Heat-resistant vinyl ester unsaturated resin and preparation method thereof

A vinyl ester and unsaturated technology, applied in the field of heat-resistant vinyl ester unsaturated resin and its preparation, can solve the problems of difficulty in meeting high temperature corrosion resistance, limited heat resistance and the like, and achieves high temperature corrosion resistance and fast curing speed. , good corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

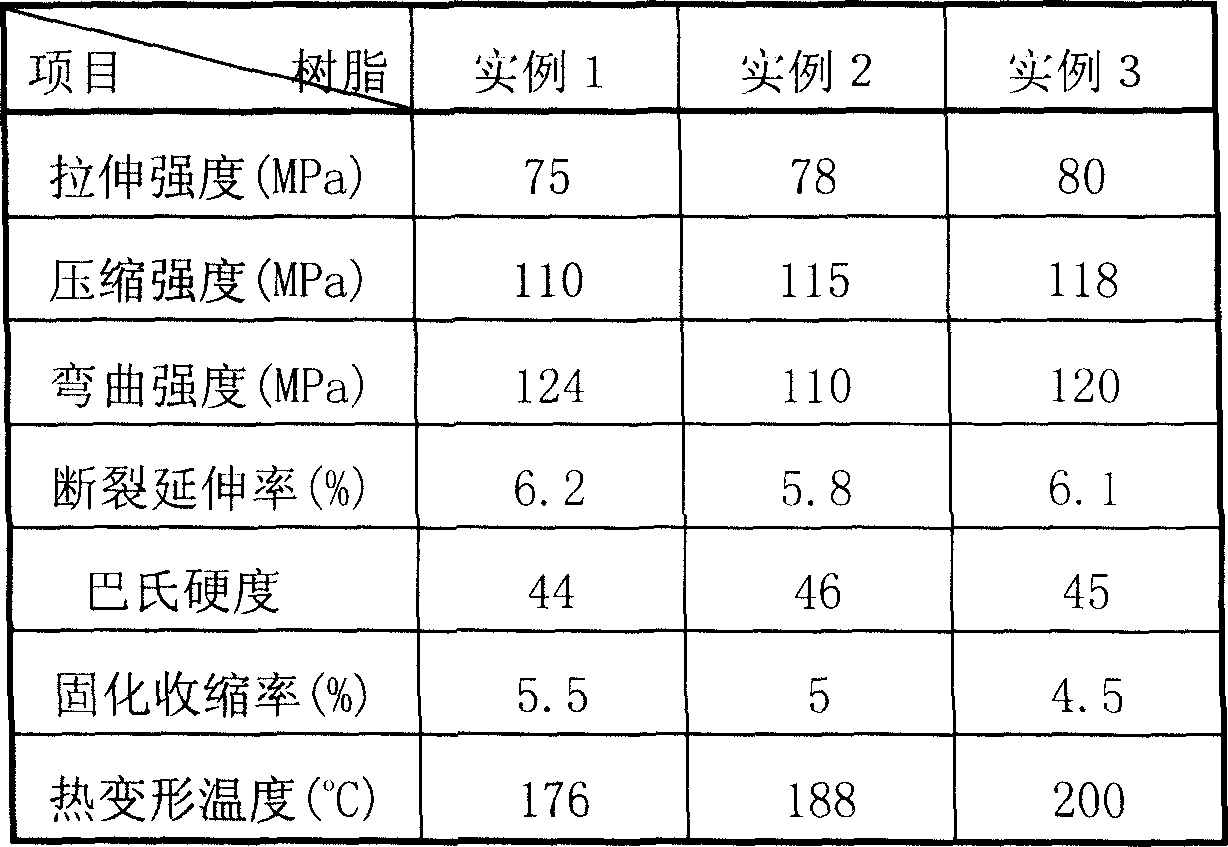

Examples

Embodiment 1

[0033] (1) Take by weight: 50 parts of bisphenol F type epoxy resin (F-51 epoxy value is 0.51), 15 parts of methacrylic acid, 5 parts of isocyanate, 10 parts of triallyl cyanurate, 19.4 parts of styrene, 0.5 parts of benzyldimethylamine catalyst, 0.05 parts of hydroquinone, and 0.05 parts of paraffin.

[0034] (2) Take 50 parts of bisphenol F-type epoxy resin and place it in a reaction kettle, heat and stir, raise the temperature to 80°C, add 15 parts of methacrylic acid, 0.5 parts of benzyldimethylamine catalyst, and 0.05 parts of hydroquinone (add 1 / 5 of its amount first), and finish adding within 2 hours. Then heat up to 100°C, stir, vacuumize, the vacuum degree is -0.09~-0.1MPa, and react until the acid value is 10±2mgKOH / g (measured every 20 minutes);

[0035] (3) Cool down to 60°C, add 5 parts of isocyanate dropwise to the material, drop it in half an hour, control the temperature not to exceed 80°C, and react for 0.5h to obtain a modified vinyl ester resin;

[0036] (...

Embodiment 2

[0038](1) Take by weight: 50 parts of bisphenol F type epoxy resin (F-51 epoxy value is 0.51), 15 parts of methacrylic acid, 5 parts of isocyanate, 15 parts of triallyl cyanurate, Styrene 14.4 parts, X 2 0.5 part of titanate ionic catalyst, 0.05 part of hydroquinone, and 0.05 part of paraffin.

[0039] (2) Take 50 parts of bisphenol F-type epoxy resin and place it in a reaction kettle, heat and stir, raise the temperature to 80°C, add 15 parts of methacrylic acid, 0.5 parts of X 2 Titanate ionic catalyst, 0.05 part of hydroquinone (add 1 / 5 of its amount first), and finish adding within 2 hours. Then heat up to 100°C, stir, vacuumize, the vacuum degree is -0.09~-0.1MPa, and react until the acid value is 10±2mgKOH / g (measured every 20 minutes);

[0040] (3) Cool down to 60°C, add 5 parts of isocyanate dropwise to the material, drop it in half an hour, control the temperature not to exceed 80°C, and react for 0.5h to obtain a modified vinyl ester resin;

[0041] (4) In the dil...

Embodiment 3

[0043] (1) Take by weight: 50 parts of bisphenol F type epoxy resin (F-51 epoxy value is 0.51), 15 parts of methacrylic acid, 5 parts of isocyanate, 25 parts of triallyl cyanurate, 2.4 parts of styrene, X 3 0.5 part of titanate ionic catalyst, 0.05 part of hydroquinone, and 0.05 part of paraffin.

[0044] (2) Take 50 parts of bisphenol F-type epoxy resin and place it in a reaction kettle, heat and stir, raise the temperature to 80°C, add 15 parts of methacrylic acid, 0.5 parts of X 3 Titanate ionic catalyst, 0.05 parts of hydroquinone (1 / 5 of the amount added first), and the addition is completed within 2 hours. Then heat up to 100°C, stir, vacuumize, the vacuum degree is -0.09~-0.1MPa, and react until the acid value is 10±2mgKOH / g (measured every 20 minutes);

[0045] (3) Cool down to 60°C, add 5 parts of isocyanate dropwise to the material, drop it in half an hour, control the temperature not to exceed 80°C, and react for 0.5h to obtain a modified vinyl ester resin;

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat deflection temperature | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com