Manufacturing method for Ag/Al core shell composite nanometer particle light trapping structure of thin film solar cell

A technology of thin-film solar cells and composite nanoparticles, which is applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problem that the photoelectric conversion efficiency is not very significant, so as to improve the photoelectric conversion efficiency and eliminate The effect of broadening the spectral half-maximum width, simple and repeatable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

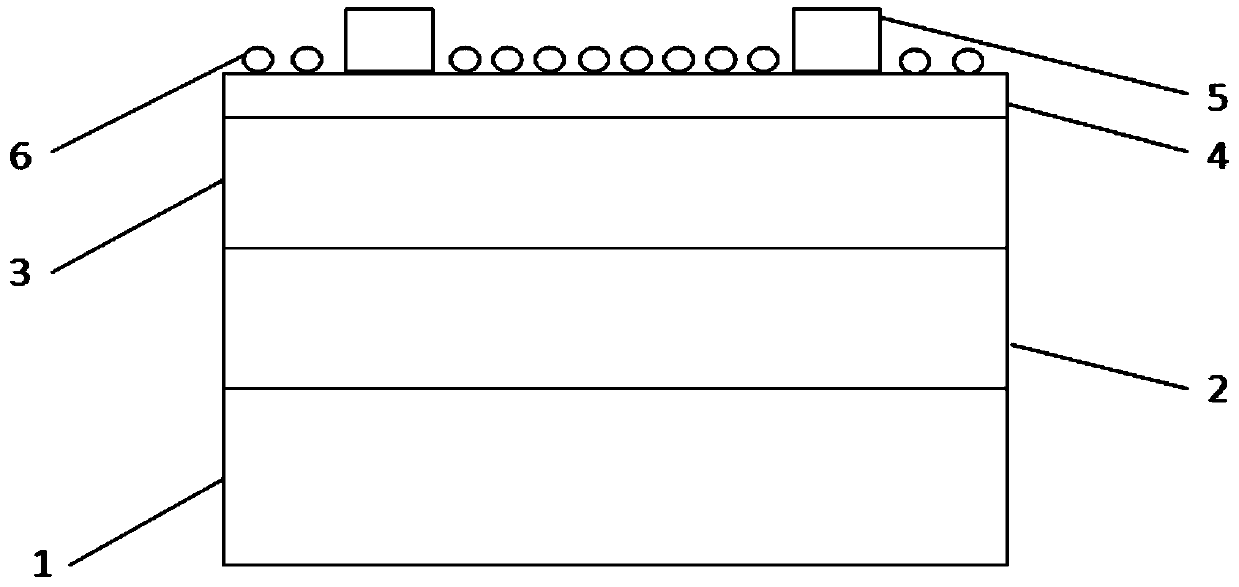

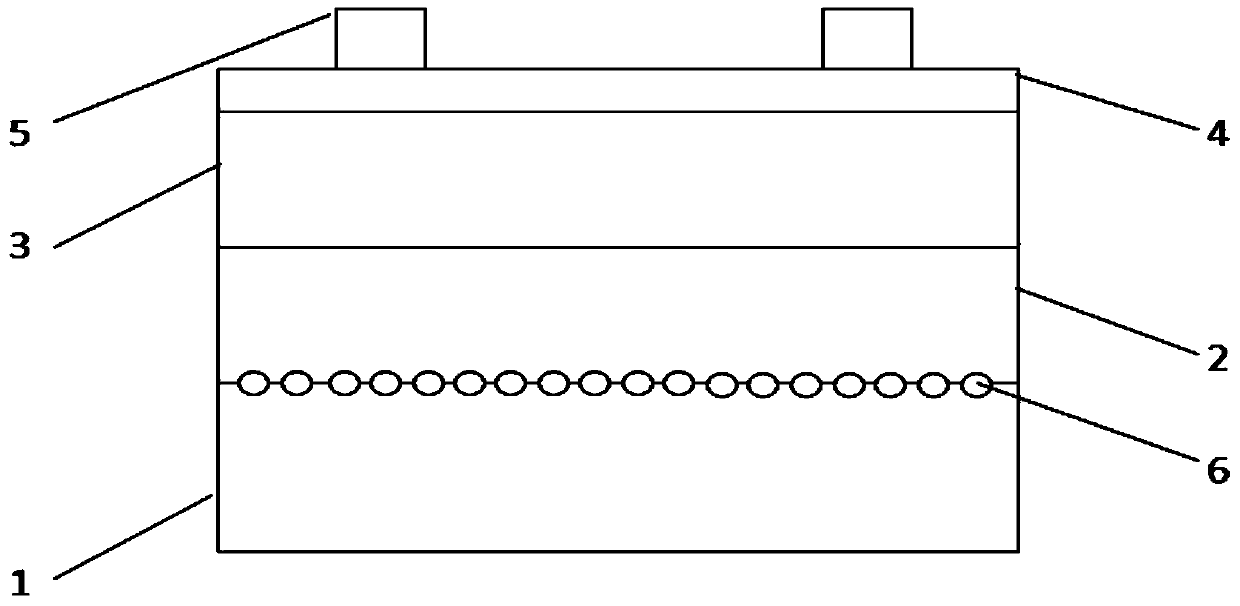

[0024] A method for preparing a thin-film solar cell Ag / Al core-shell composite nanoparticle light-trapping structure, comprising the following steps:

[0025] Step 1: Select the base material;

[0026] Step 2: Prepare an Ag thin film at room temperature by magnetron sputtering on the base material;

[0027] Step 3: performing in-situ annealing on the Ag film to form Ag core nanoparticles;

[0028] Step 4: On the base material of the prepared Ag core nanoparticles, the Al thin film is prepared at room temperature by magnetron sputtering again;

[0029] Step 5: Perform in-situ annealing on the Al film to form the Al shell nanoparticles and at the same time form the Ag / Al core-shell composite nanoparticle light-trapping structure of the thin film solar cell;

[0030] Step 6: improve the solar cell device process, and prepare a thin film solar cell containing Ag / Al core-shell composite nanoparticle light-trapping structure.

[0031] The matrix material described in step 1 is t...

Embodiment 1

[0035] Step 1: Select the surface of the thin film solar cell as the base material;

[0036] Step 2: Prepare an Ag thin film at room temperature by magnetron sputtering on the base material, and the thickness of the Ag thin film is 10nm;

[0037] Step 3: performing in-situ annealing on the Ag thin film, the annealing temperature is 450° C. to form Ag core nanoparticles;

[0038] Step 4: On the base material of the prepared Ag core nanoparticles, the Al film is prepared at room temperature by the magnetron sputtering method again, and the thickness of the Al film is 7nm;

[0039] Step 5: Perform in-situ annealing on the Al thin film, the annealing temperature is 250°C, and at the same time form the Al shell nanoparticles, form the Ag / Al core-shell composite nanoparticle light-trapping structure of the thin film solar cell;

[0040] Step 6: improve the solar cell device process, and prepare thin-film solar cells containing Ag / Al core-shell composite nanoparticle light-trapping ...

Embodiment 2

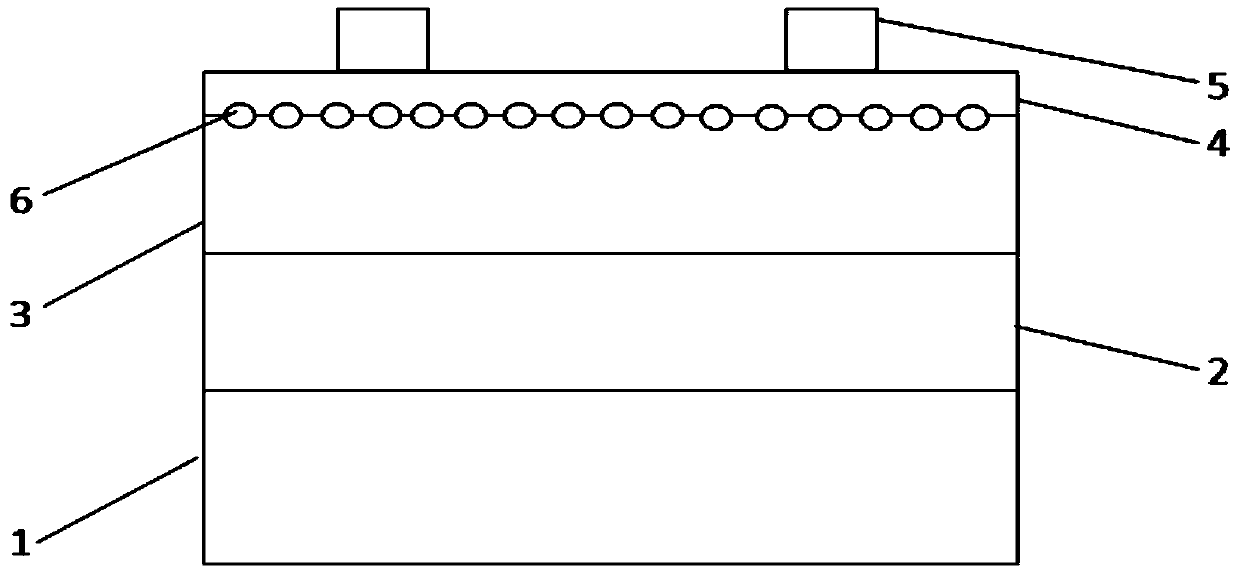

[0042] Step 1: Select a solar cell device without an anti-reflection film as the base material;

[0043] Step 2: Prepare an Ag thin film at room temperature by magnetron sputtering on the base material, and the thickness of the Ag thin film is 7nm;

[0044] Step 3: performing in-situ annealing on the Ag thin film at a temperature of 500°C to form Ag core nanoparticles;

[0045] Step 4: On the base material of the prepared Ag core nanoparticles, the Al film is prepared at room temperature by magnetron sputtering again, and the Al film is 8nm;

[0046] Step 5: Perform in-situ annealing on the Al thin film, the annealing temperature is 300°C, and at the same time form the Al shell nanoparticles, form the Ag / Al core-shell composite nanoparticle light-trapping structure of the thin film solar cell;

[0047] Step 6: Prepare an anti-reflection film, improve the solar cell device process, and prepare a thin-film solar cell containing Ag / Al core-shell composite nanoparticle light-trap...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com