Glass fiber reinforced polyurethane/paper honeycomb sandwich composite car sleeper board and its preparation process

A preparation process, paper honeycomb technology, applied in vehicle parts, special positions of vehicles, transportation and packaging, etc., can solve problems such as water seepage and moisture absorption, poor resilience, warping and deformation, and achieve good rigidity, low density, and weight. light effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

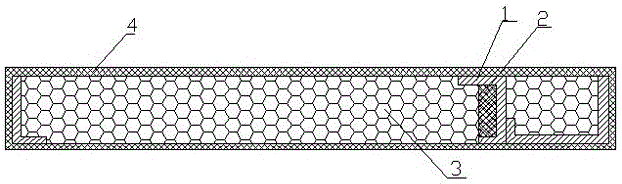

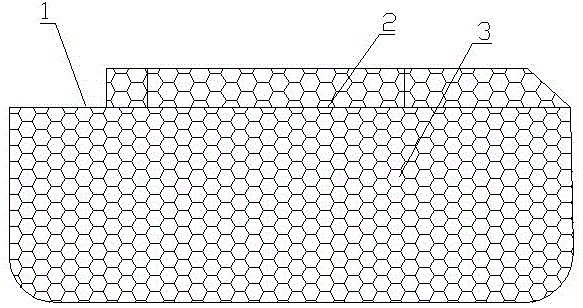

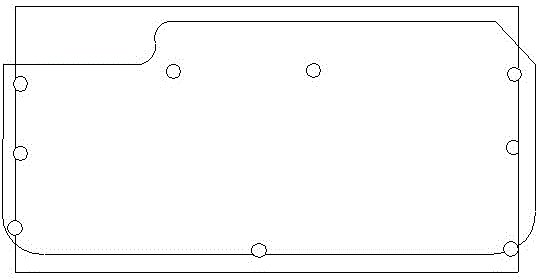

[0028] see figure 1 and figure 2 , The present invention relates to a glass fiber reinforced polyurethane / paper honeycomb sandwich composite car sleeper board, comprising a sleeper frame 1, the sleeper frame 1 is an iron frame, which is composed of C-shaped steel plates and L-shaped steel plates spliced together. The C-shaped steel plate is embedded with bamboo slats 2 to improve the strength of the sleeper frame 1, and the sleeper frame 1 is embedded with honeycomb paper 3, and the outer layer of the sleeper frame 1 is provided with a mixed layer of PU and glass fiber, so as to The role of curing sleeper boards.

[0029] The preparation process of this glass fiber reinforced polyurethane / paper honeycomb sandwich composite car sleeper board is as follows:

[0030] 1. Stretch forming: Use a honeycomb paper stretching machine, set the temperature at 120°C, stretch the honeycomb paper to a size of 2100mm*680mm, and the honeycomb holes are regular hexagons.

[0031] 2. Cutti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com