Laminated sheet type bypass wave absorbing device and manufacturing method thereof

A manufacturing method and wave absorber technology, applied in impedance networks, electrical components, multi-terminal pair networks, etc., can solve the problems of difficulty in making larger, weakening effect, and small inductance, so as to suppress electromagnetic interference and improve anti-interference ability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

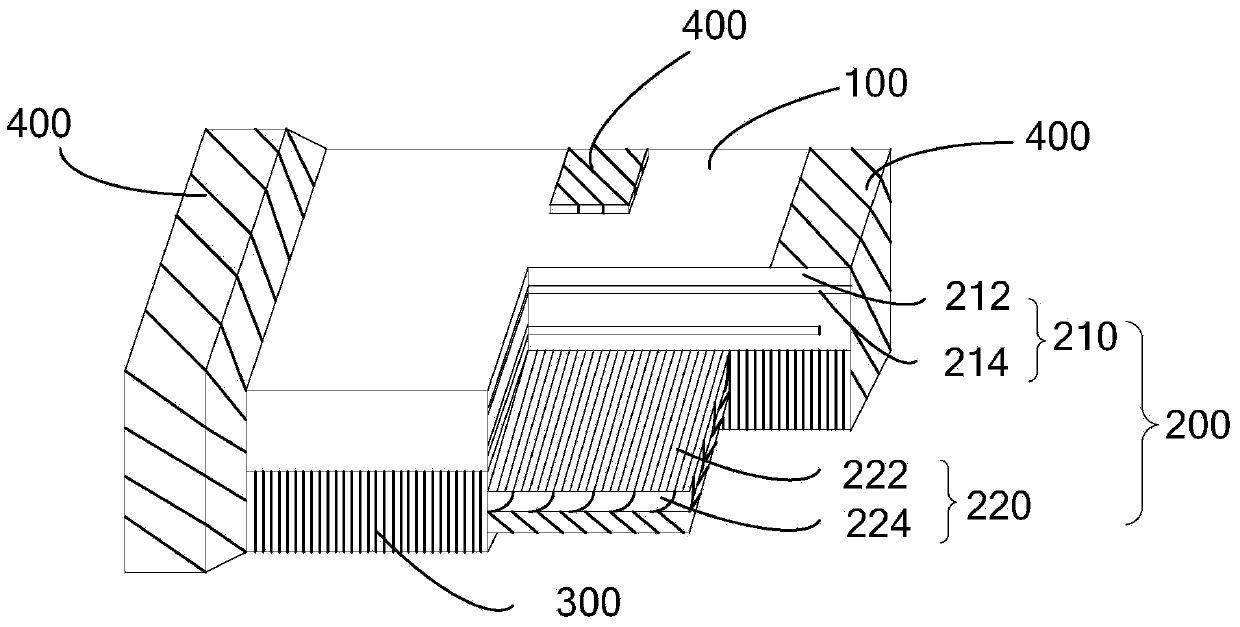

[0039] Such as figure 1 As shown, it is a sectional view of a laminated chip bypass absorber of an embodiment. The laminated chip bypass absorber includes a first cover 100 , an intermediate layer 200 and a second cover 300 . Wherein the first cover 100 is a dielectric ceramic material diaphragm, the middle layer 200 includes a chip capacitor unit 210 and a chip inductor functional device unit 220, and the chip capacitor unit 210 and the chip inductor unit 220 are laminated in parallel. The layers are integrated in a laminated chip monolith. The chip capacitor cell 210 includes a dielectric ceramic material diaphragm 212 and the internal electrode 214 printed on it, and correspondingly the chip inductor functional device cell 220 includes a ferrite material diaphragm 222 and the internal electrode 224 printed on it. , the second cover 300 is a ferrite material diaphragm.

[0040] It can be understood that the positions of the first cover 100 and the second cover 300 can be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com