Process for online coating soft brazing material on surface of copper alloy high-frequency welded tube for heat exchanger

A technology for heat exchangers and high-frequency welded pipes, used in devices for coating liquids on surfaces, pretreatment surfaces, coatings, etc. The high price of brazing furnaces achieves the effect of fast speed, simple method and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

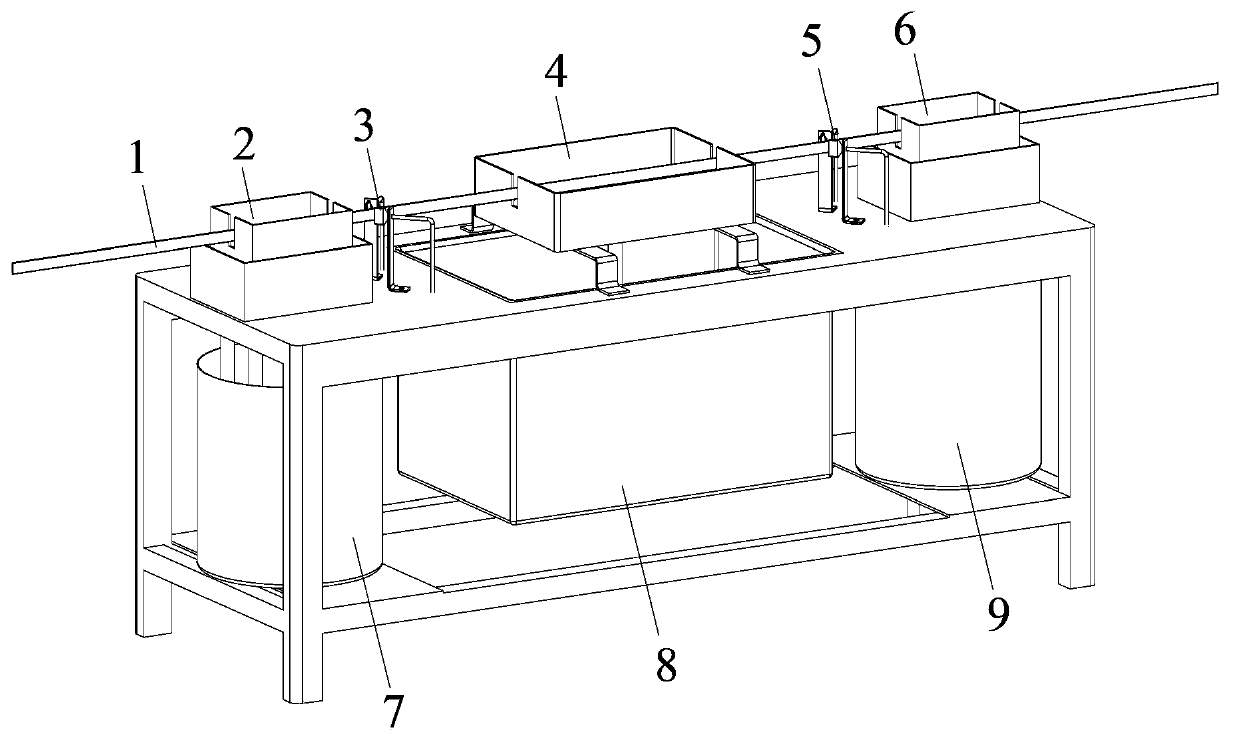

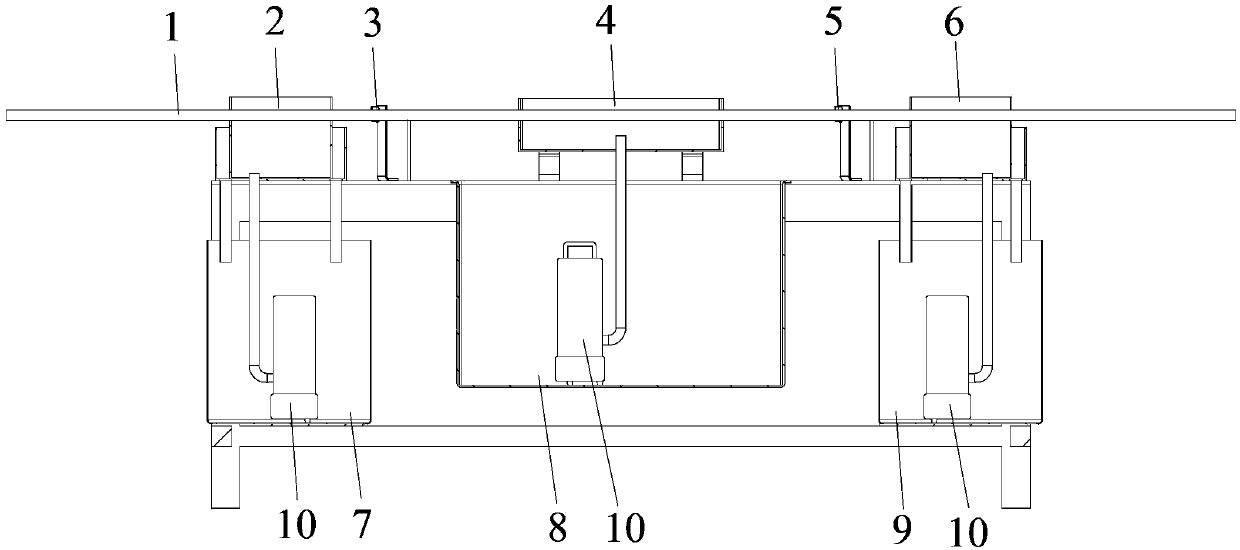

[0019] Embodiments of the present invention will now be described with reference to the drawings, in which like reference numerals represent like elements.

[0020] Please refer to Figure 1-2 , the on-line coating process of soldering material on the surface of copper alloy high-frequency welded pipes for heat exchangers comprises the following steps:

[0021] First, the advancing speed of the copper alloy high-frequency welded pipe material 1 for heat exchangers is 100 to 150 m / min.

[0022] Second, the pipe 1 is passed through the pipe surface cleaning box 2 to infiltrate and clean the surface of the pipe 1 . This step is because the pipe 1 has been exposed to many processes such as drawing and friction in the raw material processing process, high-frequency welding forming process, etc., and there are harmful effects such as oxidation and drawing oil residue on the surface that affect the solder coating. The surface of the pipe 1 must be cleaned in-line before the solderi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com