Sintered cubic boron nitride tool

一种立方氮化硼、烧结体的技术,应用在制造工具、气态化学镀覆、金属加工设备等方向,能够解决脱落等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

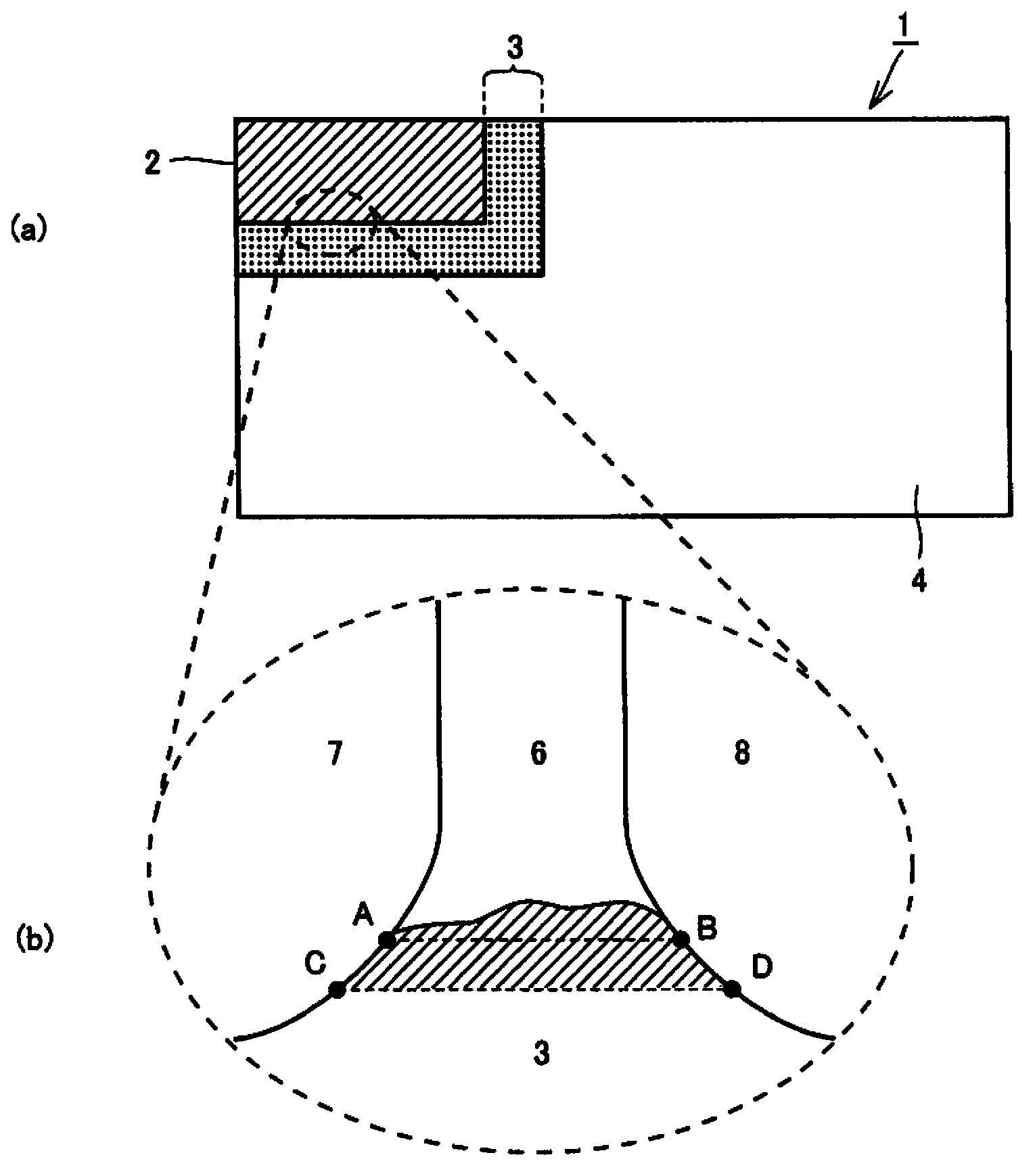

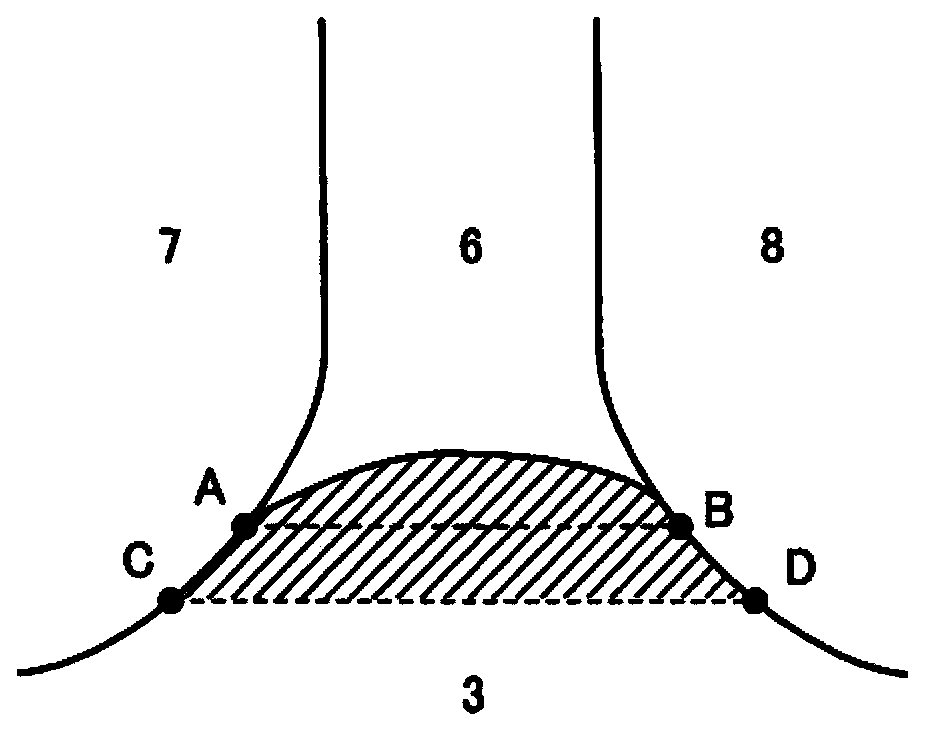

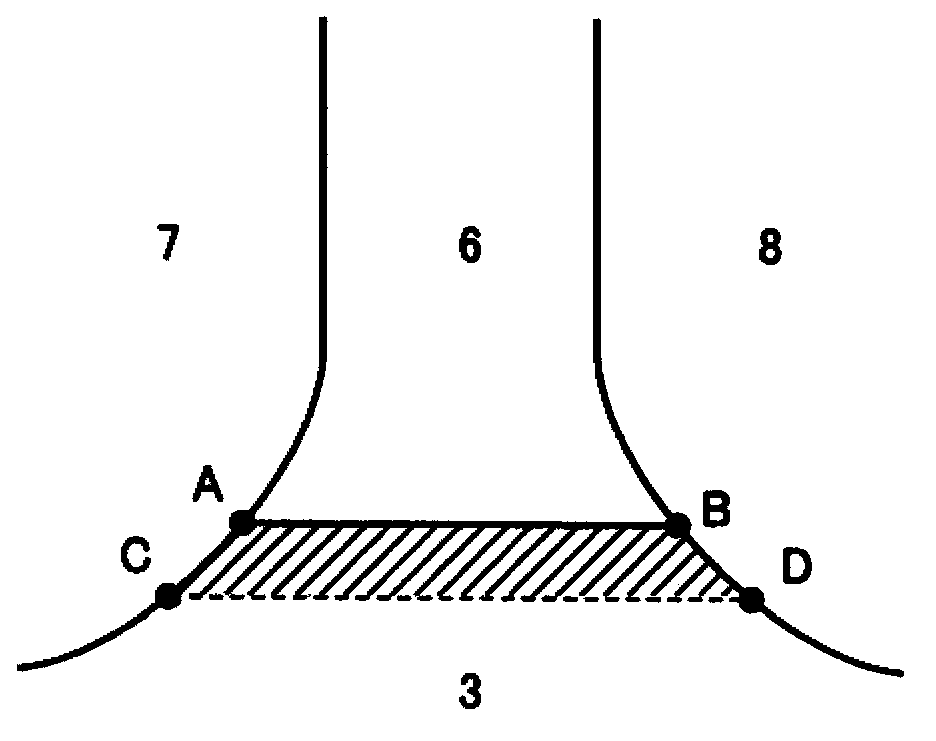

Image

Examples

Embodiment 1

[0100] A cBN sintered body tool was fabricated in the following manner. First, TiN powder with an average particle size of 20 μm is mixed with Al powder with an average particle size of 20 μm at a mass ratio of TiN:Al=4:1. Then, the mixture was heat-treated at 1250° C. for 30 minutes in vacuum. The mixture obtained by the heat treatment was pulverized with pellets made of cemented carbide having a diameter of Φ4 mm and a crucible made of cemented carbide. In this way, the raw material powder constituting the binder phase is obtained.

[0101] Then, the obtained raw material powder constituting the binder phase was mixed with cBN particles having an average particle diameter of 4 μm to obtain a cBN content of 72% by volume. The mixture thus obtained was placed in a vacuum furnace, and the temperature therein was raised to 950°C. Then, the mixture was kept there for 30 minutes to degas the powders.

[0102] Next, the degassed powders were layered on a support plate made of c...

Embodiment 2-7 and comparative example 1-6

[0107] The same method as in Example 1 was used to manufacture the cBN sintered body tools of Examples 2-7 and Comparative Examples 1-6, the difference being that by changing the immersion time of the cBN sintered body in the mixed solution, as shown in Table 1 " The surface of the cBN sintered body of the cBN sintered body tool of Example 1 was changed as shown in the column "Concavity Coefficient".

[0108]

Embodiment 8-9 and comparative example 7

[0110] The cBN sintered body tools of Examples 8-9 and Comparative Example 7 were manufactured in the same manner as in Example 3, except that the cBN sintering of Example 3 was changed as shown in the column "Materials Constituting the Bonding Layer" of Table 1. The material that makes up the bonding layer in the bulk tool.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resonant frequency | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com