Device and method for improving operating efficiency of air compressor by utilizing air pressure waste heat

An operating efficiency, air compressor technology, applied in pump devices, mechanical equipment, machines/engines, etc., can solve the problems of inability to fully utilize or not utilize in summer, affecting the utilization efficiency of waste heat, etc., to reduce operation and maintenance costs, improve Effects on Gas Quality and Efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

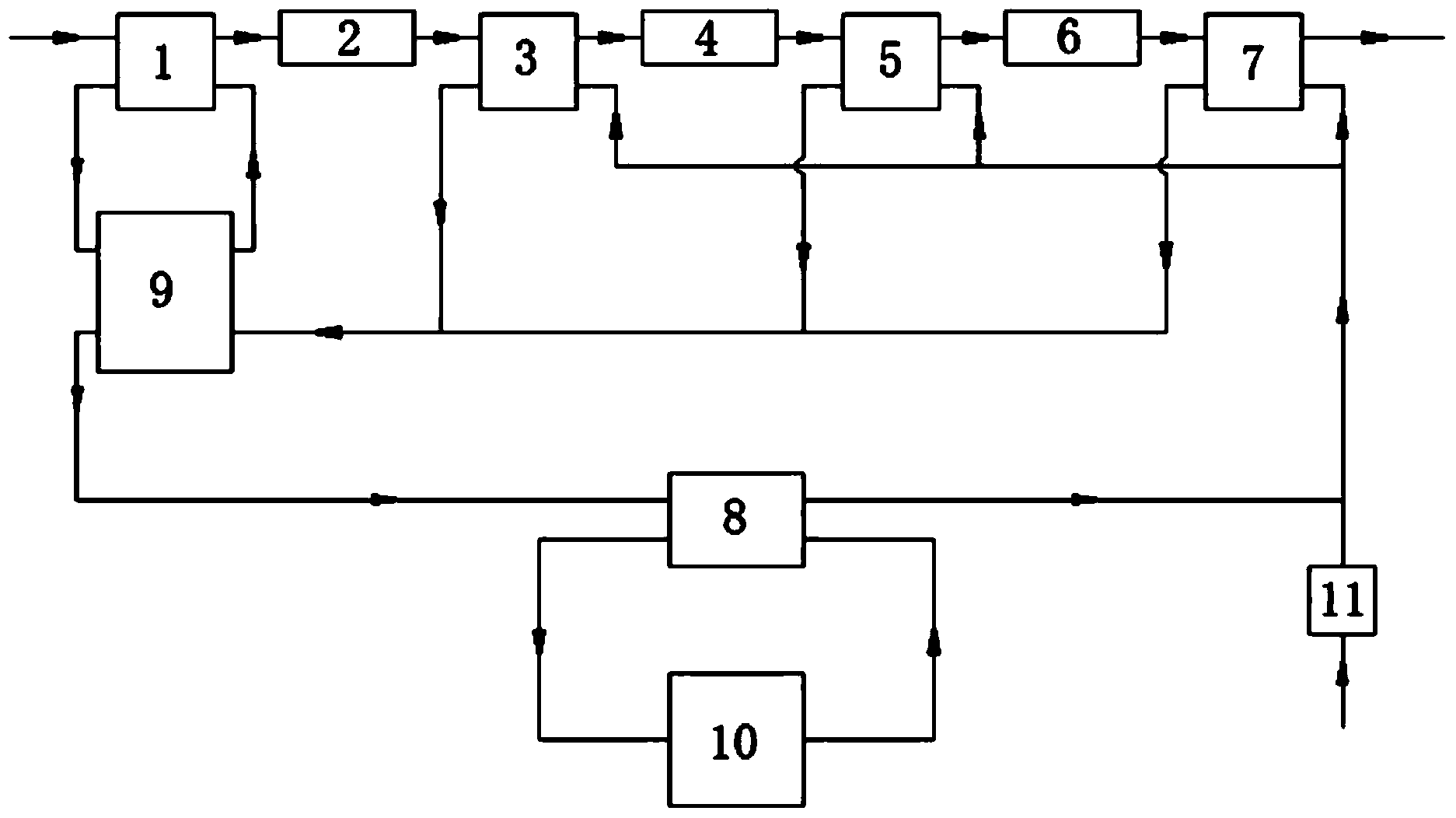

[0034] The present invention will be further explained in detail below in conjunction with the accompanying drawings of the description.

[0035] The device for improving the operating efficiency of the air compressor by using the waste heat of the air compressor includes three-stage compressors: air cooler 1 and first-stage compressor 2, first-stage cooler 3, second-stage compressor 4, second-stage cooler 5, and third-stage compressor The machine 6 and the third-stage cooler 7 are connected in sequence, the air is introduced from the air cooler 1, and the compressed air is output from the third-stage cooler 7; the air cooler 1 and the absorption refrigeration unit 9 are connected by pipelines to form a chilled water circulation loop; Type refrigerating unit 9 is connected to heat exchanger 8 through pipelines, and heat exchanger 8 is respectively connected to primary cooler 3, secondary cooler 5 and tertiary cooler 7 through pipelines, primary cooler 3, secondary cooler 5 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com