An aluminum ingot demoulding mechanism

A demoulding mechanism and aluminum ingot technology, applied in pig iron casting workshops, manufacturing tools, casting workshops, etc., can solve problems such as low yield, difficulty in demoulding aluminum ingots, low production efficiency, etc., and achieve long service life and low raw material resources. High utilization rate and good product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

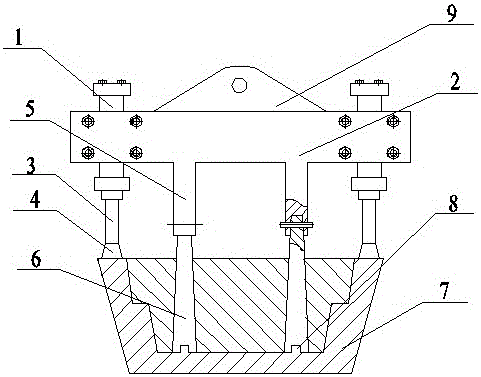

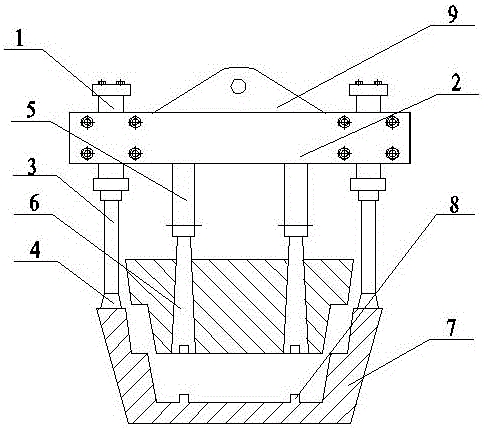

[0016] As shown in the figure, an aluminum ingot demoulding mechanism of the present invention includes a casting mold 7 and a demoulding device. The demoulding device includes a beam frame 2, a hydraulic cylinder 1 symmetrically arranged at both ends of the beam frame 2 and a 1 The supporting hydraulic push rod 3, the hydraulic power unit has a compact structure, good reliability, small power input, large output force, easy operation and control, and a high degree of automation. The setting position of the hydraulic push rod 3 corresponds to the top of the side wall of the casting mold 7, and the end of the hydraulic push rod 3 is also provided with a cone 4, which directly contacts the end of the casting mold 7, and the cone 4 is the lower thick The thin structure, which is arranged at the end of the hydraulic push rod 3, can greatly increase the contact area between the power device and the mold 7, so that the stability of the demoulding process is enhanced, the local stress...

Embodiment 1

[0019] An aluminum ingot demoulding mechanism, comprising a casting mold 7 and a demoulding device, the demoulding device comprising a beam frame 2, a hydraulic cylinder 1 symmetrically arranged at both ends of the beam frame 2, and a hydraulic push rod 3 matched with the hydraulic cylinder 1, The setting position of the hydraulic push rod 3 corresponds to the top of the side wall of the mold 7, and the demoulding device also includes a conical shaft 6 with a groove at the large radius end, and the inner bottom surface of the mold 7 is provided with the conical shaft 6. The positioning boss 8 matched with the groove at the large radius end, the positioning column 5 is fixed on the beam frame 2, the lower part of the positioning column 5 is detachably connected with the small radius end of the conical shaft 6, and the end of the hydraulic push rod 3 A cone 4 in contact with the casting mold 7 is also provided.

[0020] The inner cavity of the casting mold 7 is a rectangular pyr...

Embodiment 2

[0026] An aluminum ingot demoulding mechanism, comprising a casting mold 7 and a demoulding device, the demoulding device comprising a beam frame 2, a hydraulic cylinder 1 symmetrically arranged at both ends of the beam frame 2, and a hydraulic push rod 3 matched with the hydraulic cylinder 1, The setting position of the hydraulic push rod 3 corresponds to the top of the side wall of the mold 7, and the demoulding device also includes a conical shaft 6 with a groove at the large radius end, and the inner bottom surface of the mold 7 is provided with the conical shaft 6. The positioning boss 8 matched with the groove at the large radius end, the positioning column 5 is fixed on the beam frame 2, the lower part of the positioning column 5 is detachably connected with the small radius end of the conical shaft 6, and the end of the hydraulic push rod 3 A spring body in contact with the casting mold 7 is also provided.

[0027] The inner cavity of the casting mold 7 is a rectangula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com