Self-contained emergency spent nuclear fuel pool cooling system

一种废核燃料、冷却剂的技术,应用在冷却装置、反应堆、核工程等方向

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

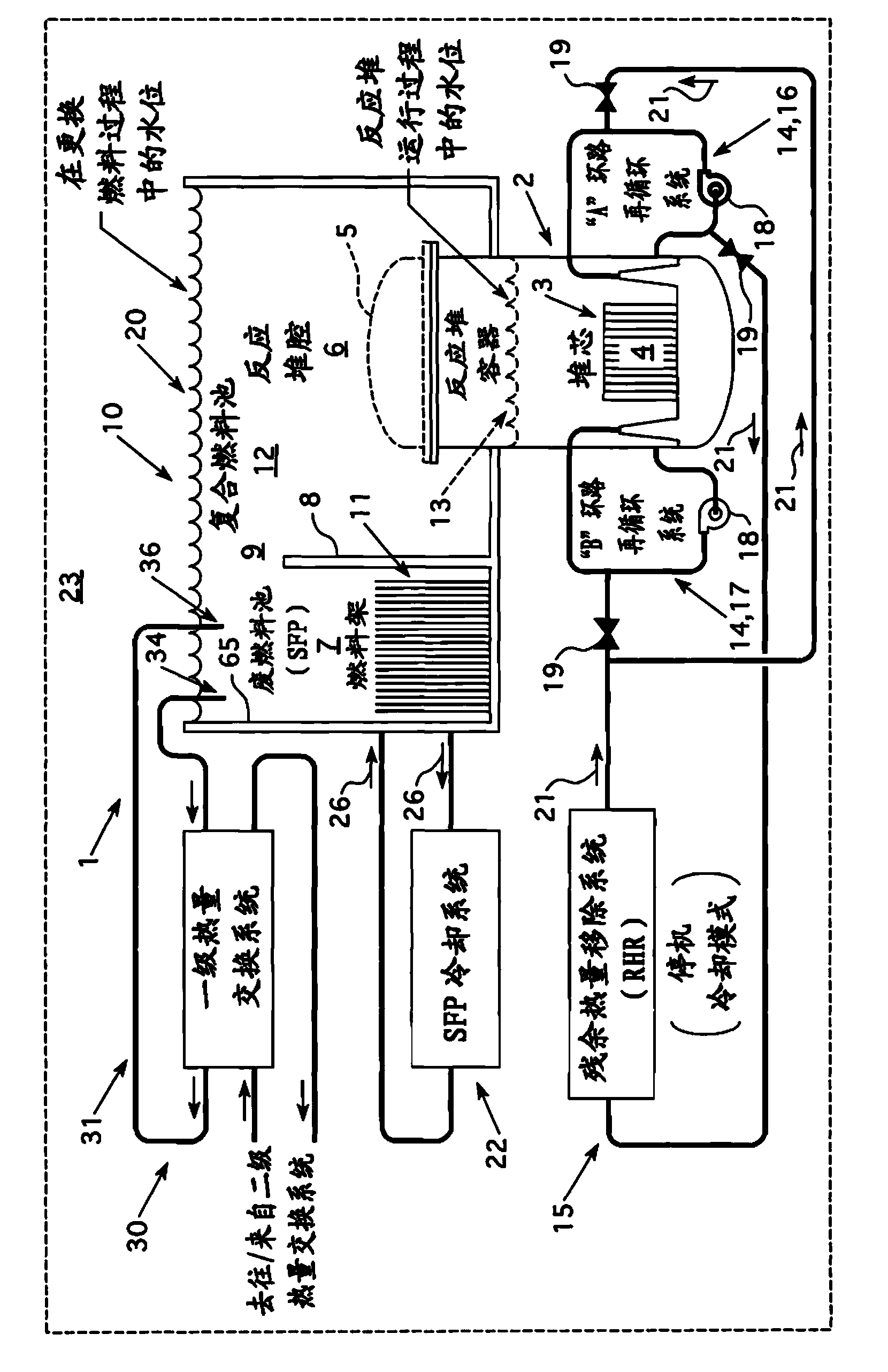

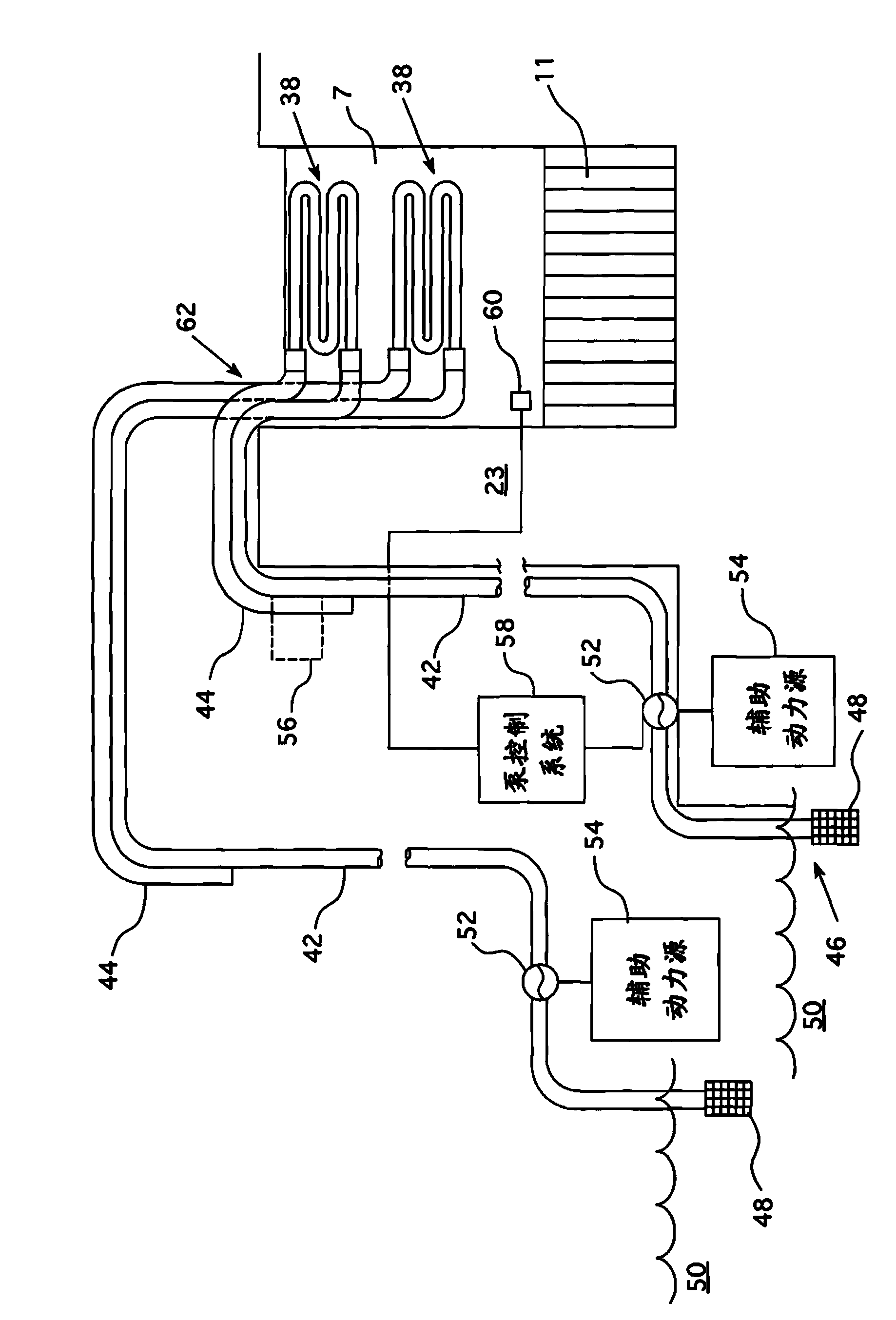

[0015] As shown in FIG. 1 , in a typical light water reactor nuclear power generation facility (only its relevant components are shown), a reactor building 23 contains a reactor vessel 2 that contains a core 3 that Comprising a plurality of nuclear fuel elements 4, usually in the form of fuel bundles, generally referred to as fuel assemblies. During power generating operation, the reactor vessel 2 is closed by a roof or canopy 5 . The reactor vessel 2 is positioned within a reactor cavity 6 which in some designs is fluidly connected to a spent fuel pool 7 during an outage. However, even in designs where the reactor cavity is connected to the spent fuel pool during an outage, containment isolation during operation requires separation of the spent fuel pool water from the water in the replacement fuel cavity and the reactor cavity. In the embodiment of the facility shown in Figure 1, the spent fuel pool 7 is separated from the reactor chamber by a wall 8 having a closable openi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com