Automatic assembly device and assembly method of valve stem sealing ring

An automatic assembly device and automatic assembly technology, applied in the direction of metal processing, metal processing equipment, manufacturing tools, etc., can solve problems such as difficulty in adapting to the needs of automatic assembly market competition, unstable quality, inconvenient installation work, etc., to improve product qualification rate and assembly efficiency, reducing production costs and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

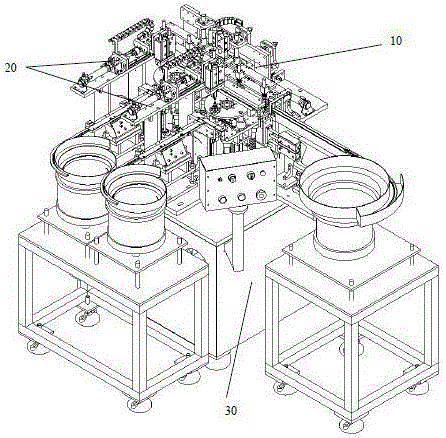

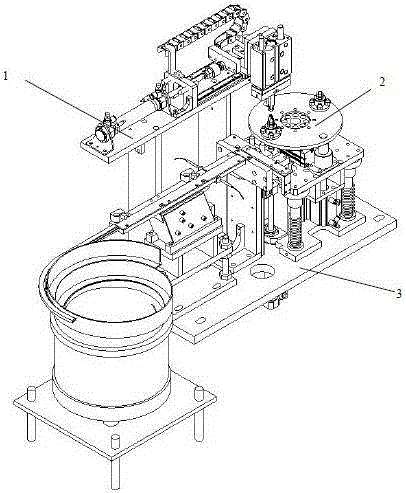

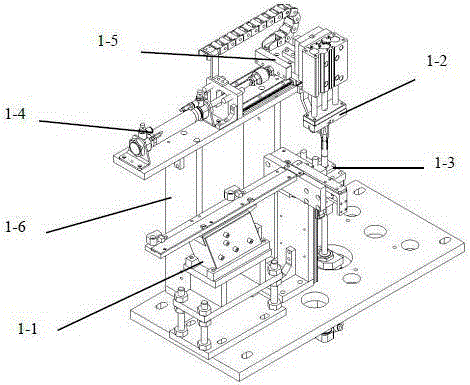

[0092] like figure 1 As shown, the automatic assembly device of the valve stem sealing ring of the present invention includes a valve stem automatic feeding device 10, two sets of sealing ring automatic assembly devices 20, a bed frame 30, the valve stem automatic feeding device 10 and the sealing ring automatic assembly The device 20 is arranged on the bed frame 30; the inside of the bed frame 30 is provided with an electromechanical control system and a pneumatic control system of the machine tool;

[0093] The valve stem automatic feeding device 10 separates the valve stems from the feeding system one by one, and moves the valve stems one by one to the position to be assembled in an orderly manner, so as to realize the automatic feeding of the valve stems; Automatic assembly of the stem sealing ring; finally, the valve stem after assembly is transferred and discharged;

[0094] Two sets of sealing ring automatic assembly devices 20 respectively complete the automatic feedi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com