Installation method for wall grounding plate

An installation method and site technology, which are applied in the direction of connecting contact materials, buildings, building structures, etc., can solve the problems of failure of the support system, deep sinking of the casting ground plate 2, and failure to find it, so as to shorten the installation time and reduce the construction time. cost, the effect of improving the quality of installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the present invention more comprehensible, preferred embodiments are described in detail below with accompanying drawings.

[0024] combine Figure 4 , a kind of wall ground plate installation method provided by the present invention, its steps are:

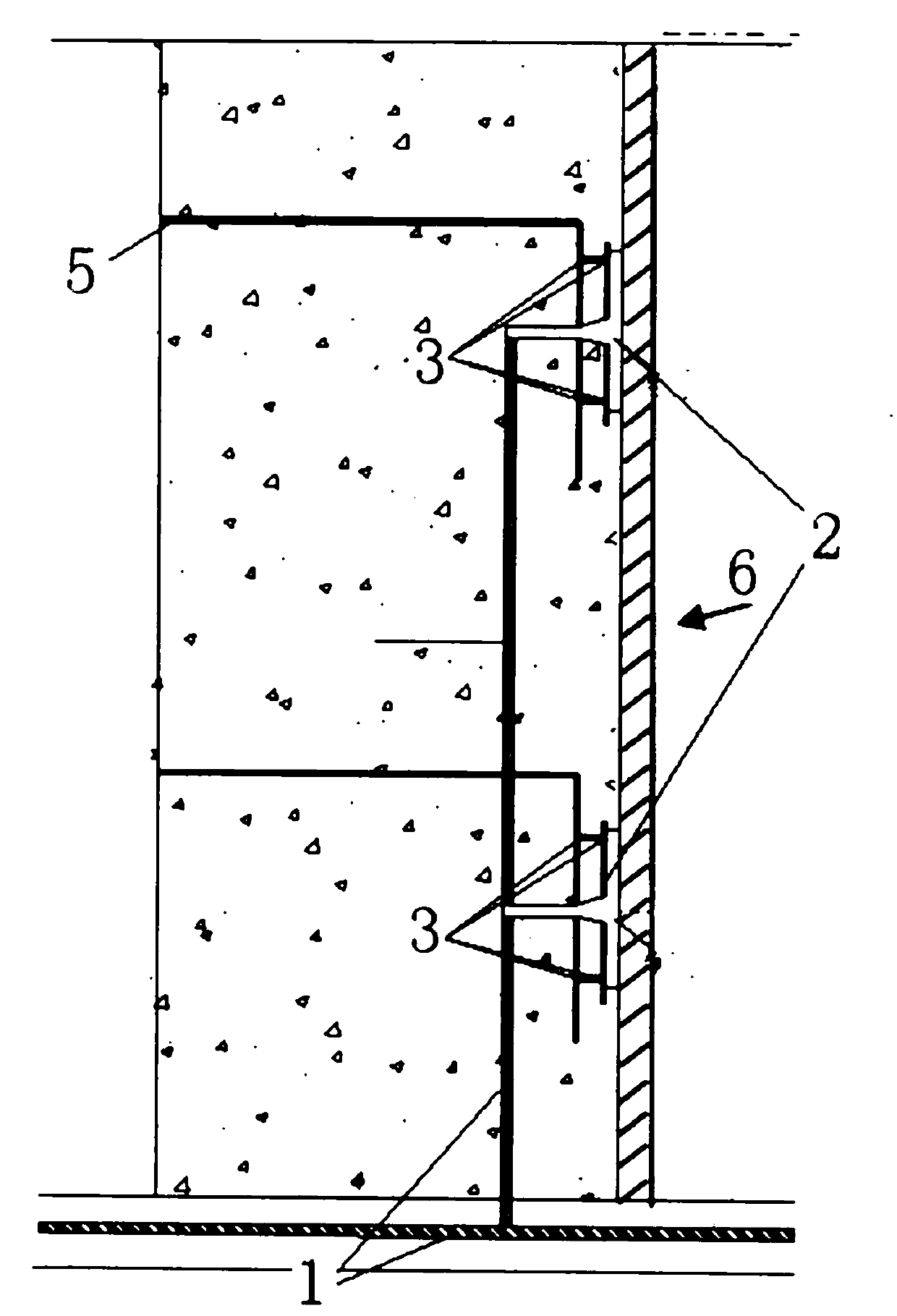

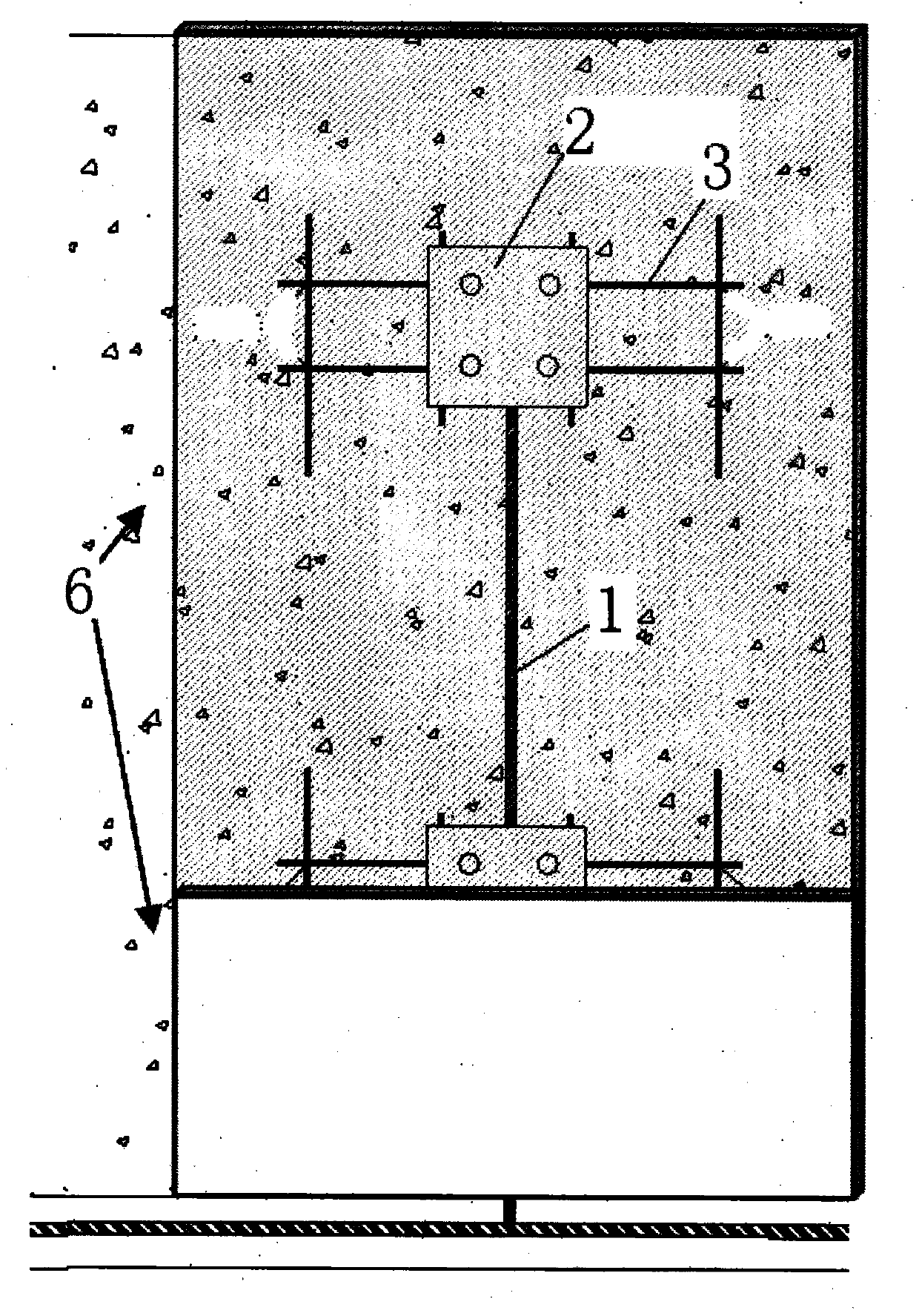

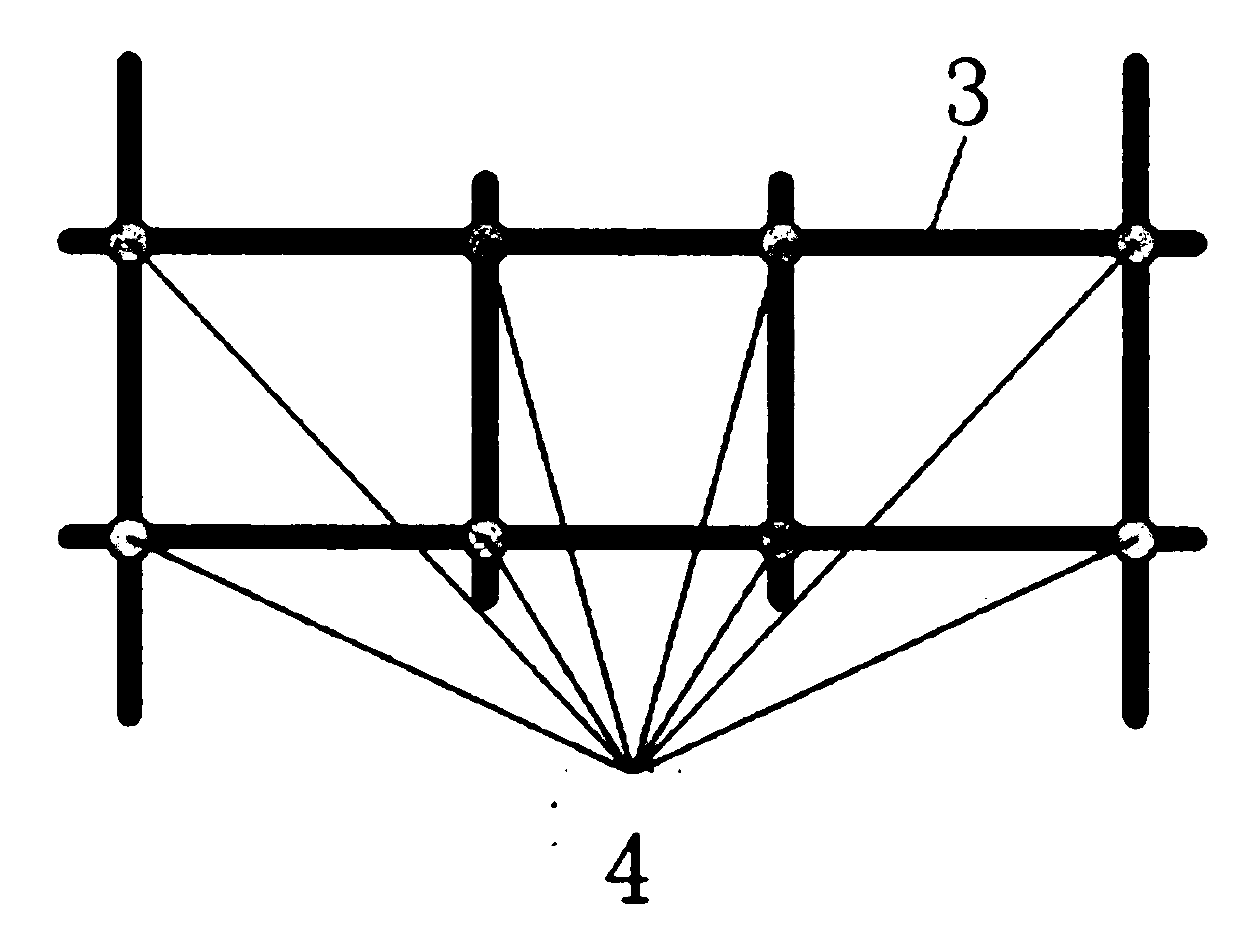

[0025] Step 1. Lay the grounding copper cable 1 after the wall reinforcement is bound, and weld the grounding copper cable 1 and the casting grounding plate 2 by exothermic welding;

[0026] Step 2. According to the installation position of the casting grounding plate 2 on the drawing, mark a number of bolt holes of the casting grounding plate 2 at the corresponding positions of the formwork 6, determine the opening position, and open the formwork 6 at the determined opening position. The hole diameter is determined according to the diameter of the bolt matching the cast grounding plate 2;

[0027] Step 3. Screw the bolts that match the casting ground plate 2 into the holes opened in step 2. After passin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com