Arc jet nozzle for producing amorphous thin belt

A technology of arc-shaped nozzles and thin strips, which is applied in the direction of casting molten material containers, manufacturing tools, metal processing equipment, etc., can solve the problems of poor strip surface at the edge of the strip, slow replacement speed of molten steel, and lower temperature of molten steel, so as to achieve no eddy current , simple structure, uniform exchange of molten steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

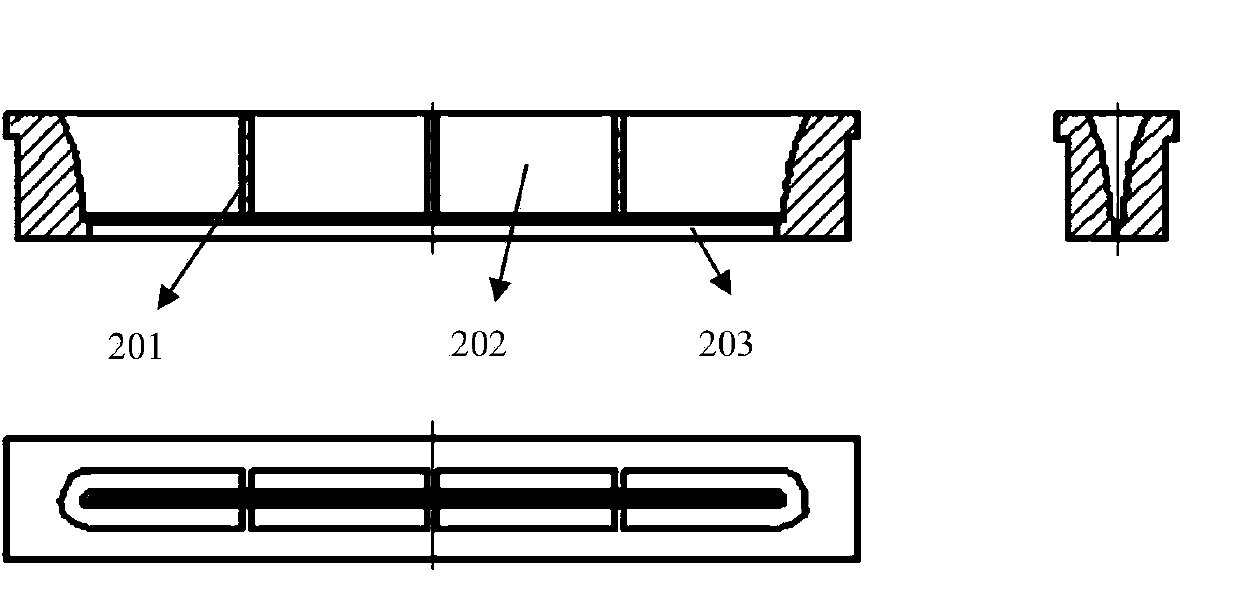

[0011] The present invention optimizes the internal structure of the nozzle in the prior art, and the nozzle uses boron nitride as the raw material for the nozzle, such as figure 2 As shown, the middle of the block material is horizontally hollowed out to form a cavity 202, and three supporting ribs 201 are reserved in the hollowed out part. In a specific embodiment, the edges of the cavity near the four vertical sides of the arc-shaped nozzle are all in the shape of a convex arc streamline. A spraying slot 203 is processed below the cavity, the length of the spraying slot is determined by the width of the produced strip, and the width of the spraying slot is in the range of 0.3-0.9 mm. In a specific embodiment, the four inner corners of the curved nozzle cavity located on the four vertical sides of the curved nozzle are also curved, so as to avoid the formation of right-angled structures in the prior art when flowing through molten metal. Dead zones and vortex phenomena.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com