Constant-pressure air supply valve terminal system

A valve island and voltage stabilization technology, which is applied in fluid pressure actuators, servo motor components, mechanical equipment, etc., can solve problems such as reducing the service life of actuators or their peripheral components, unstable recovery actions, and unfavorable production needs. Achieve the effect of saving installation space, simple structure and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

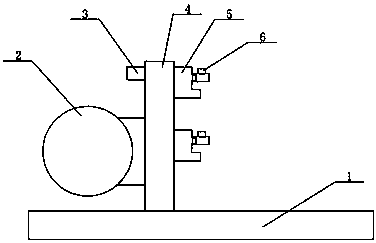

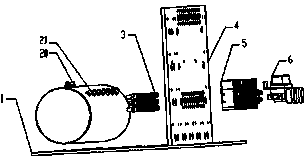

[0024] refer to Figure 1 to Figure 3

[0025] The working principle of the present invention: when the compressed air from the factory is directly passed to the centralized air supply tank 2, the centralized air supply tank 2 can store 8.5L of compressed air at a corresponding pressure, which is equivalent to supplying each pressure regulating valve 6 to the nearest Equipped with an air compressor with a volume of 8.5L, so that each pressure regulating valve 6 will have sufficient air supply, and the output pressure fluctuation during the production process can be ignored, and the compressed air regulated by the pressure regulating valve 6 is then separately Output to the air inlets on one or more valve islands. These air inlets correspond to their unique solenoid valves 5. Based on the previous preparations for voltage stabilization, the pressure of the compressed air received by each solenoid valve 5 is very high. Stable, and the action of the pneumatic actuator driven by ...

Embodiment 2

[0031] refer to Figure 1 to Figure 3

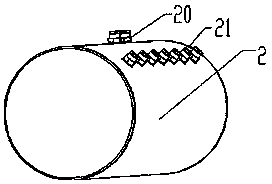

[0032] A stabilized air supply valve island system, which includes a base support plate 1, a centralized air supply tank 2, an air joint 3, a valve island motherboard 4, a solenoid valve 5, and a pressure regulating valve 6, characterized in that: the base supports The board 1 is fixedly connected to the bottom of the valve island motherboard 4 and the centralized air supply tank 2 directly below the valve island motherboard 4, and the centralized air supply tank 2 is provided with one or more ports for connecting compressed air. Air intake hole 20 and a plurality of air outlet holes 21, the valve island motherboard 4 is provided with a plurality of independent air inlets and air outlets, and each air outlet hole 21 of the centralized air supply tank 2 is connected with the gas joint 3 The corresponding pressure regulating valve 6 on the valve island motherboard 4 is connected to the air inlet, and the pressure regulating valve 6 is con...

Embodiment 3

[0035] refer to Figure 1 to Figure 3

[0036] The factory compressed air is first connected to the Φ12 air intake hole 20 on the centralized air supply tank 2, and then connected to a pressure regulator through the 8 Φ8 air outlet holes 21 on the centralized air supply tank 2. After the pressure is adjusted by the pressure regulating valve, Then the air outlet 21 is connected to each electromagnetic valve 5, and finally the compressed air is transmitted to the actuator through the opening and closing of the electromagnetic valve 5, so as to complete the corresponding mechanical action requirements.

[0037] The user can freely configure the number of pressure regulating valves 6, the number of solenoid valves 5, and the ratio of pressure regulating valves 5 and solenoid valves 6 according to the number of actions and the relationship between them.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com