Process for ore pulp desliming and ore slurry dehydration

A slurry and desliming technology, applied in chemical instruments and methods, solid separation, wet separation, etc., can solve the problems of complex desliming process and poor effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

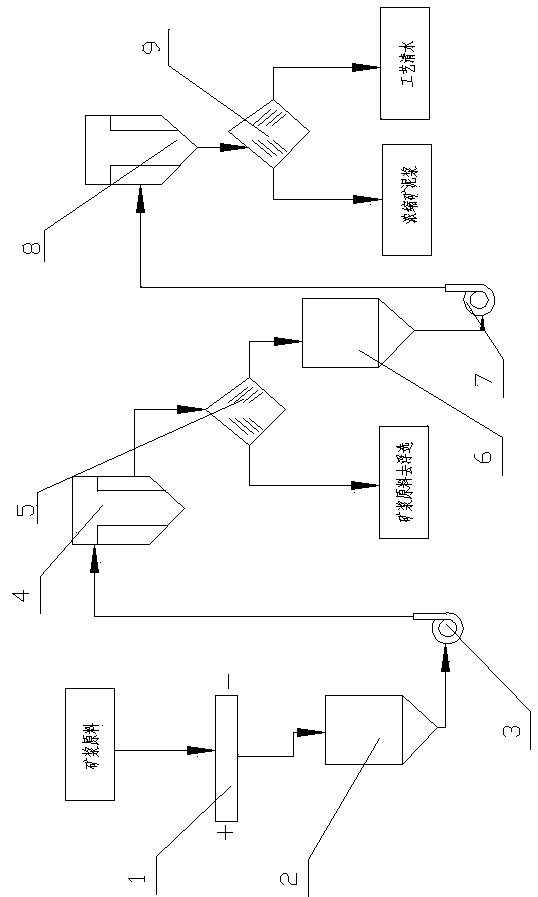

[0008] Attached below figure 1 Specifically illustrate the implementation steps of the present invention:

[0009] a. Pass the pulp raw material through the slag separation screen 1 to remove the large slag, and send it into the pulp tank 2 after removing the large slag;

[0010] b. Input the pulp raw material in the pulp tank 2 into the sorting filter 4 to remove impurities through the pulp feeding pump 3;

[0011] c. The ore pulp raw material that has been removed by the sorting filter 4 is input into the sorter 5 for desliming and selection to obtain deslimed ore pulp and ore slurry. The deslimed ore slurry enters the flotation process, and the ore slurry is sent to the ore slurry tank 6 ;

[0012] d, the ore slurry in the ore slurry tank 6 enters the dewatering filter 8 through the ore slurry feed pump 7 to remove impurities, and the ore slurry enters the dehydrator 9 after the dewatering filter 8 removes impurities to concentrate and dehydrate, so as to obtain concentra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com