Hydroxymethyl silicone rubber leveling plasticizer as well as production process thereof

A production process and technology of silicone rubber, applied in the field of leveling plasticizer, can solve the problems of thickening, high volatile content, thickening of modified silicone oil, etc., to increase surface brightness and smoothness, and improve surface leveling. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

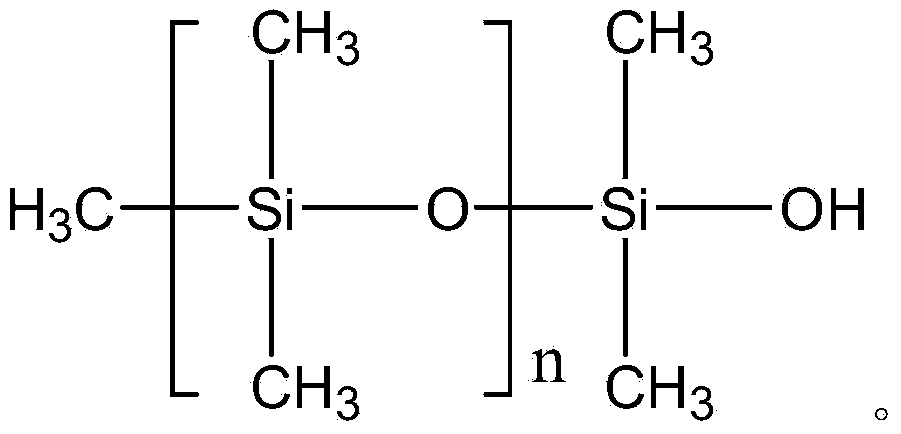

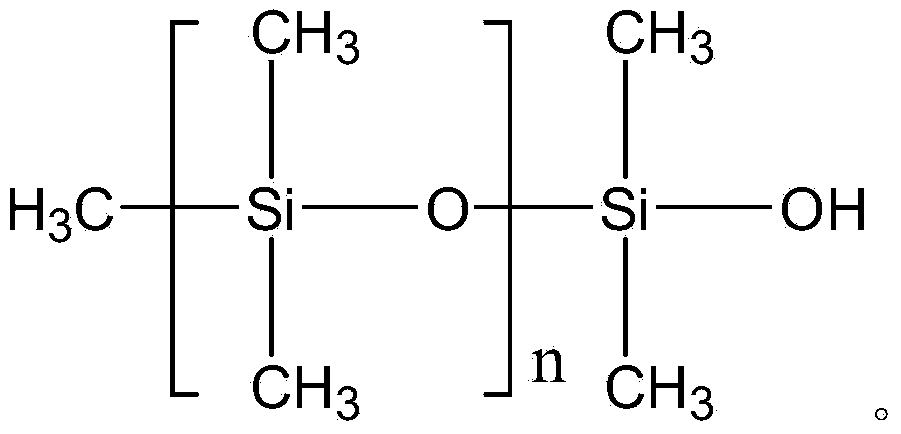

[0010] Select the main raw material as dimethylcyclosiloxane mixture (DMC) or octamethylcyclotetrasiloxane (D4) 1000g, add an appropriate amount of dimethyldisiloxane (determined according to the kinematic viscosity of the final product, If a leveling plasticizer with a kinematic viscosity of 100cs is obtained, add about 100g of dimethyldisiloxane), react with 30g of concentrated sulfuric acid at 20°C for 12h, neutralize with 48g of sodium bicarbonate, add 1000g of water to wash twice, add Tetramethylammonium hydroxide 2g, be warming up to 135 degrees centigrade, react 8h, heat up 180 degrees again, process low boiler with thin-film evaporator, cool down, finally obtain the molecular formula that yield is about 70% as

[0011] Hydroxymethyl silicone rubber leveling plasticizer, and 30% of dimethyl silicone oil and hydroxyl silicone oil.

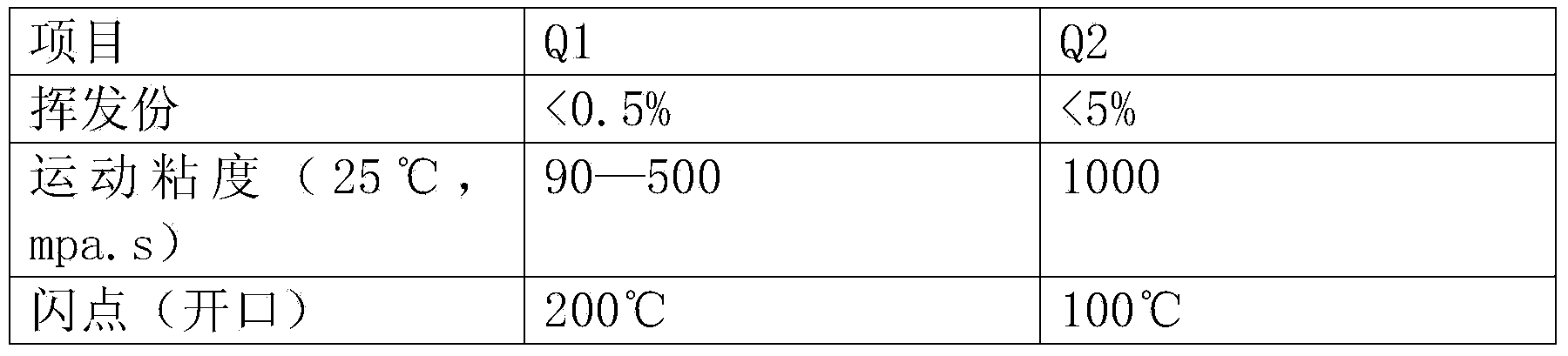

[0012] Hydroxymethyl silicone rubber leveling plasticizer is a colorless and odorless transparent liquid, soluble in organic solvents and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com