Epoxy resin-modified silicone rubber composite and applications thereof

A silicone rubber composition and epoxy resin technology, applied in the direction of epoxy resin glue, adhesive, adhesive type, etc., can solve the problems of different adhesive properties, different formulations and components, and different use occasions, etc. Good bonding performance, easy to repair, high strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

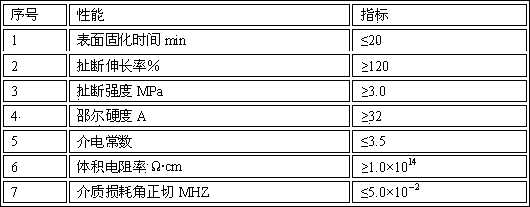

Image

Examples

Embodiment 1

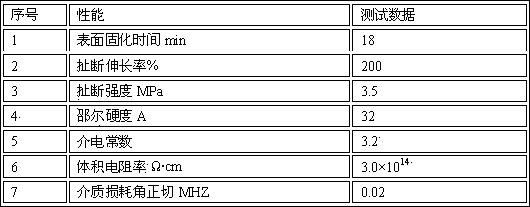

[0020] The following raw materials in parts by mass: 80 parts of room temperature vulcanized silicone rubber, 21 parts of EP01441-310 epoxy resin, 0.9 parts of KH-550 coupling agent, 1.3 parts of triethylenetetramine and 2 parts of 501 Reflux liquid; mixing by stirring to prepare an epoxy resin-modified silica gel composition.

[0021] The performance indicators of the epoxy resin-modified silica gel composition of Example 1 are shown in Table 2.

[0022] Table 2: Performance test data of the silica gel composition modified by epoxy resin in Example 1

[0023]

[0024] Comparing Table 1 and Table 2, it can be seen that the performances of Example 1 all meet the index requirements.

Embodiment 2

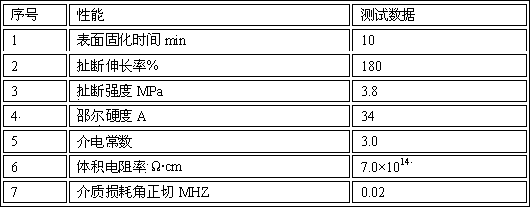

[0026] The following raw materials in parts by mass: 80 parts of room temperature vulcanized silicone rubber, 20 parts of EP01441-310 epoxy resin, 1 part of KH-550 coupling agent, 1.5 parts of triethylenetetramine and 3 parts of 501 Reflux liquid; mixing by stirring to prepare an epoxy resin-modified silica gel composition.

[0027] Table 3 shows the performance indexes of the epoxy resin-modified silica gel composition of Example 2.

[0028] Table 3: Performance test data of the silica gel composition modified by epoxy resin in Example 2

[0029]

[0030] Comparing Table 1 and Table 3, the performances of Example 2 all meet the index requirements.

Embodiment 3

[0032] The following raw materials in parts by mass: 80 parts by mass of room temperature vulcanized silicone rubber, 19 parts by mass of EP01441-310 epoxy resin, 1.1 parts by mass of KH-550 coupling agent, 1.7 parts by mass of triethylenetetramine and 4 parts by mass of 501 reflux solution; by stirring and mixing, an epoxy resin-modified silica gel composition was obtained.

[0033] The performance indicators of the epoxy resin-modified silica gel composition of Example 3 are shown in Table 4.

[0034] Table 4: Performance test data of the silica gel composition modified by epoxy resin in Example 3

[0035]

[0036] Comparing Table 1 and Table 4, the performances of Example 3 all meet the index requirements.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com