Processing method of high-strength wear-resistant bucket lip of large excavator

A processing method and excavator technology, which is applied to mechanically driven excavators/dredgers, earth movers/shovels, construction, etc., can solve problems affecting the production order of domestic users, long cycle time, and high prices of imported bucket lips. problems, achieve the effect of shortening the lead time, shortening the manufacturing time, and reducing the procurement cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Composition design of bucket lip:

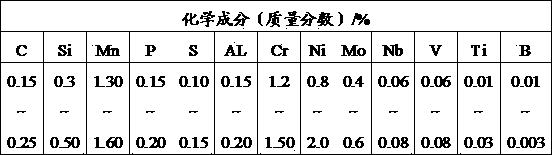

[0028] Table 1 Additive components of test steel used in manufacturing bucket lip

[0029]

[0030] Prepare steelmaking materials according to the design composition in Table 1, and use a 50T electric furnace for smelting to ensure that the chemical composition and trace elements of the material are consistent with the design composition. The smelting temperature is controlled at 1580°C±10°C, oxygen is blown, and the temperature is kept for 8 hours. The billet weighed 48.7 tons.

[0031] Vacuum electroslag furnace is used for secondary smelting to reduce harmful components such as S and P, and remove impurity layers at both ends. After electroslag smelting, the size is φ1580mm×2500mm, and the actual weight is 38.47 tons.

[0032] A 2,000-ton hydraulic press is used for blanking, and the length, width, and height dimensions after blanking are 8100 mm×2600 mm×230 mm. After further heating and forging, the final billet size is 268...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com