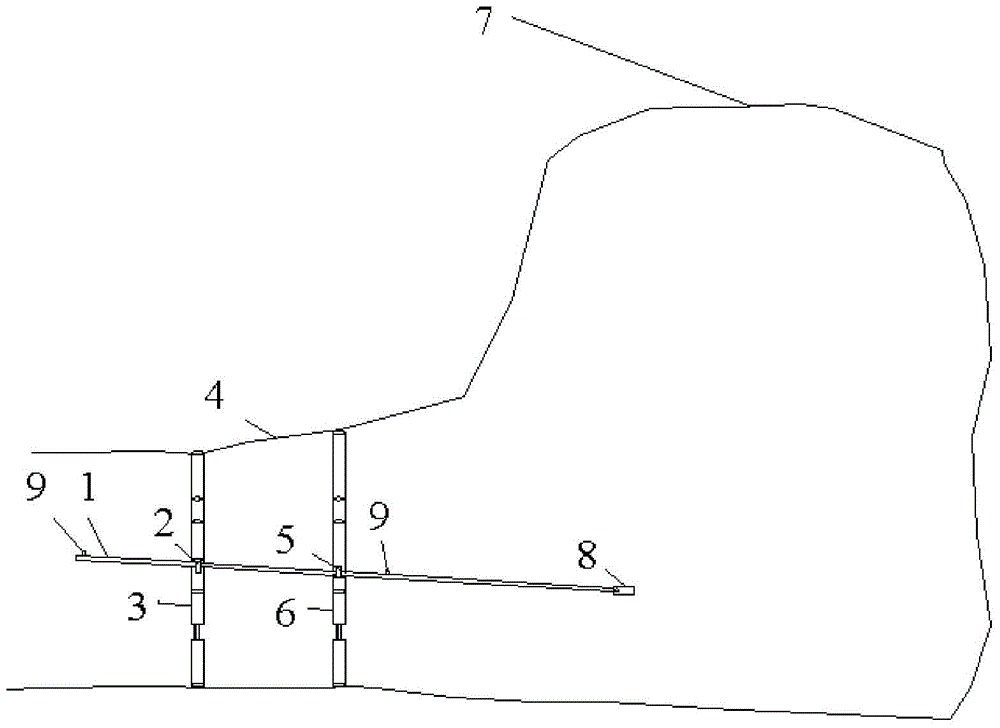

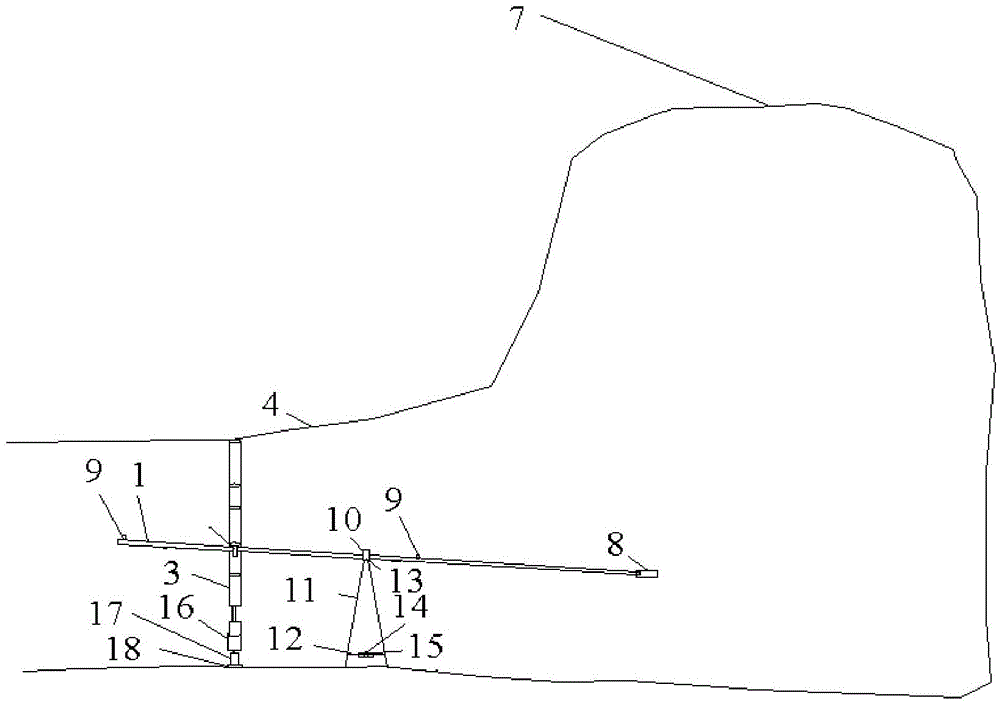

Auxiliary measurement system of CMS detector

An auxiliary system and detector technology, applied in the direction of measuring devices, measuring instruments, measuring point markings, etc., can solve the problems of inability to rotate freely, normal production influence, and large space occupation, so as to reduce safety hazards, avoid bending deformation, avoid The effect of equipment damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] The crossbar (1) in this embodiment is made of high-strength carbon fiber tubes, the overlapping length of the expansion joints is 110 mm, the number of joints is 5, the length of a single joint is 2000 mm, and the total length is 9560 mm, namely (5*2000-4*110 ) mm, the maximum outer diameter of a single section is 200mm, and the minimum outer diameter is 60mm.

[0050] The overall height of the front bracket is 2m; the U-shaped groove (10) has a groove width of 214mm, and the arc groove (24) adopts a semicircular steel groove (that is, the steel pipe is cut in half along the axial direction, and the arc is 180°), with an outer diameter of Φ40mm; The anti-slip layer (13) covered on the outer surface of the semicircular steel channel is made of anti-slip rubber skin with stripes on the surface; the pillars of the tripod and the support beams between the pillars are made of white steel pipes, the outer diameter of the white steel pipes is Φ10mm, and the wall thickness 2mm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com