Antistatic composite fiber precursor, antistatic processed yarn prepared therefrom, and manufacturing method therefor

A composite fiber and manufacturing method technology, applied in the field of antistatic composite fiber precursor and antistatic processed yarn, can solve the problems of poor antistatic durability, inability to increase the fluffy feeling of curling, limited clothing and application scope, etc. Soft hand feel, heat retention, increase practical value, and improve the effect of application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific example 1

[0046] The relationship between the content ratio of conductive composite polymer substrate and the physical properties of antistatic composite fiber precursor

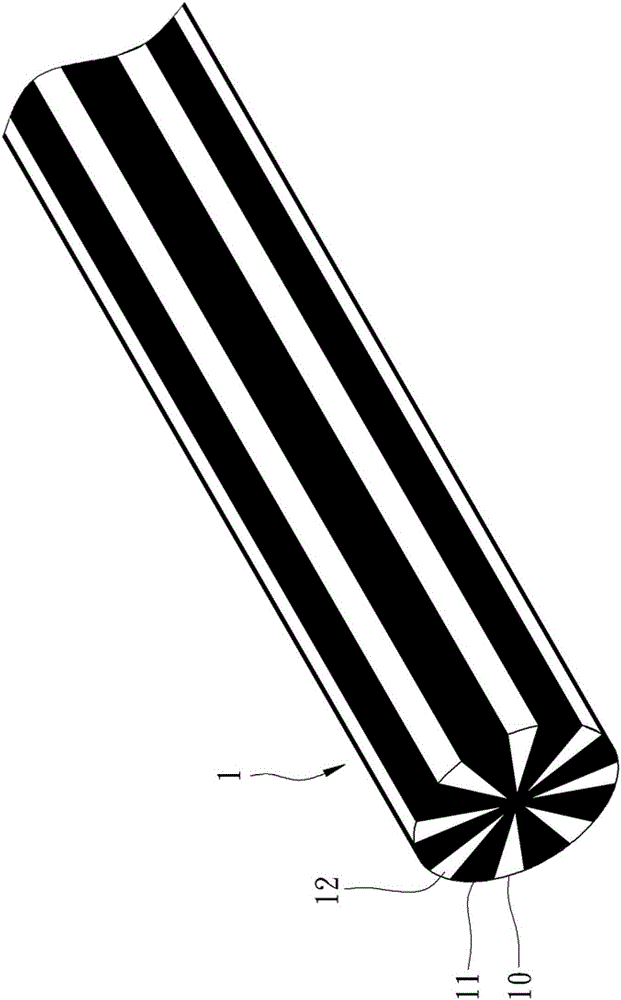

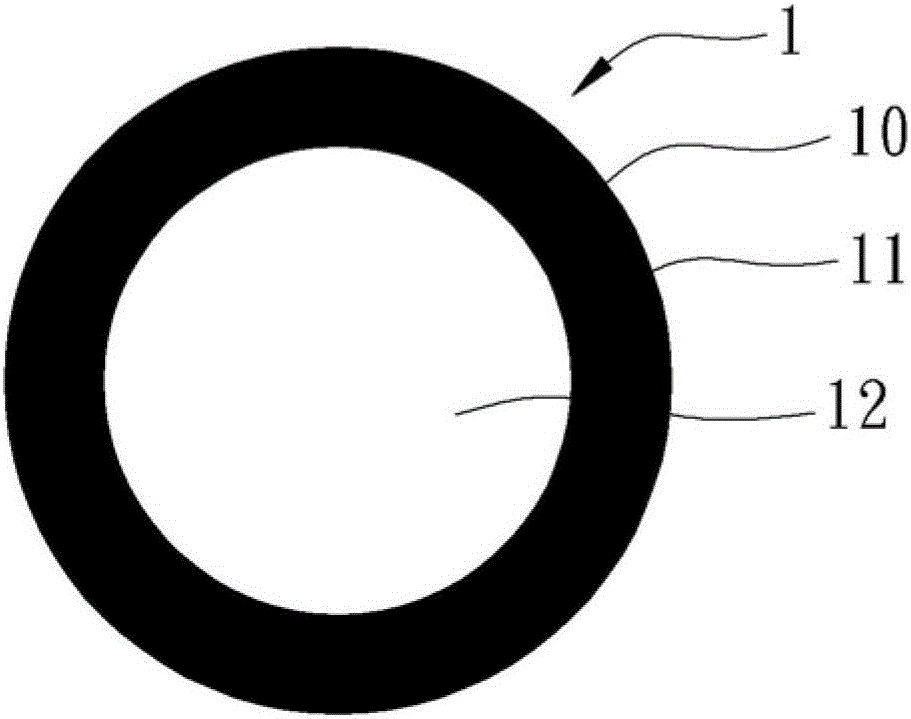

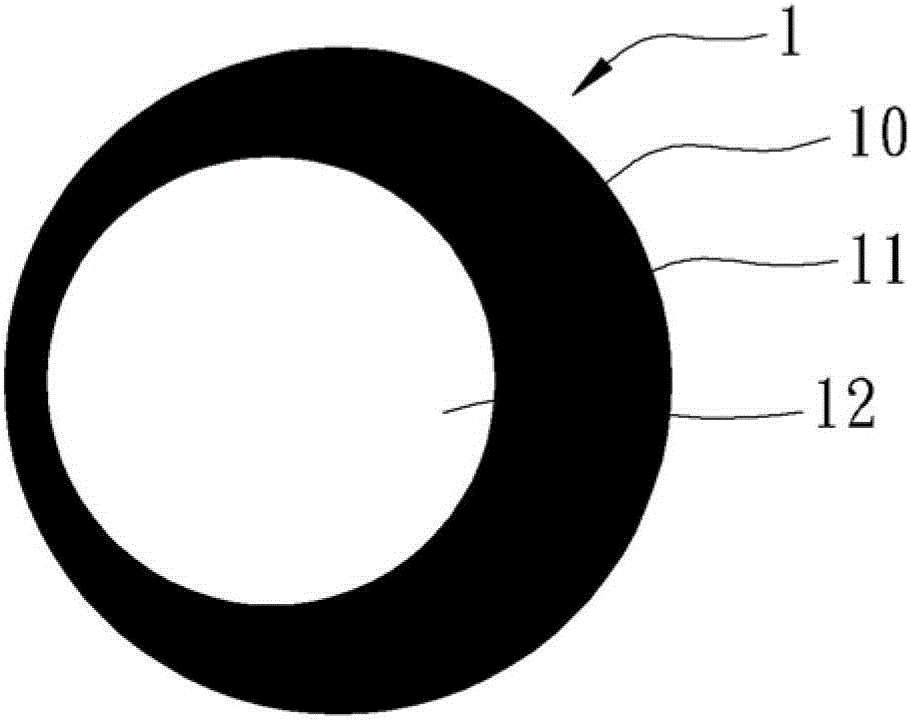

[0047] A conductive composite polymer substrate containing 15±0.5wt% conductive carbon black and polybutyleneterephthalate (PBT for short), and polyethylene terephthalate (PET for short) ) fiber polymer base material, extruded to the same spinning hole at the same time for composite spinning, and made with such Figure 2e The cross-section type of antistatic composite fiber precursor. Among them, by changing the volume ratio of the conductive composite polymer substrate in the antistatic composite fiber precursors, the A1-A8 antistatic composite fiber precursor samples shown in Table-1 were respectively prepared, and the samples were prepared according to the requirements of TAQ2000. Test Standards Measure the glass transition temperature (Tg) of the aforementioned 8 samples, measure the ultimate strength and elonga...

specific example 5

[0085] Changes in surface resistance of antistatic composite fiber precursors made into antistatic processed yarns

[0086] Antistatic composite fiber precursor samples C1~C5 with different surface resistances were prepared respectively. After the aforementioned precursor samples were subjected to false twist processing with the processing parameters in Example 5 in Table-4 to make antistatic processed yarns, they were then respectively The surface resistance of the processed wire was measured, and the results are shown in Table-6.

[0087] The cross-sectional types of samples C1~C5 are all adopted such as Figure 2e In the type shown, the polymer materials used in the conductive composite polymer substrates of samples C1~C5 are all PBT, and the polymer materials in the fiber polymer substrates are all PET. In addition, the conductive carbon black content in the conductive composite polymer base material of the aforementioned samples, and the proportion of the conductive com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com