Method for continuously preparing N, N'-bis(1,4-dimethylpentyl)-p-phenylenediamine

A technology of dimethylpentyl and p-phenylenediamine is applied in the field of energy-saving and high-efficiency preparation technology, which can solve the problems of difficulty in recycling and high cost, and achieve the effects of saving labor costs, reducing costs and reducing labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

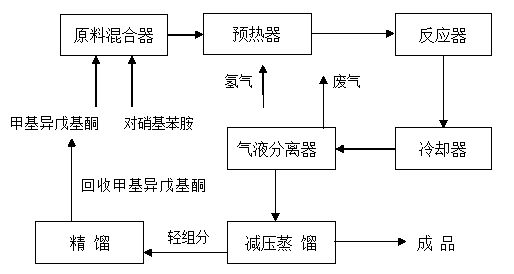

Method used

Image

Examples

Embodiment 1

[0019] Add 1382.0 grams of p-nitroaniline and 5710.4 grams of 5-methyl-2-hexanone into the raw material mixer. After mixing well, use the delivery pump to drive the mixed raw materials into the preheater at a speed of 20ml / h to keep the preheater. The temperature of the heater is 145~150°C. At the same time, hydrogen gas is passed into the reactor filled with palladium catalyst and replaced with nitrogen, and the reactor temperature is kept at 190~200°C, and the hydrogen pressure is kept at 0.7Mpa. After 24 hours, the Let off the liquid sample from the liquid separator, and after another 24 hours, collect the reaction solution, distill under 20mmHg vacuum, stop when the kettle temperature is 240°C, cool down and vent the vacuum, and obtain 178g of finished product. After testing, p-nitroaniline is not detected, N, The content of N'-bis(1,4-dimethylpentyl)-p-phenylenediamine is 96.31%.

Embodiment 2

[0021] The operating conditions are the same as in Example 1, the catalyst used is a platinum catalyst, and 189 grams of finished product are obtained. After testing, p-nitroaniline is not detected, and N,N'-bis(1,4-dimethylpentyl)-p-phenylenediamine The content is 97.06%.

Embodiment 3

[0023] Operating condition is the same as embodiment 1, and catalyzer used is the copper series catalyst that has reduced (CuO39W%, Cr 2 o 3 7W%, Al 2 o 3 ,54W%) the flow rate of the delivery pump was increased to 30ml / h, and 274g of finished product was obtained. After testing, p-nitroaniline was not detected, containing N,N'-bis(1,4-dimethylpentyl)terephthalene The amine content is 97.54%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com