Negative electrode diachylon used for high-performance AGM battery and preparing method thereof

A negative electrode paste, high-performance technology, applied in the direction of battery electrodes, circuits, electrical components, etc., can solve the problems of poor charge acceptance performance, poor dynamic charge acceptance performance, prone to sulfation of the negative plate, and difficulty in meeting the requirements of starting and stopping. Achieve the effect of comprehensive performance improvement, excellent charging acceptance performance, and improvement of dynamic acceptance characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

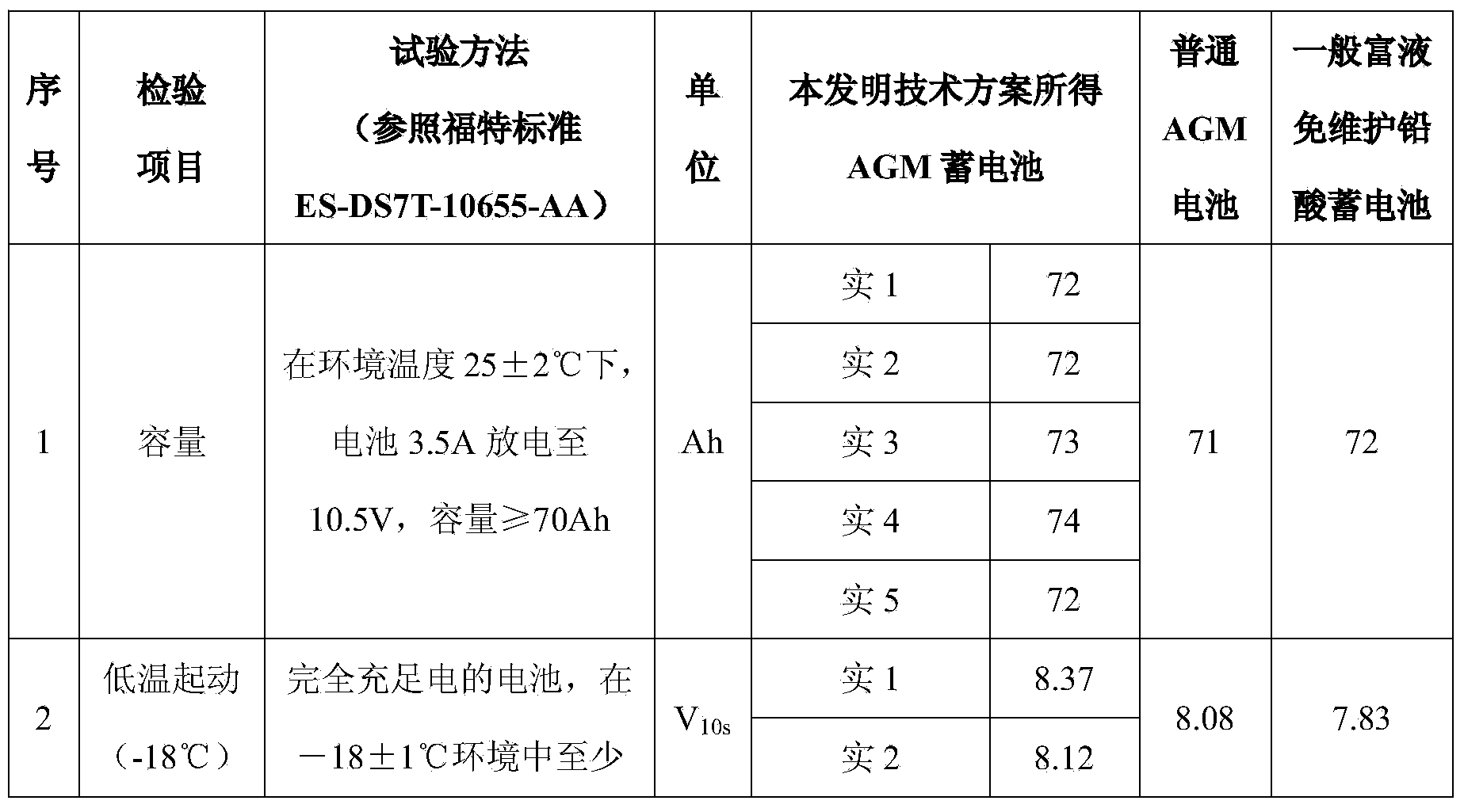

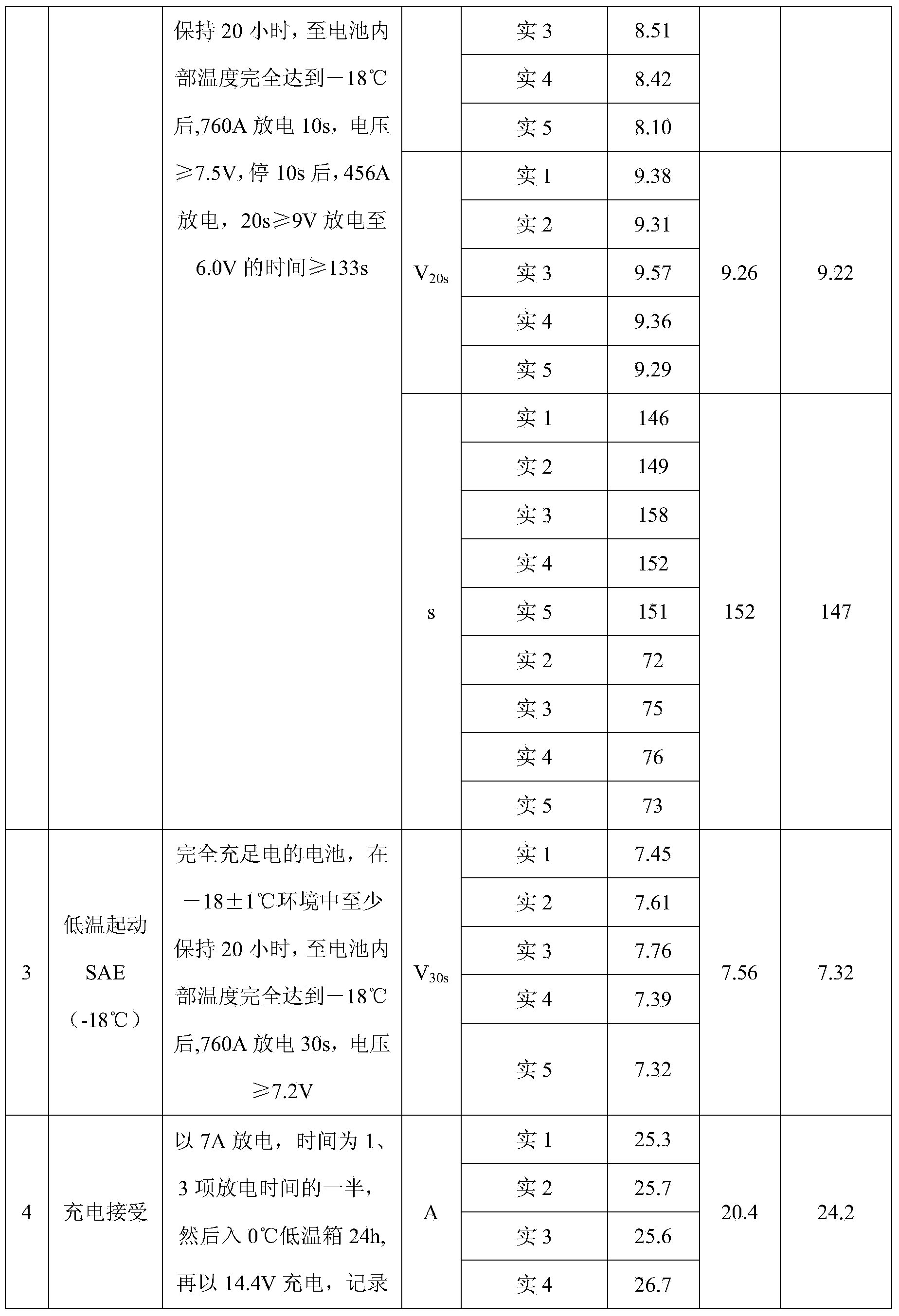

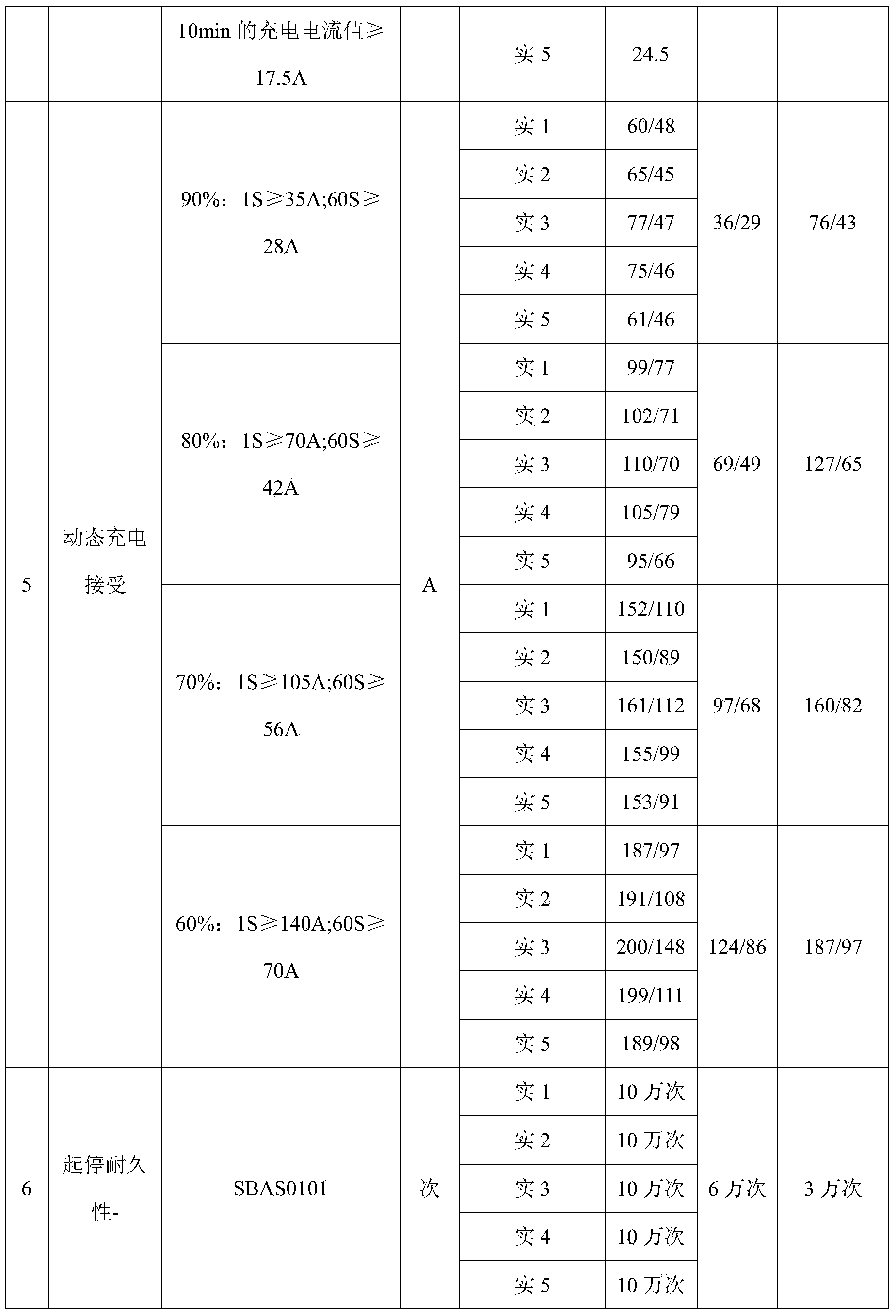

Examples

Embodiment 1

[0033] Add 100kg of lead powder (with a mass fraction of 75% PbO) into the paste mixing machine. Add 0.1kg medium and high specific surface area carbon black, 0.3kg low specific surface area conductive carbon black, 0.5kg ultrafine barium sulfate, 0.1kg sodium lignosulfonate, 0.5kg humic acid into the water mixing tank, and then add 10kg of purified Water, stirred at high speed and mixed evenly, poured into the pasting machine, after wet mixing with lead powder, quickly drenched with a density of 1.400g / cm 3 (25°C) sulfuric acid 9kg, control the temperature of the paste at 60°C during the paste mixing process, stir evenly, cool down to 40°C, and get the negative electrode lead paste after the paste is produced.

Embodiment 2

[0035] Add 90kg of lead powder (with a mass fraction of 75% PbO) into the pasting machine. Add 1kg medium and high specific surface area carbon black, 0.2kg low specific surface area conductive carbon black, 0.3kg ultrafine barium sulfate, 0.1kg sodium lignosulfonate, 0.1kg humic acid into the water mixing tank, and then add 10kg of purified water , high-speed stirring and mixing evenly, pour into the paste machine, wet mix with lead powder evenly, and quickly drench with a density of 1.42g / cm 3 (25°C) sulfuric acid 3kg, control the temperature of the paste at 60°C during the paste mixing process, stir evenly, cool down to 40°C, and the paste is produced to obtain the negative electrode lead paste.

Embodiment 3

[0037]Add 100kg of lead powder (with a mass fraction of 80% PbO) into the paste mixing machine. Add 0.8kg of medium and high specific surface area carbon black, 1kg of low specific surface area conductive carbon black, 0.5kg of ultrafine barium sulfate, 2kg of sodium lignosulfonate, and 0.2kg of humic acid into the water mixing tank, and then add 15kg of purified water, Stir at high speed and mix evenly, pour it into the paste machine, wet mix it with lead powder evenly, and pour it quickly with a density of 1.42g / cm 3 (25°C) sulfuric acid 7kg, control the temperature of the paste at 50°C during the paste mixing process, stir evenly, cool down to 30°C, and get the negative electrode lead paste after the paste is produced.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com