Soft grinding and polishing disc

A polishing disc, soft technology, applied in the direction of grinding tools, etc., to achieve the effect of improving the yield of finished products, less deformation, and good wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

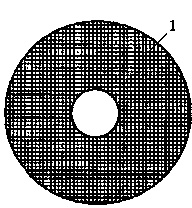

[0027] see figure 1 , shows a soft abrasive polishing disc of the present invention.

[0028] The soft abrasive polishing disc 1 has a disc structure with a through hole in the middle, which can be fixed to the grinding tool by a fixing device. The soft abrasive polishing disc 1 is used to process workpieces with high surface precision requirements such as silicon discs.

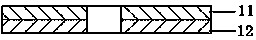

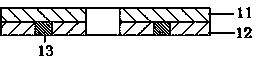

[0029] see figure 2 , shows a schematic structural view of an embodiment of the soft abrasive polishing disc of the present invention.

[0030] The soft grinding and polishing disc 1 at least includes a grinding layer 11. Through comparative analysis, the grinding layer 11 is made of a material selected from soft metals. Because soft metals are soft, when the workpiece is polished, the final polishing In the process, high-precision polishing of the surface can be achieved.

[0031] Optionally, through selection, it is found that tin, as a material in soft metals, has the advantages of good ductility and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com