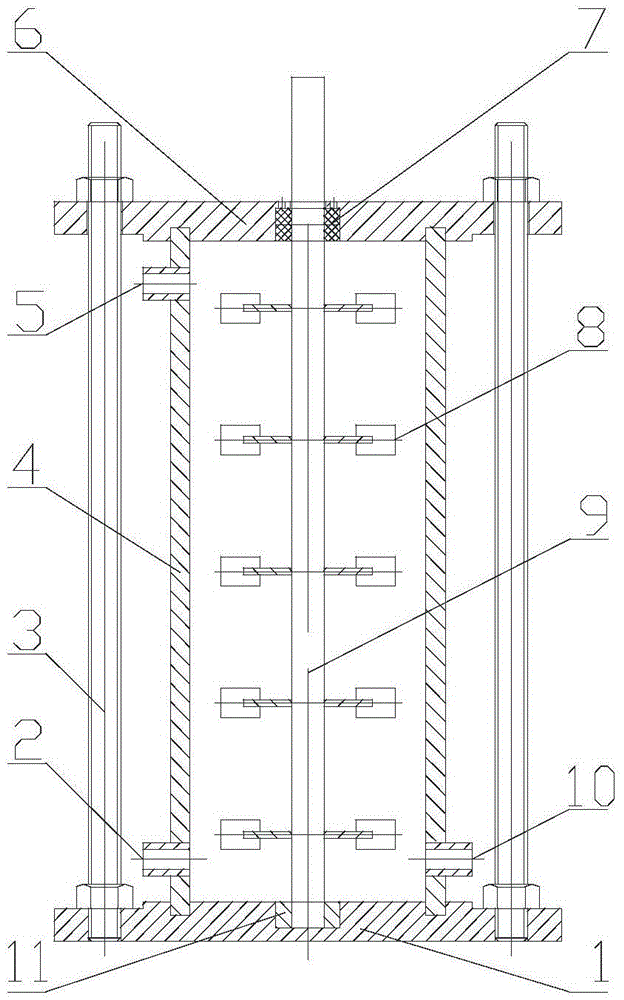

[0029] A fluorine-containing polymer emulsion enrichment and separation device, its structure is as follows figure 1 As shown, the device includes a lower end cover 1, a feed pipe 2, a fastening part 3, a cylinder body 4, a discharge pipe 5, an upper end cover 6, an upper end cover shaft seal 7, a stirring blade 8, a stirring shaft 9, and an air intake pipe 10. Lower end cover shaft sleeve 11 and other components. The upper and lower ends of the cylinder 4 are respectively provided with an upper end cover 6 and a lower end cover 1 , and the upper end cover 6 and the lower end cover 1 are connected to the cylinder 4 through a fastening part 3 . The upper end cover 6 and the lower end cover 1 are respectively provided with an upper end cover shaft seal 7 and a lower end cover shaft sleeve 11 .

[0030] The feed pipe 2, the air inlet pipe 10 and the discharge pipe 5 are connected to the cylinder body 4, the feed pipe 2 and the air inlet pipe 10 are located at the bottom of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com