Copper titanate nanoneedle and preparation method thereof

A nano-needle, copper titanate technology, applied in nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve the problems of copper titanate nano-needle reporting and other problems, and achieve the effect of batch preparation, low cost and low preparation temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

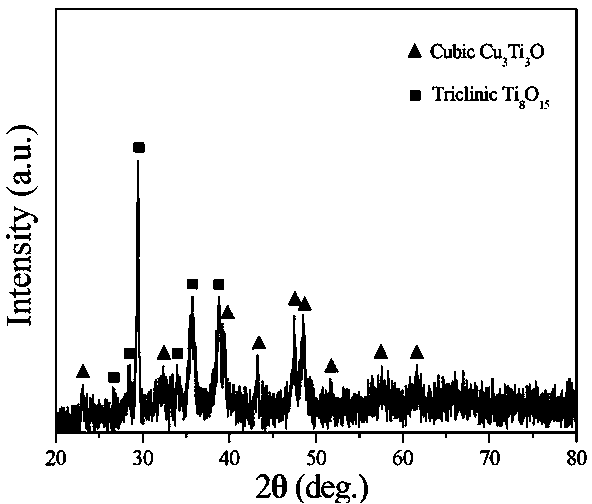

[0024] Mix tetrabutyl titanate, copper acetate, SDS and water evenly, place in a reaction vessel and seal it, the molar ratio of tetrabutyl titanate to copper acetate is 1:1, tetrabutyl titanate, copper acetate account for water 10% of the weight, the amount of SDS accounts for 5% of the water weight, and the total amount of tetrabutyl titanate, copper acetate, SDS and water accounts for 60% of the filling degree of the airtight container. Then, the temperature was kept at 200° C. for 24 hours, and finally a flocculent gray product of copper titanate nanoneedles with a length of about 6 μm and a diameter of about 50 nm at the tip of the nanoneedles was obtained.

Embodiment 2

[0026] Mix tetrabutyl titanate, copper acetate, SDS and water evenly, place in a reaction vessel and seal it, the molar ratio of tetrabutyl titanate to copper acetate is 1:1, tetrabutyl titanate, copper acetate account for water 8% by weight, the amount of SDS accounts for 5% by weight of water, and the total amount of tetrabutyl titanate, copper acetate, SDS and water accounts for 50% of the filling degree of the airtight container. Then, it was kept at a temperature of 180°C for 24 hours, and finally a flocculent gray product of copper titanate nanoneedles with a length of about 6 μm and a diameter of the nanoneedle tip of about 50 nm was obtained.

Embodiment 3

[0028] Mix tetrabutyl titanate, copper acetate, SDS and water evenly, place in a reaction vessel and seal it, the molar ratio of tetrabutyl titanate to copper acetate is 1:1, tetrabutyl titanate, copper acetate account for water 7% by weight, the amount of SDS accounts for 4% by weight of water, and the total amount of tetrabutyl titanate, copper acetate, SDS and water accounts for 60% of the filling degree of the airtight container. Then it was kept at a temperature of 180° C. for 48 hours, and finally a flocculent gray product of copper titanate nanoneedles with a length of about 6 μm and a diameter of the nanoneedle tip of about 50 nm was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com