Multi-layer circuit board and manufacturing method thereof

A technology of a multilayer circuit board and a manufacturing method, which is applied in the direction of multilayer circuit manufacturing, printed circuit components, etc., can solve the problems of reducing circuit design area, affecting the yield and quality of circuit boards, and large thickness of embedded circuit boards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

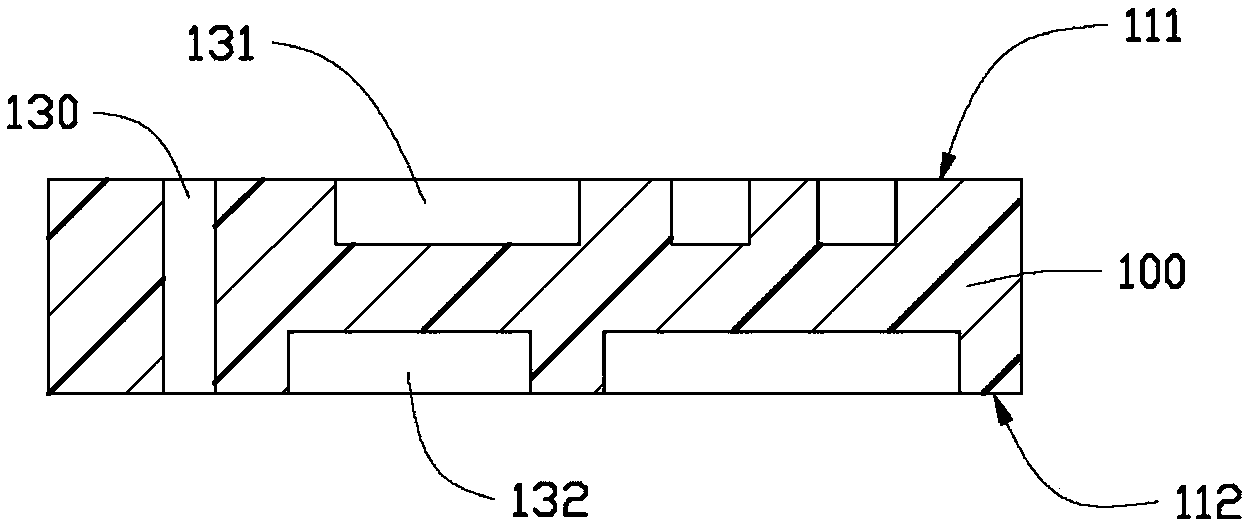

[0033] The multilayer circuit board provided by the technical solution and its manufacturing method will be further described in detail below in conjunction with the drawings and multiple embodiments.

[0034] The method for manufacturing a multilayer circuit board provided by the first embodiment of the technical solution includes steps:

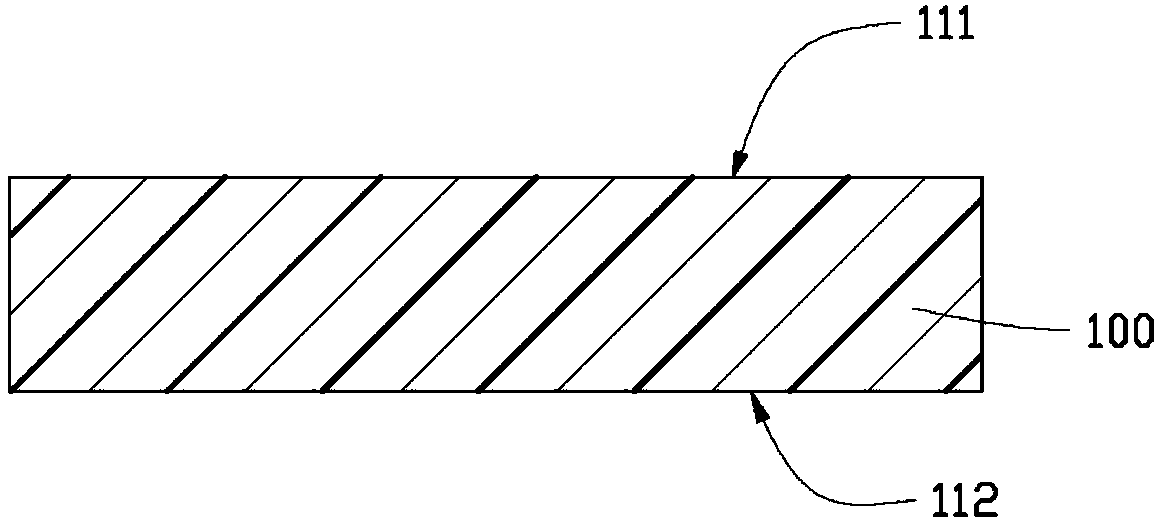

[0035] For the first step, please also refer to figure 1 and figure 2 , an insulating substrate 100 is provided, and the insulating substrate 100 has a first surface 111 and a second surface 112 opposite to each other.

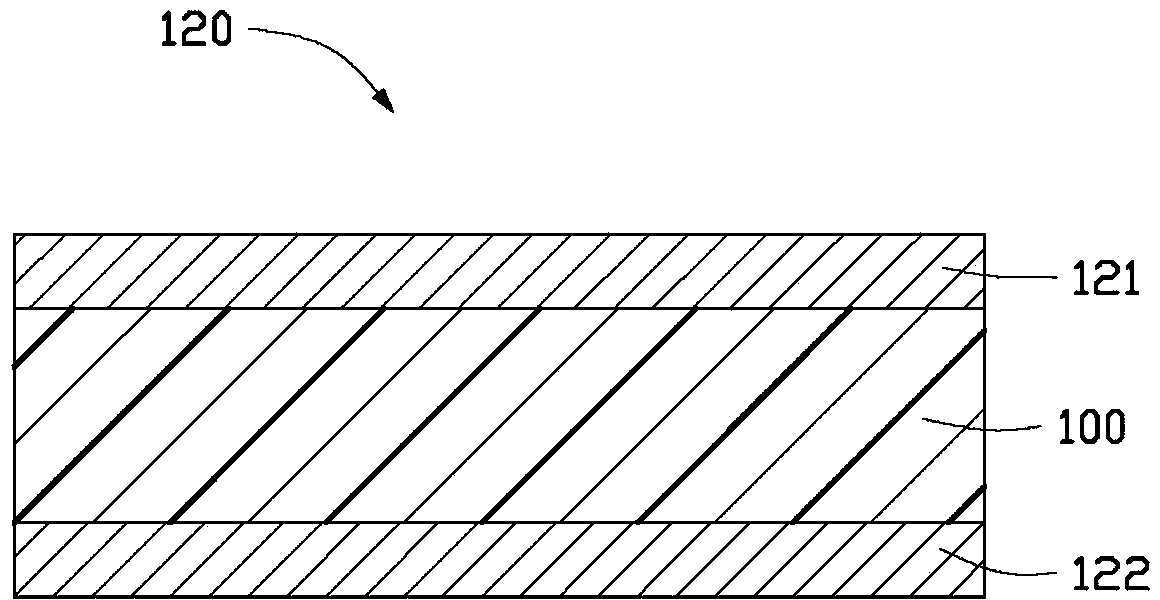

[0036] The insulating base 100 may be a purchased insulating sheet, or may be made by etching a purchased copper-clad substrate. In this embodiment, the insulating base 100 is formed through the following steps: First, a double-sided copper-clad substrate 120 is provided, and the double-sided copper-clad substrate 120 includes the insulating base 100 and the The upper copper foil 121 and the lower copper foil 122 ; seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com