Preparation method of ZnSnO3 nano material with high gas sensitivity

A technology capable of zinc metastannate and nanomaterials, applied in nanotechnology, chemical instruments and methods, tin compounds, etc., can solve problems such as not meeting expected requirements, and achieve uniform morphology, mild reaction conditions, and low energy consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

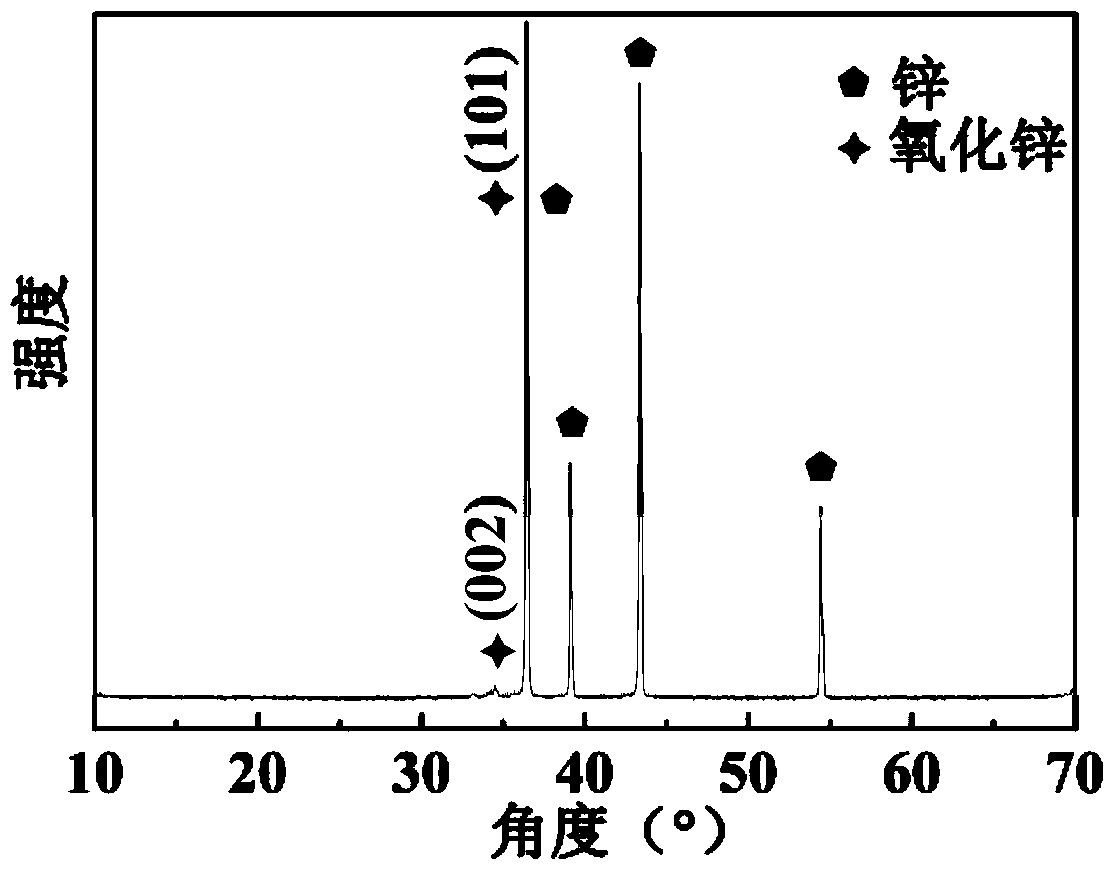

Embodiment 1

[0028] Step 1: preparing zinc oxide. 1 × 1 cubic centimeter of cleaned zinc flakes and 30 milliliters (1.5 grams per liter) of sodium dioctyl sulfosuccinate solution are put into a 50 milliliter polytetrafluoroethylene autoclave, and 100 After heating for 2 hours at 100°C, the reacted zinc flakes were taken out, and rinsed with absolute ethanol and distilled water successively;

[0029] Step 2: Put the zinc sheet obtained in the first step, 0.75 gram of urea, 0.25 gram of potassium stannate and 30 milliliters of hydroalcoholic solution (the volume of dehydrated alcohol is 38%) into 50 milliliters of polytetrafluoroethylene autoclaves ;

[0030] Step 3: Put the autoclave into an electric heating constant temperature blast drying oven and heat it at 120 degrees Celsius for 0.5 hours;

[0031] Step 4: Collect the zinc flakes and precipitates obtained from the reaction, rinse them with absolute ethanol and distilled water in turn, and dry them in an electric constant temperature...

Embodiment 2

[0033] Step 1: preparing zinc oxide. 1 × 1 cubic centimeter of cleaned zinc flakes and 30 milliliters (1.5 grams per liter) of sodium dioctyl sulfosuccinate solution are put into a 50 milliliter polytetrafluoroethylene autoclave, and 100 After heating for 2 hours at 100°C, the reacted zinc flakes were taken out, and rinsed with absolute ethanol and distilled water successively;

[0034] Step 2: Put the zinc sheet obtained in the first step, 0.75 gram of urea, 0.25 gram of potassium stannate and 30 milliliters of hydroalcoholic solution (the volume of dehydrated alcohol is 38%) into 50 milliliters of polytetrafluoroethylene autoclaves ;

[0035] Step 3: Put the autoclave into an electric constant temperature blast drying oven and heat it at 120 degrees Celsius for 3 hours;

[0036] Step 4: Collect the zinc flakes and precipitates obtained from the reaction, rinse them with absolute ethanol and distilled water in turn, and dry them in an electric constant temperature blast dry...

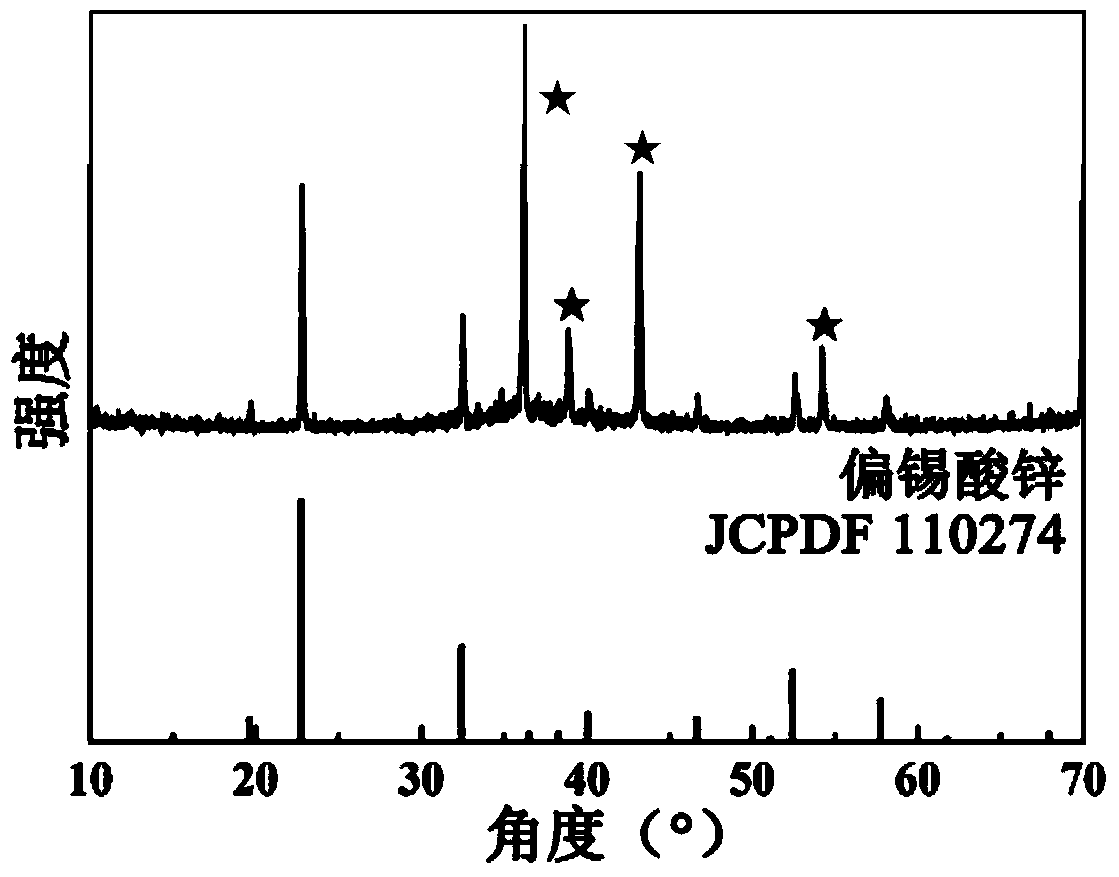

Embodiment 3

[0038] Step 1: preparing zinc oxide. 1 × 1 cubic centimeter of cleaned zinc flakes and 30 milliliters (1.5 grams per liter) of sodium dioctyl sulfosuccinate solution are put into a 50 milliliter polytetrafluoroethylene autoclave, and 100 After heating for 2 hours at 100°C, the reacted zinc flakes were taken out, and rinsed with absolute ethanol and distilled water successively;

[0039] Step 2: Put the zinc sheet obtained in the first step, 0.75 gram of urea, 0.25 gram of potassium stannate and 30 milliliters of hydroalcoholic solution (the volume of dehydrated alcohol is 38%) into 50 milliliters of polytetrafluoroethylene autoclaves ;

[0040] Step 3: Put the autoclave into an electric heating constant temperature blast drying oven and heat it at 120 degrees Celsius for 10 hours;

[0041] Step 4: Collect the zinc flakes and precipitates obtained from the reaction, rinse them with absolute ethanol and distilled water in turn, and dry them in an electric constant temperature ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com