Cutting process method of touch screen

A technology of cutting processing and touch screen, which is applied in the direction of glass cutting devices, manufacturing tools, glass manufacturing equipment, etc. It can solve the problems of complete product breakage, limited production capacity, and difficult cutting wheel, so as to reduce the intermediate process flow, avoid damage and Time-consuming, the effect of improving product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below in combination with specific embodiments and with reference to the accompanying drawings.

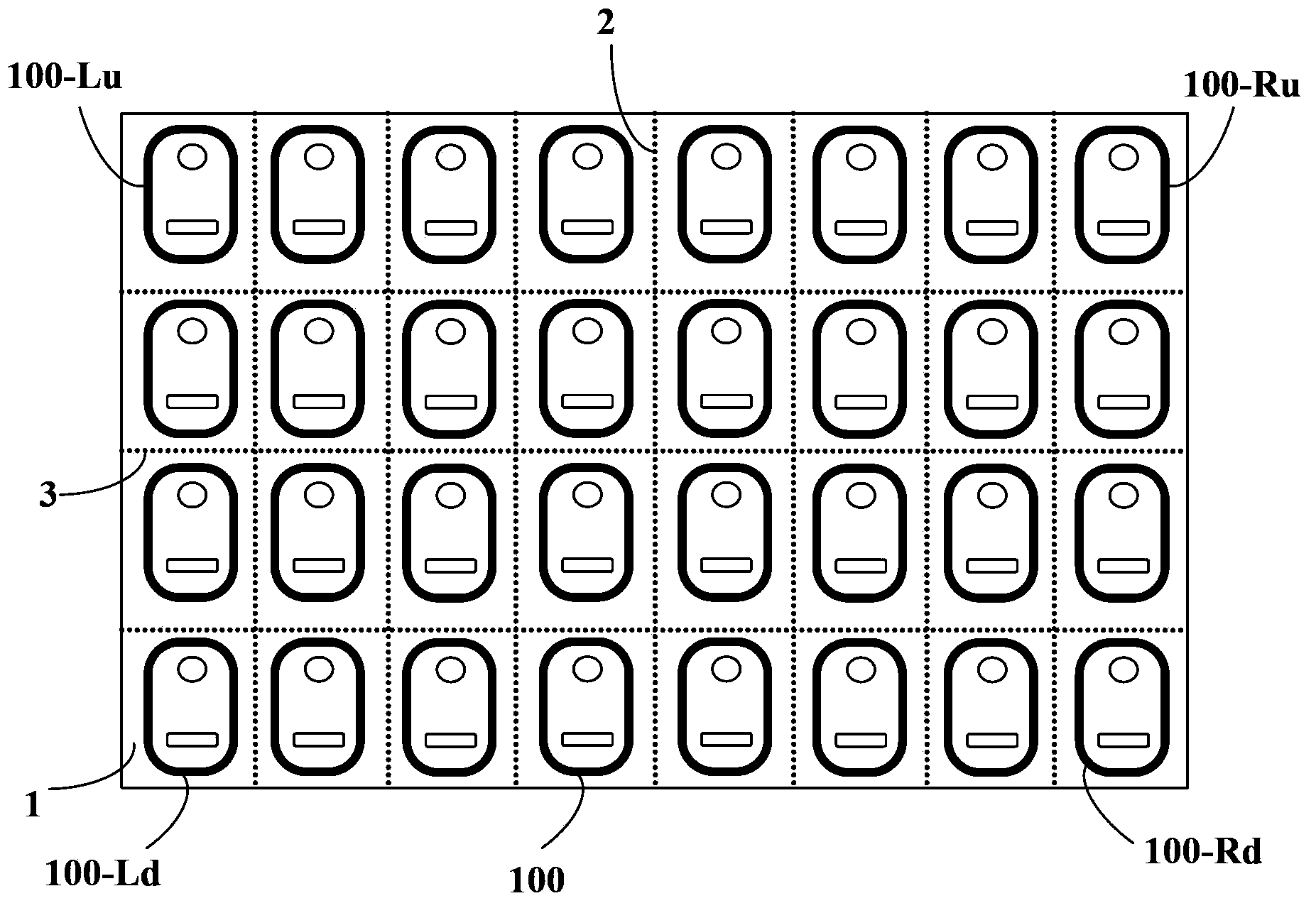

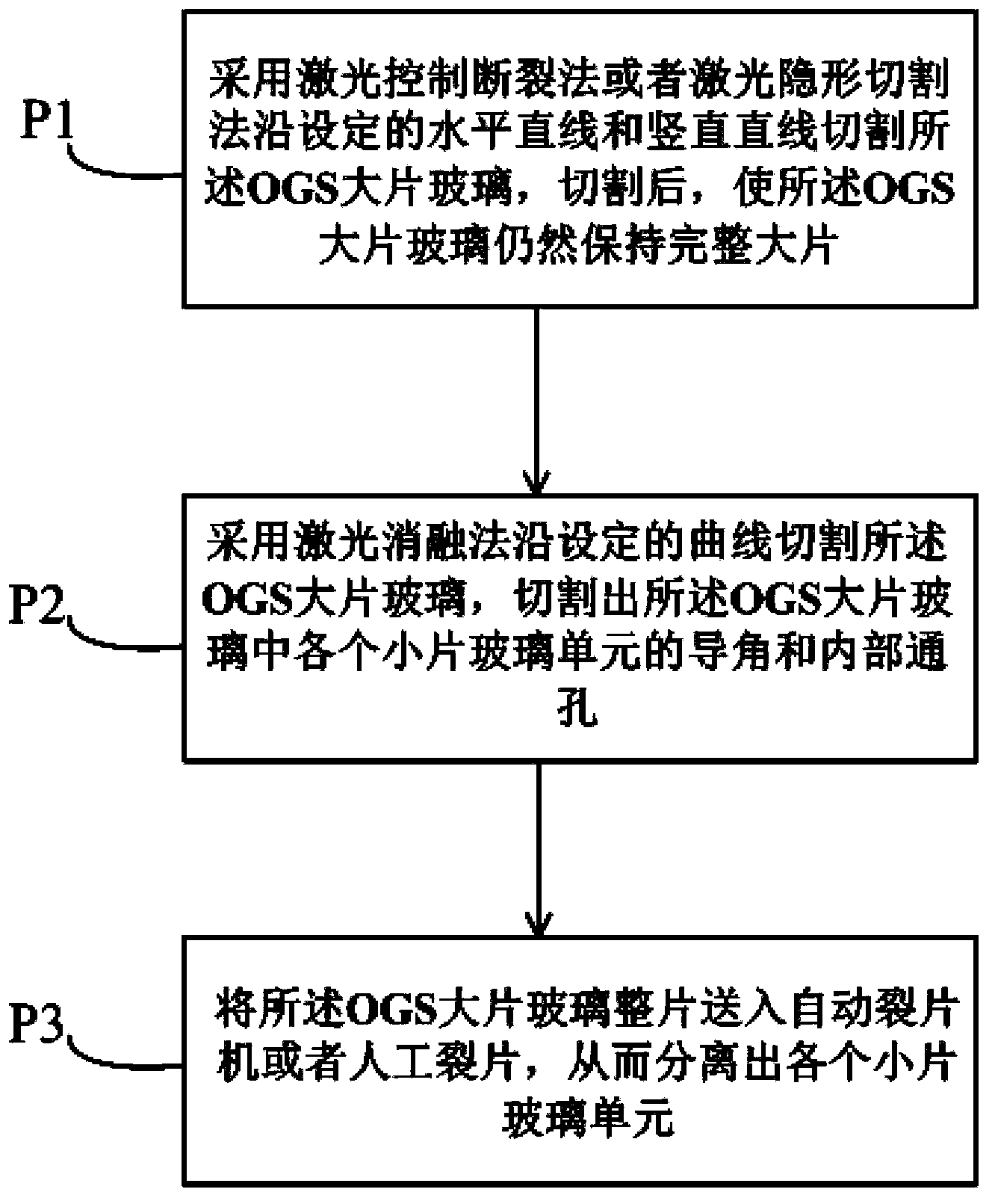

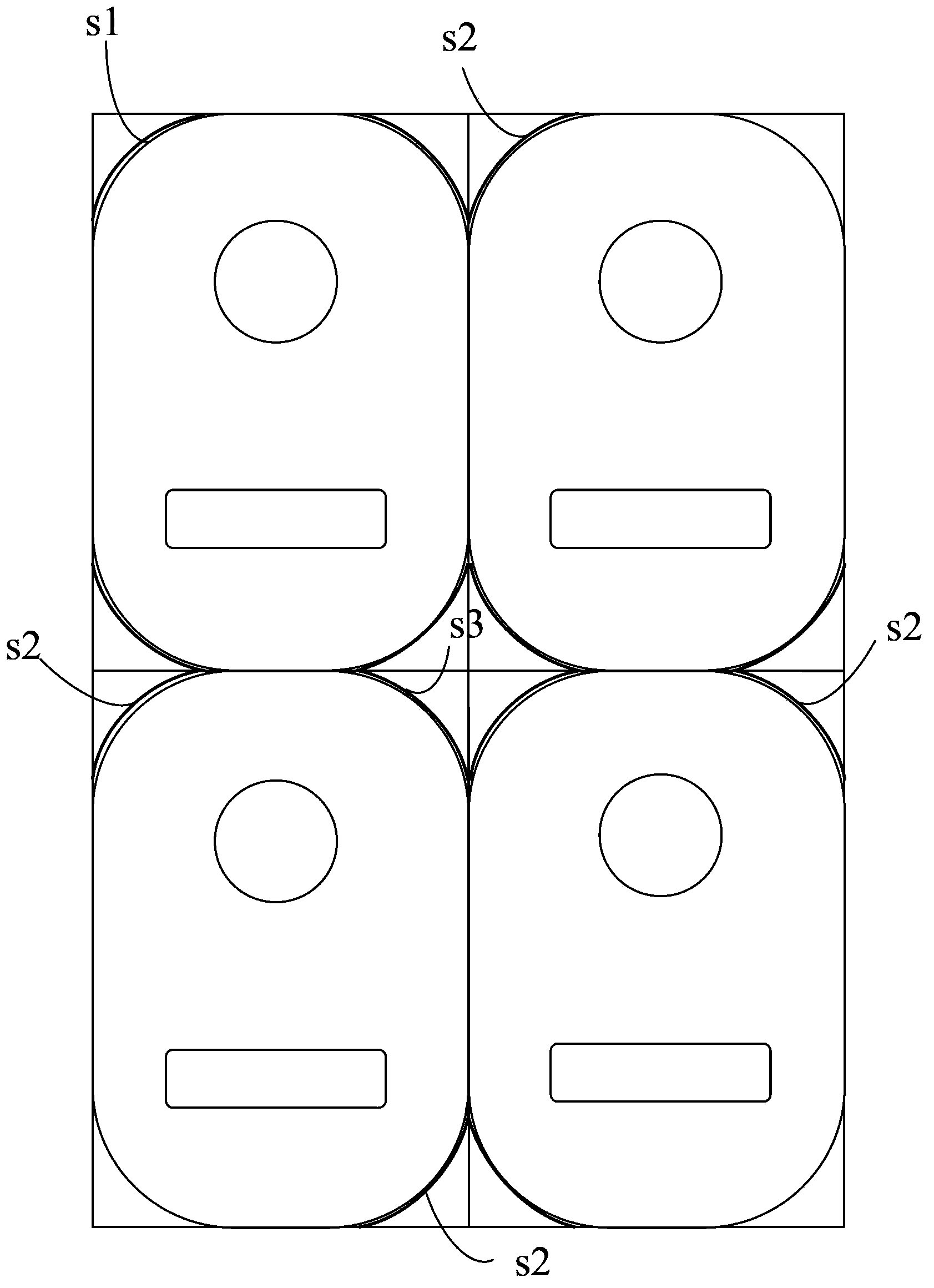

[0015] The present invention proposes a solution to the problem of low efficiency and low product yield in the process of cutting strengthened glass with a knife wheel in the existing OGS large-scale production method. According to the advantages and disadvantages of various laser cutting technologies, these processes are integrated and the advantages are complementary. Use advantageous processing technologies at different stations to improve production efficiency, product yield, product strength, and reduce use costs. The main difference between the cutting and processing method of a touch screen in the present invention and the traditional technology is that it uses a combination of multiple laser cutting glass technologies to replace the traditional knife wheel cutting and CNC drilling methods. This solution uses m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com