Method for preparing paper-making-method reconstituted tobacco with sun-cured red tobacco style characteristic

A technology for reconstituted tobacco leaves and sun-cured red tobacco, which is applied in the preparation of tobacco, tobacco, and applications. It can solve problems such as no public reports, and achieve the effects of simple and easy methods, improved aroma quality, and enhanced aroma quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

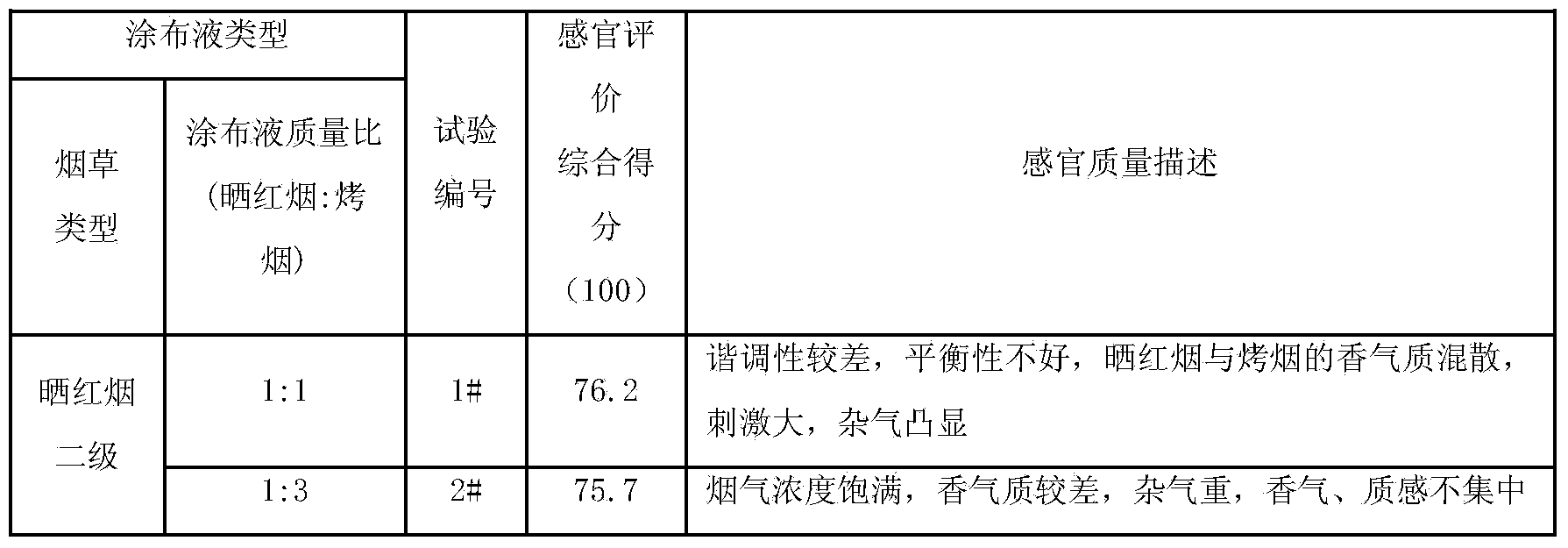

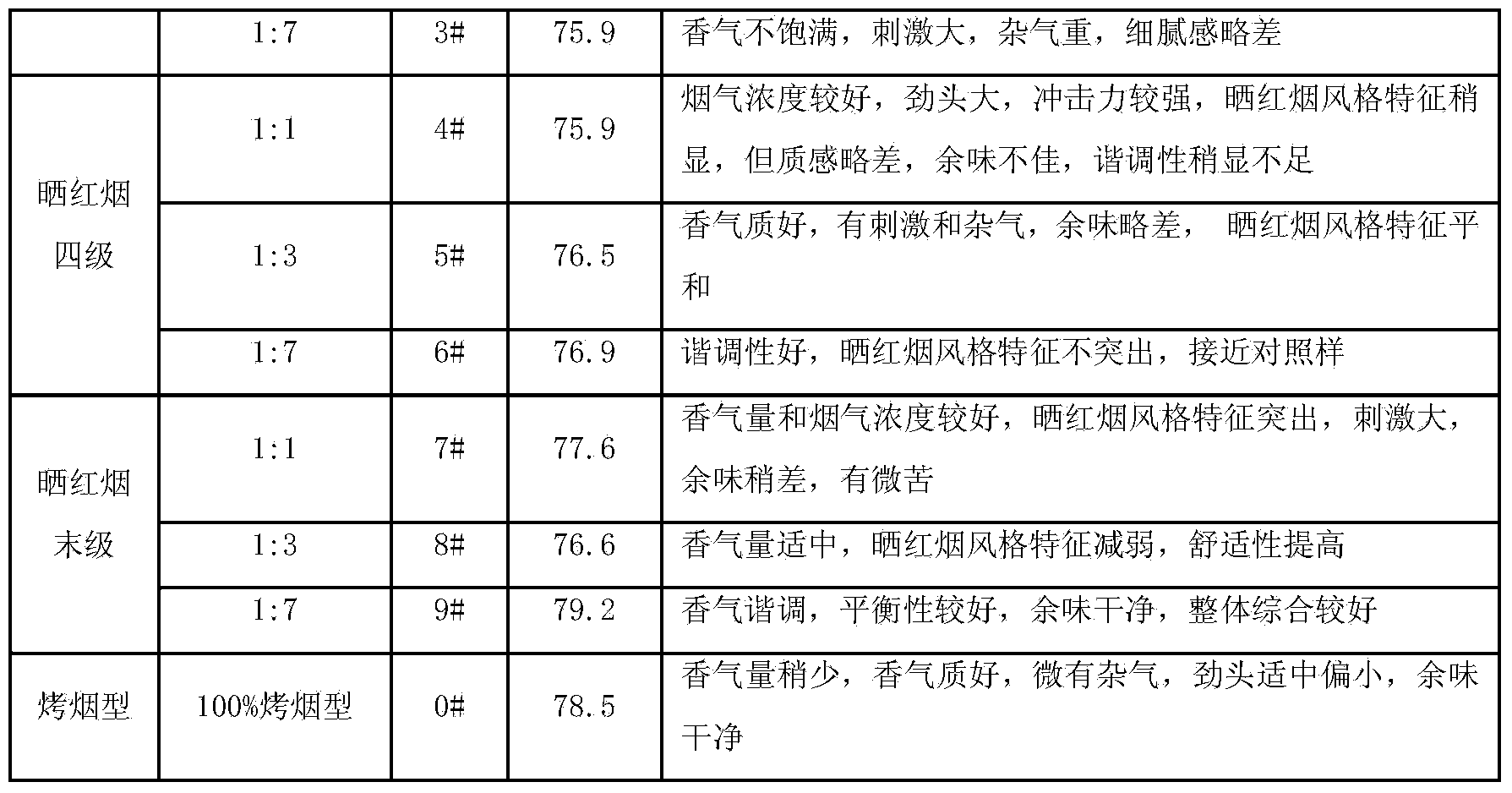

[0012] The red sun-cured tobacco used is Luzhou Baimao LY-1 grade 2, grade 4 and final grade, and the flue-cured tobacco is a grade of red large variety fragments; water is used as a solvent, and the ratio of solid to liquid is 1:7. Tobacco and flue-cured tobacco leaves were extracted, the extraction time was 40min, and the extraction temperature was 60°C. After solid-liquid separation, the flue-cured tobacco extract and the sun-cured red tobacco extract were concentrated by conventional evaporation methods, and prepared into extracts for future use as flue-cured tobacco-type film bases;

[0013] Mix flue-cured tobacco extract and sun-cured red tobacco extract respectively according to the mass ratio of 1:1, 1:3 and 1:7, then add 4% by mass glycerol as a humectant, and mix it with water to a density of 1.15g / mL of the coating solution, the flue-cured tobacco-type sheet base is coated with the coating solution, and after drying and cutting, the reconstituted tobacco leaves of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com