Construction method for flexible composite impermeable layer of upstream face of high arch dam

A composite anti-seepage and construction method technology, applied in the direction of arch dams, dams, water conservancy projects, etc., can solve the problems of destroying the integrity of the dam concrete, affecting the normal operation of the dam, and cracks in the foundation, so as to reduce the pressure of high-pressure hydraulic splitting. The risk of cracking, the construction quality is easy to control, and the effect of improving the overall impermeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

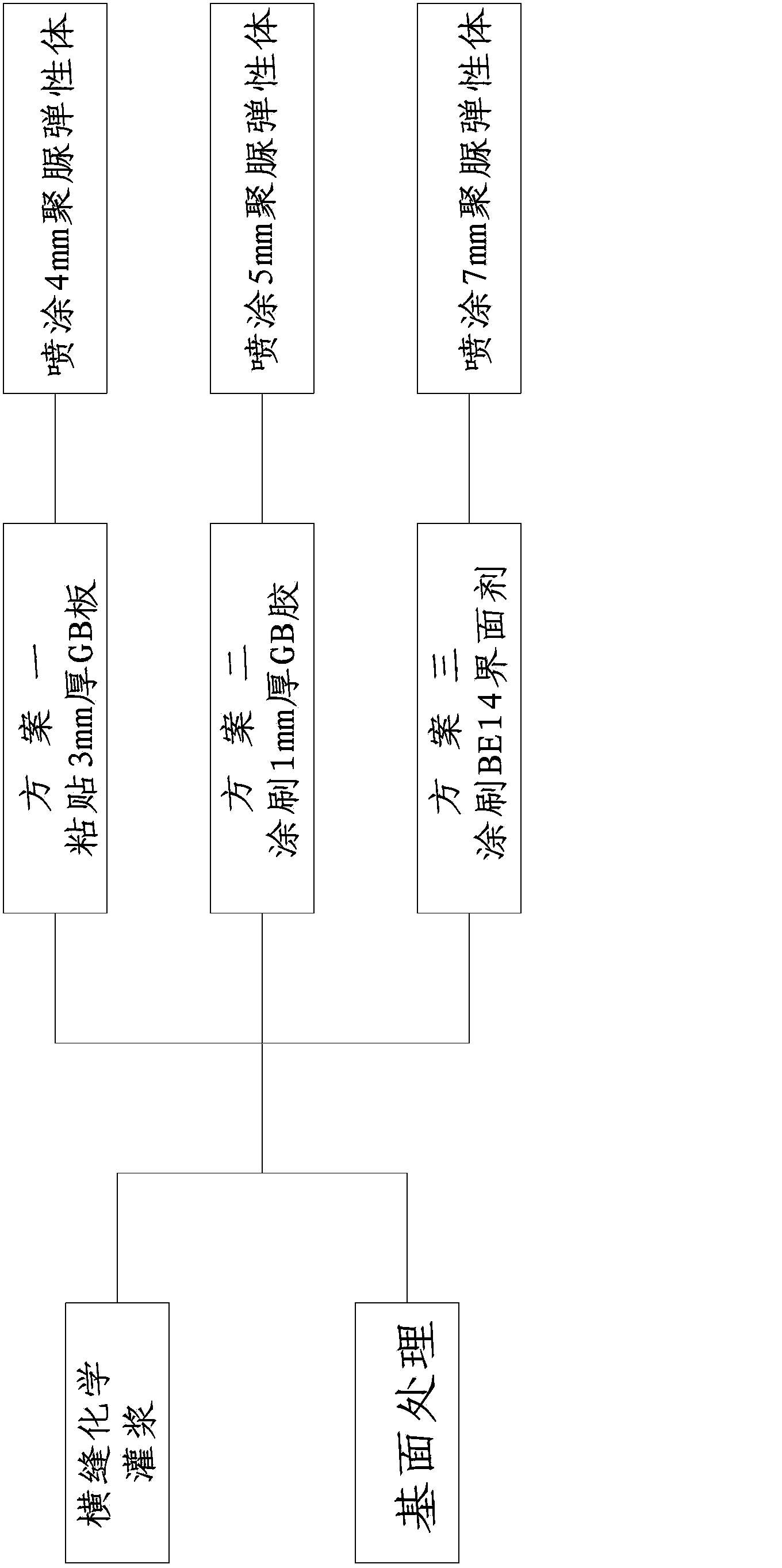

[0025] A construction method for a flexible composite anti-seepage layer on the upstream face of a high arch dam, such as figure 1 Shown is the construction process flow chart of the composite anti-seepage layer, and the construction method includes the following steps:

[0026] 1. Base surface treatment: first, use an angle grinder to grind the concrete surface, then use a high-pressure water gun to wash the surface dust, scum and surface dirt, and finally, after the water evaporates, use caulking materials for larger holes leveling;

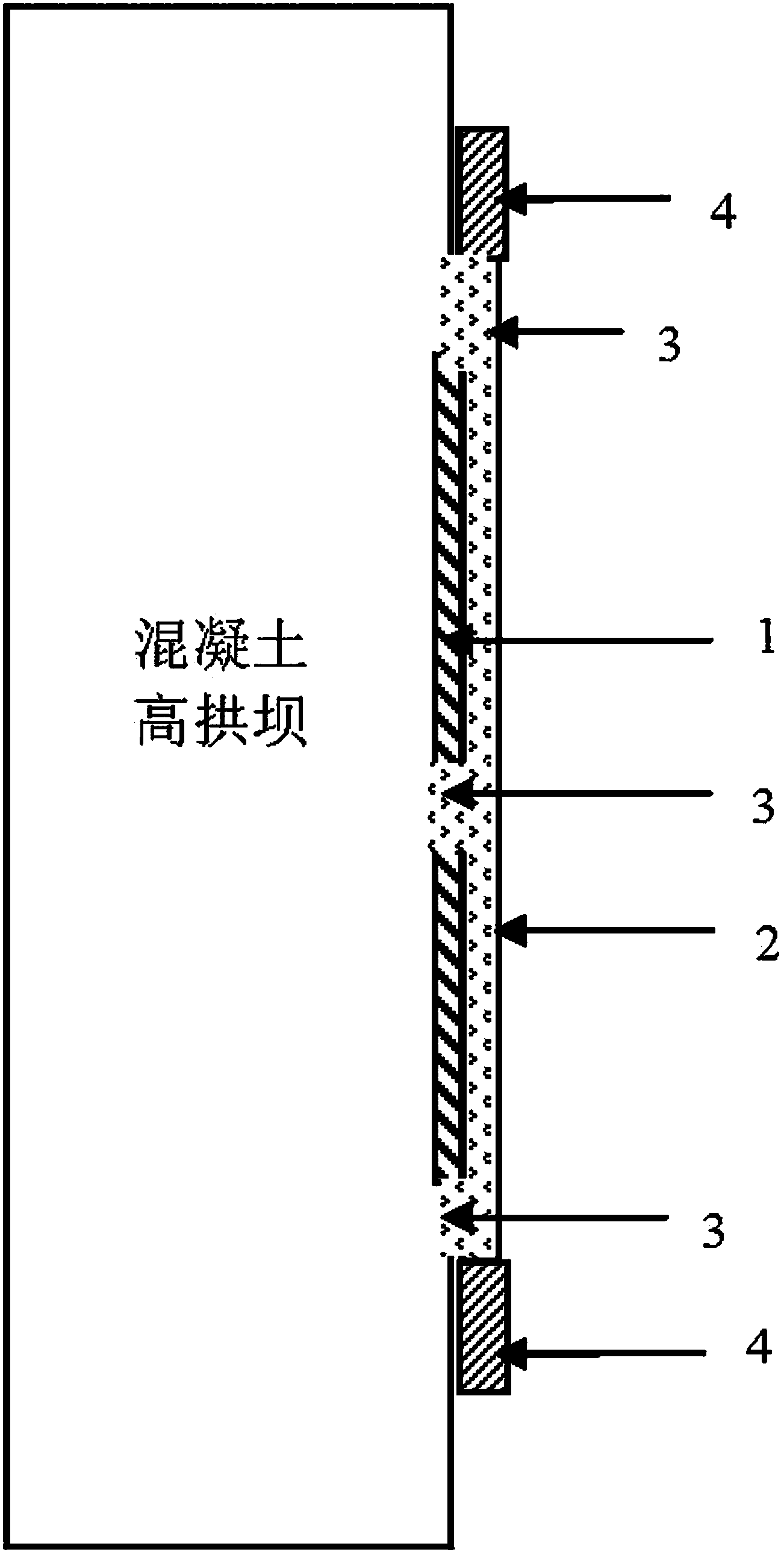

[0027] 2. Paste the GB sealing plate as the inner protective layer of the flexible composite anti-seepage layer. The specific steps are: after the concrete bottom surface is treated, apply GB glue on the flat and dirt-free concrete surface, and then paste the GB sealing plate;

[0028] 3. Brushing GB glue as the inner protective layer of the flexible composite anti-seepage layer. The specific steps are: after the concrete bottom surface is tre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com