Preparation method of liquid biological organic fertilizer

A bio-organic fertilizer and liquid technology, applied in fertilization devices, fertilizer mixtures, applications, etc., can solve problems such as troublesome ingredients, insufficient fertility, and slow nutrient supply, and achieve the effects of improving crop quality, less fertilization procedures, and improving soil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

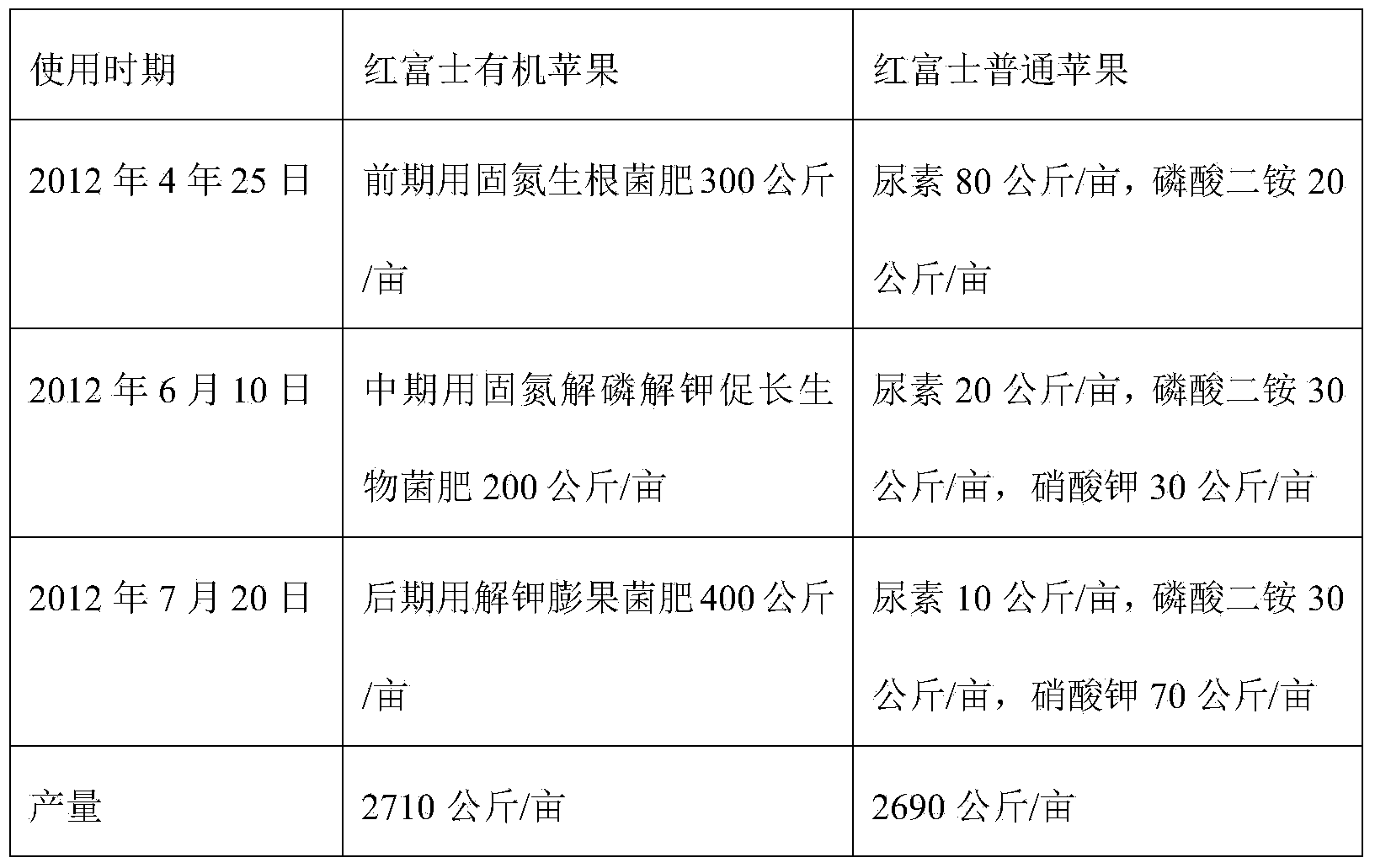

Examples

Embodiment 1

[0028] 1. Mix Pleurotus eryngii mushroom residue, phosphoric acid, manganese chloride and water according to the weight ratio of 80:50:5:600; obtain a reaction mixture; and stir and decompose the reaction mixture at 120°C to 150°C for 10 hours; Then the pH of the neutralization reaction mixture is 7.0, and the solid-liquid separation is carried out, and the separated liquid is the basic nutrient substance for producing liquid bio-organic fertilizer.

[0029] 2. Uniformly mixing the basic nutrients, supplementary nutrients and fermenting microorganisms to obtain a fermentation mixture.

[0030] Add the following substances to 1000 kg of basic nutrients:

[0031] Supplementary nutrients: 50 kg of wheat bran passed through a 3 mm sieve; 30 kg of rice bran passed through a 3 mm sieve; 20 kg of brown sugar; 2 kg of white sugar; 1 kg of glucose; 22% by weight, 5 kg; potassium ore powder with a fineness of less than 100 mesh, of which the content of potassium oxide is 12% by weight,...

Embodiment 2

[0035]1. Mix Pleurotus eryngii mushroom residue, phosphoric acid, manganese chloride and water according to the weight ratio of 200:200:25:800; obtain a reaction mixture; the reaction mixture is stirred and decomposed at 120°C to 150°C for 125 hours; Then, the pH of the neutralization reaction mixture is 6.6, and the solid-liquid separation is carried out, and the separated liquid is the basic nutrient substance for producing the liquid bio-organic fertilizer.

[0036] 2. Uniformly mixing the basic nutrients, supplementary nutrients and fermenting microorganisms to obtain a fermentation mixture.

[0037] Add the following substances to 1000 kg of basic nutrients:

[0038] Supplementary nutrients: 30 kg of wheat bran passed through a 3 mm sieve; 40 kg of rice bran passed through a 3 mm sieve; 10 kg of brown sugar; 8 kg of white sugar; 5 kg of glucose; 22% by weight, 205 kg; potassium ore powder with a fineness of less than 100 mesh, of which the content of potassium oxide is 1...

Embodiment 3

[0042] 1. Mix Pleurotus eryngii mushroom residue, phosphoric acid, manganese chloride and water in a weight ratio of 120:130:18:700; obtain a reaction mixture; stir and decompose the reaction mixture at 120°C to 150°C for 60 hours; Then the pH of the neutralization reaction mixture is 7.2, and the solid-liquid separation is carried out, and the separated liquid is the basic nutrient substance for producing the liquid bio-organic fertilizer.

[0043] 2. Uniformly mixing the basic nutrients, supplementary nutrients and fermenting microorganisms to obtain a fermentation mixture.

[0044] Add the following substances to 1000 kg of basic nutrients:

[0045] Supplementary nutrients: 25 kg of wheat bran passed through a 3 mm sieve; 35 kg of rice bran passed through a 3 mm sieve; 15 kg of brown sugar; 10 kg of white sugar; 5 kg of glucose; 22% by weight, 5 kg; potassium ore powder with a fineness of less than 100 mesh, of which the content of potassium oxide is 12% by weight, 30 kg; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com