Optical fiber conduction type rotor flow sensor

A rotor flow and sensor technology, applied in the field of optical fiber conduction rotor flow sensor, can solve the problem of inability to realize accurate instantaneous flow measurement and remote automatic adjustment of upper and lower limit positions, magnetic limit switches, magnetic field limit accuracy, and failure to meet the use requirements and other issues, to achieve the effects of long-distance transmission, manufacturing, and increasing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings.

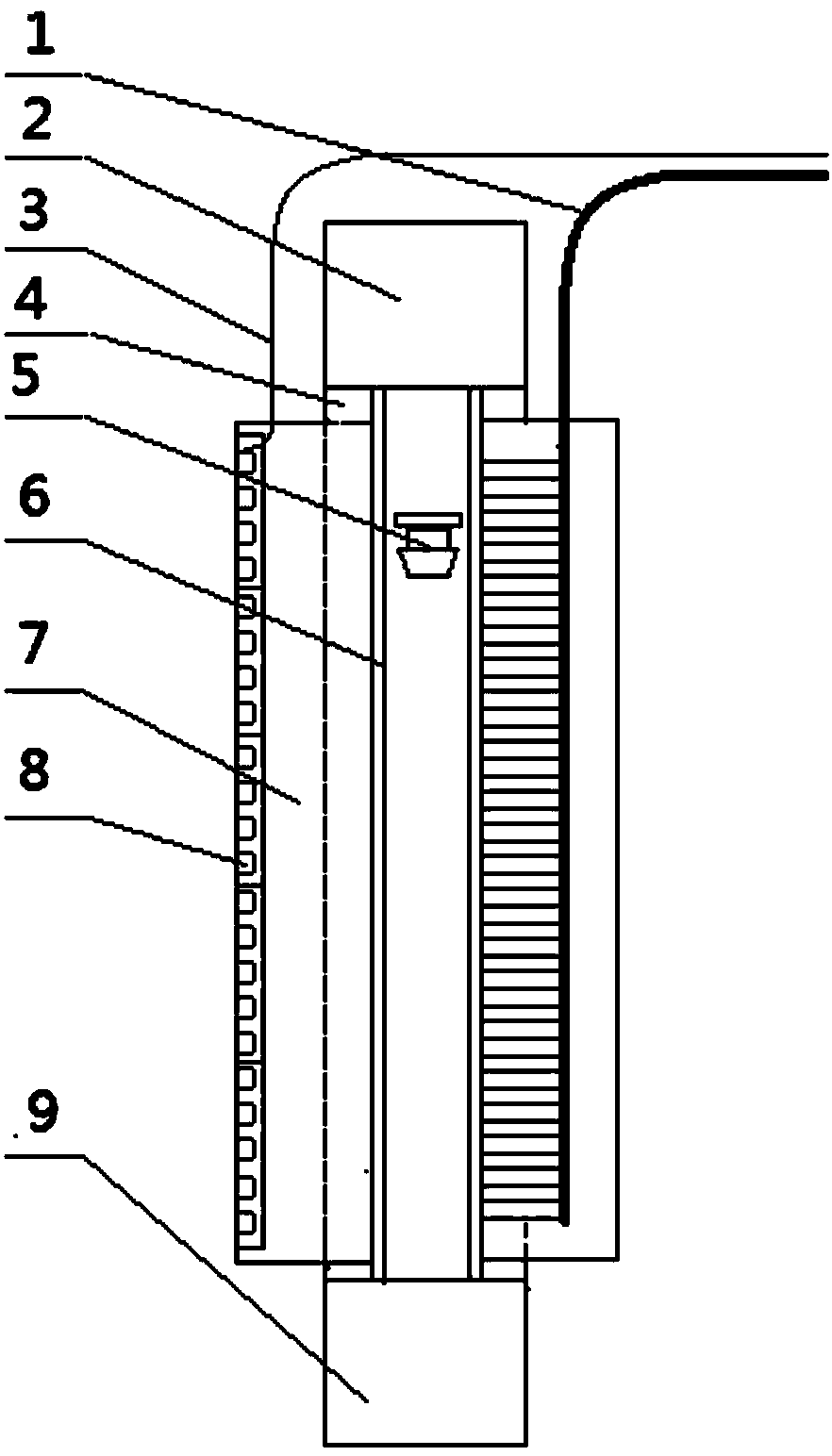

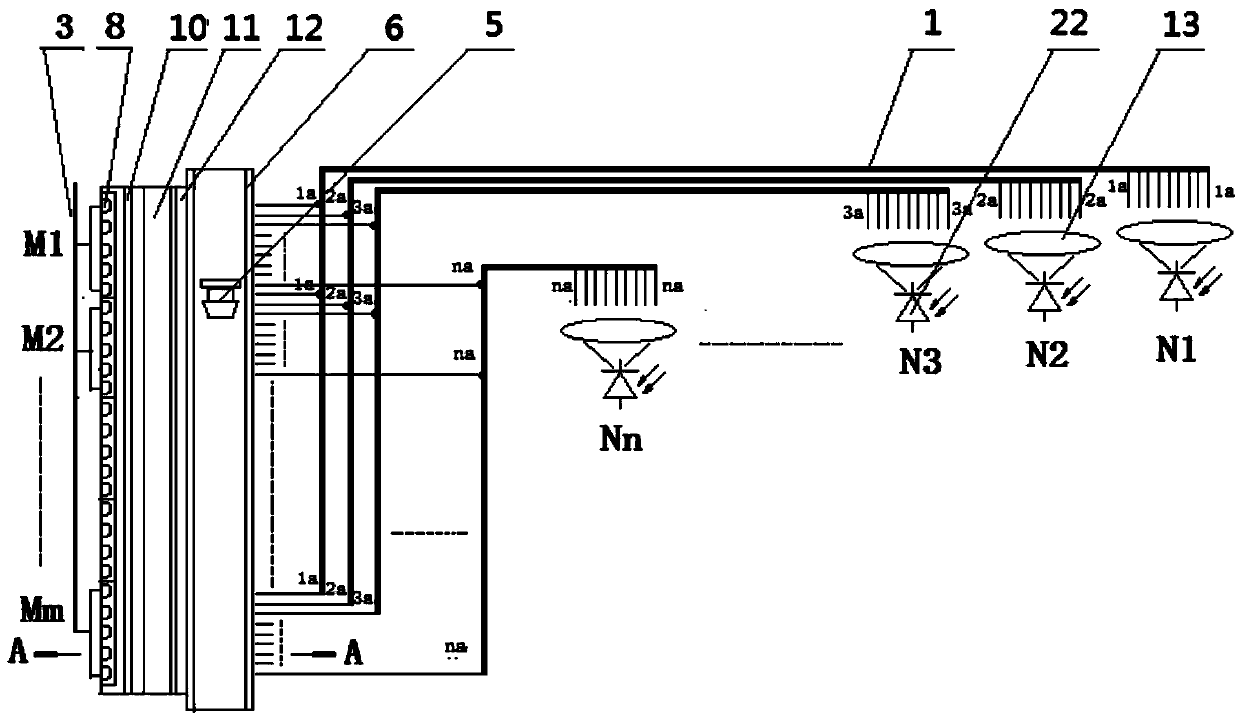

[0031] An optical fiber conduction rotor flow sensor, including a circuit system, a parallel light source, a glass rotor flowmeter, an optical fiber image transmission bundle 1 and a photodiode array, wherein,

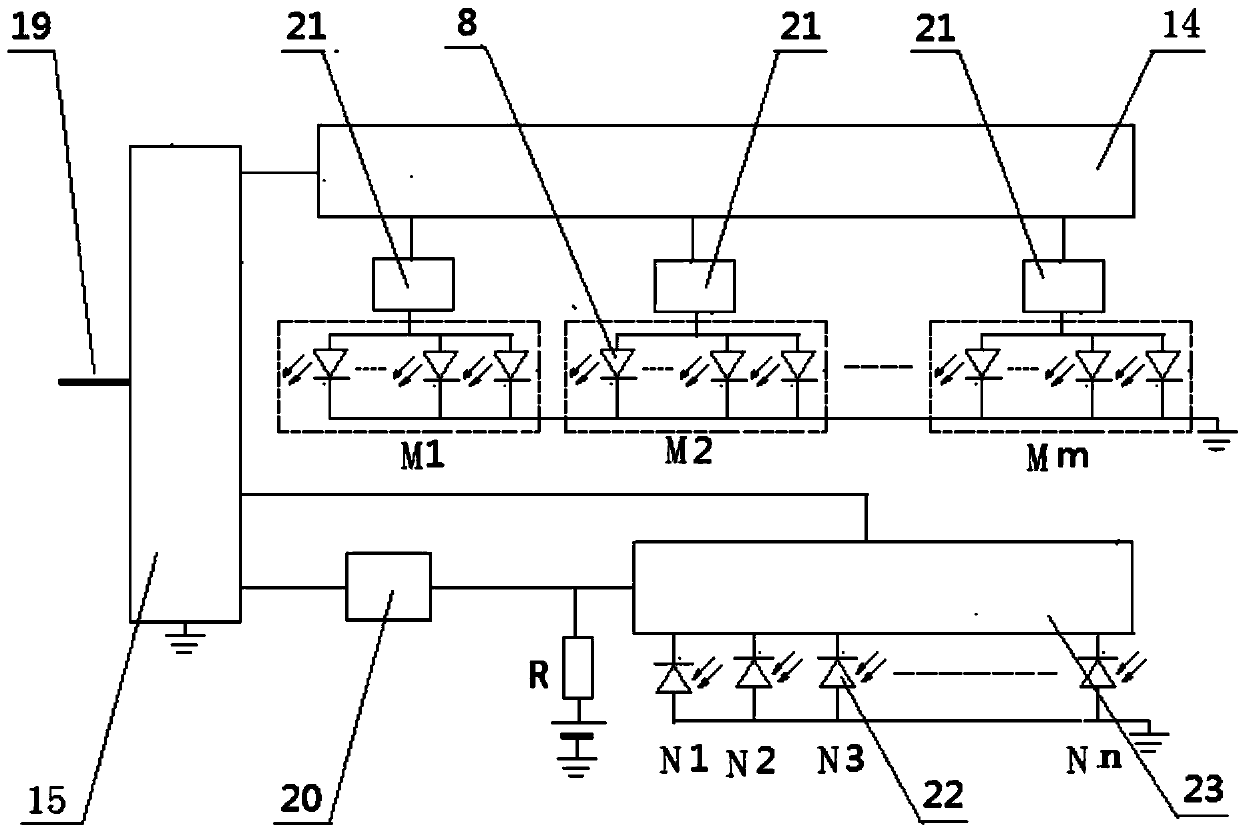

[0032] The structure of described circuit system is: comprise microprocessor 15, light source scanning circuit 14, drive circuit 21, signal processing circuit 20 and photosensitive diode scanning circuit 23, wherein, microprocessor 15 is connected with light source scanning circuit 14, light source scanning circuit 14 is connected to the LED8 through the drive circuit 21 (the drive circuit 21 is connected to the LED8 through the wire 3) (the LED8 in the LED array can be controlled to turn on and emit light sequentially through the light source scanning circuit 14); the microprocessor 15 is connected to the signal processing circuit 20, and the signal The proces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com