Automatic handling system

An automatic and equipment technology, applied in the direction of conveyor objects, furnaces, lighting and heating equipment, etc., can solve the problems of OHT trolleys choosing the best path, creating troubles, increasing ceiling loads, and affecting transfer efficiency, etc., to improve safety and Conveying efficiency, reduced number of rails, and simple rail structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

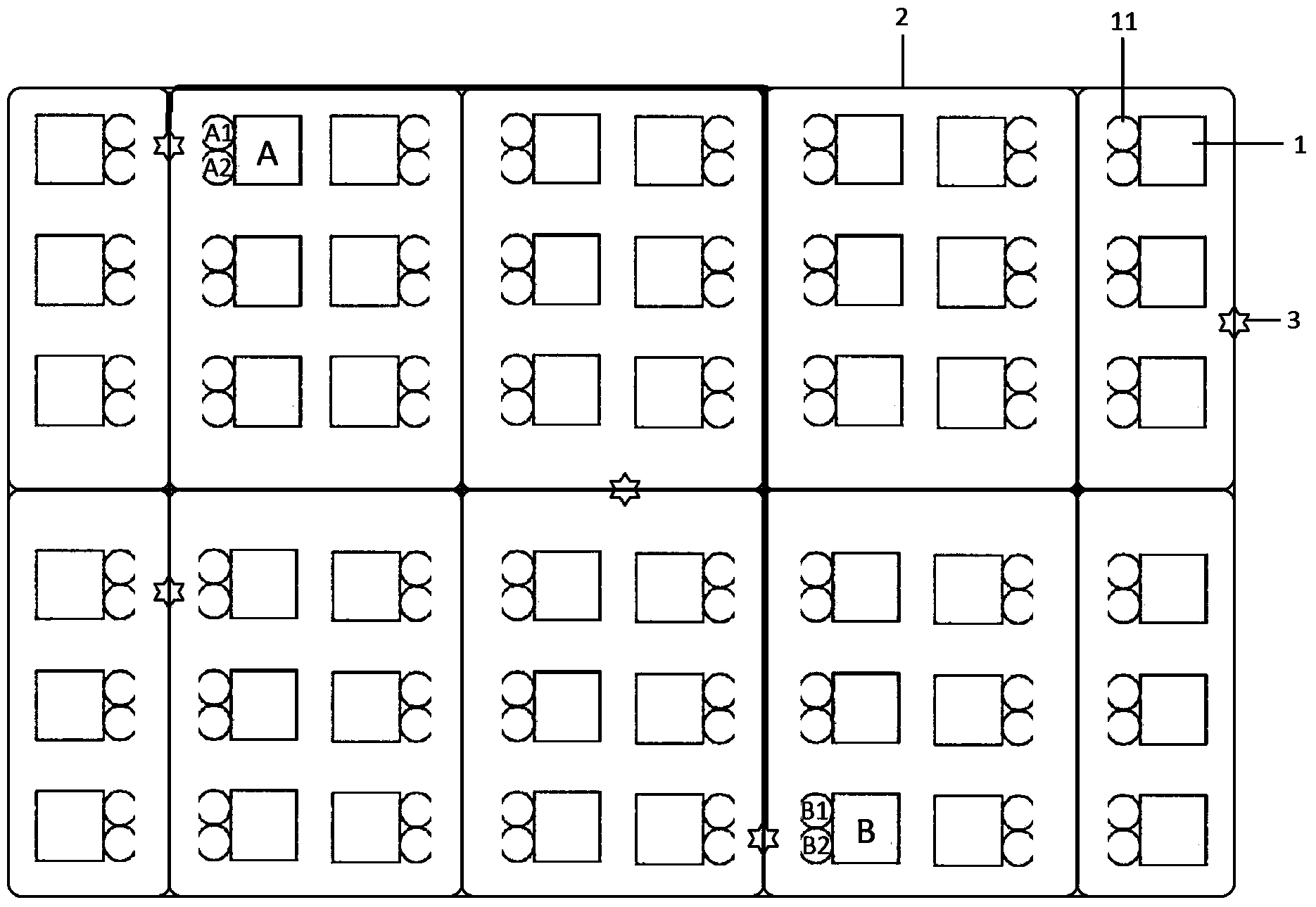

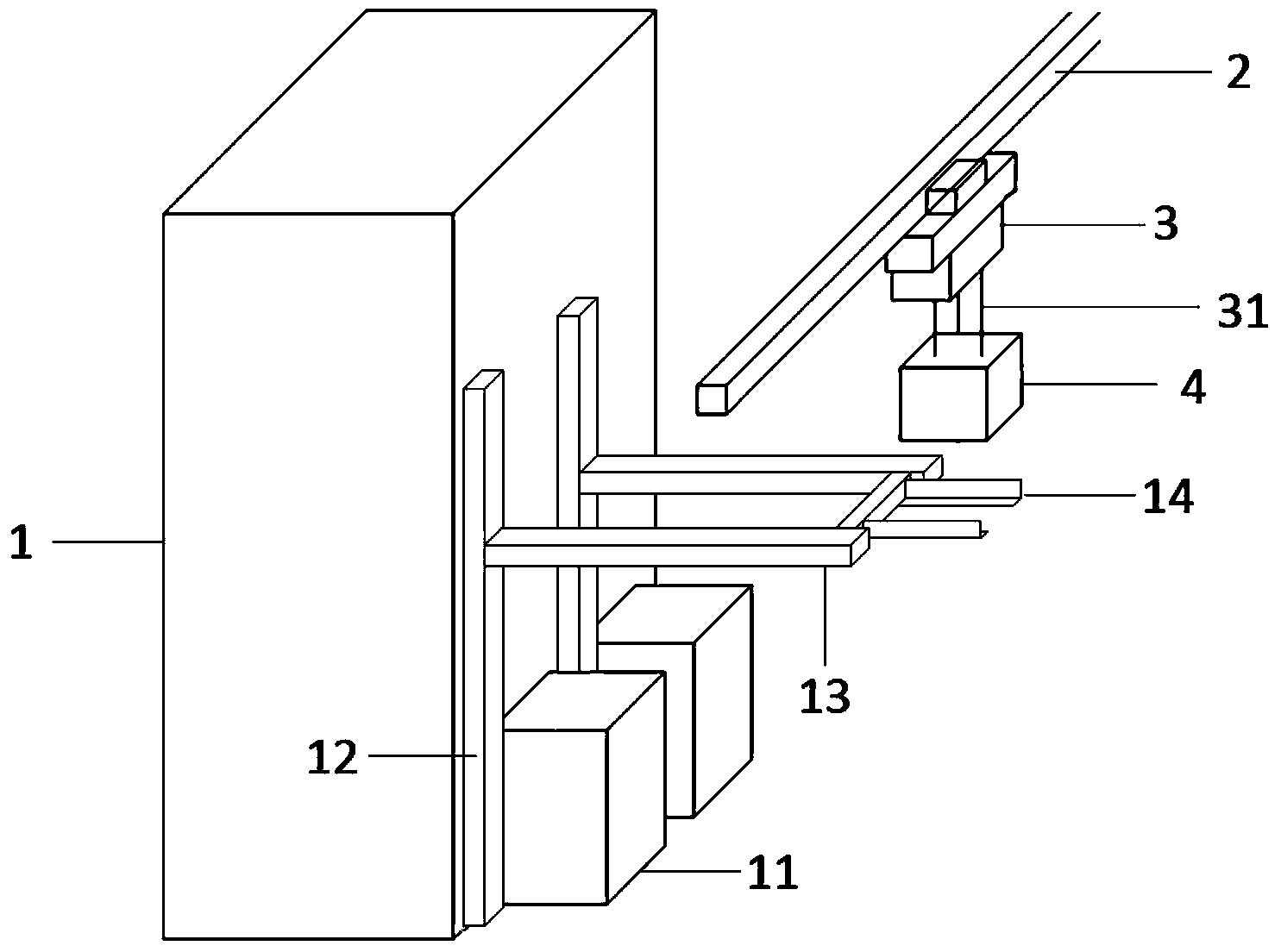

[0026] see figure 1 , the automatic conveying system of the present embodiment comprises:

[0027] 48 pieces of equipment 1 arranged in an 8×6 matrix, each equipment 1 has two stacking sections 11 for stacking wafer cassettes and an access mechanism for transporting wafer cassettes back and forth between the stacking section and the equipment aisle where the stacking section is located (not shown), in this embodiment, among the six longitudinal rows of equipment 1, the orientations of the stacking parts 11 of each row of equipment 1 are consistent, and the orientations of the stacking parts 11 of two adjacent rows of equipment 1 are opposite, thus presented figure 1 The "face-to-face" and "back-to-back" display methods of the stacking parts 11 shown can minimize the number of tracks;

[0028] The track structure is composed of a plurality of interconnected tracks 2 that are suspended and fixed on the top of the system space. Each equipment 1 stacked with 11 equipment aisles ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com