Primary and secondary module unit combination structure of high-rise module building space and connection method thereof

A technology for building space and modular units, applied in building components, building structures, buildings, etc., can solve the problems of high seismic performance requirements, non-compliance, poor technical reliability, etc., and achieve fast construction and installation speed, high seismic performance, and construction. handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below in combination with specific embodiments.

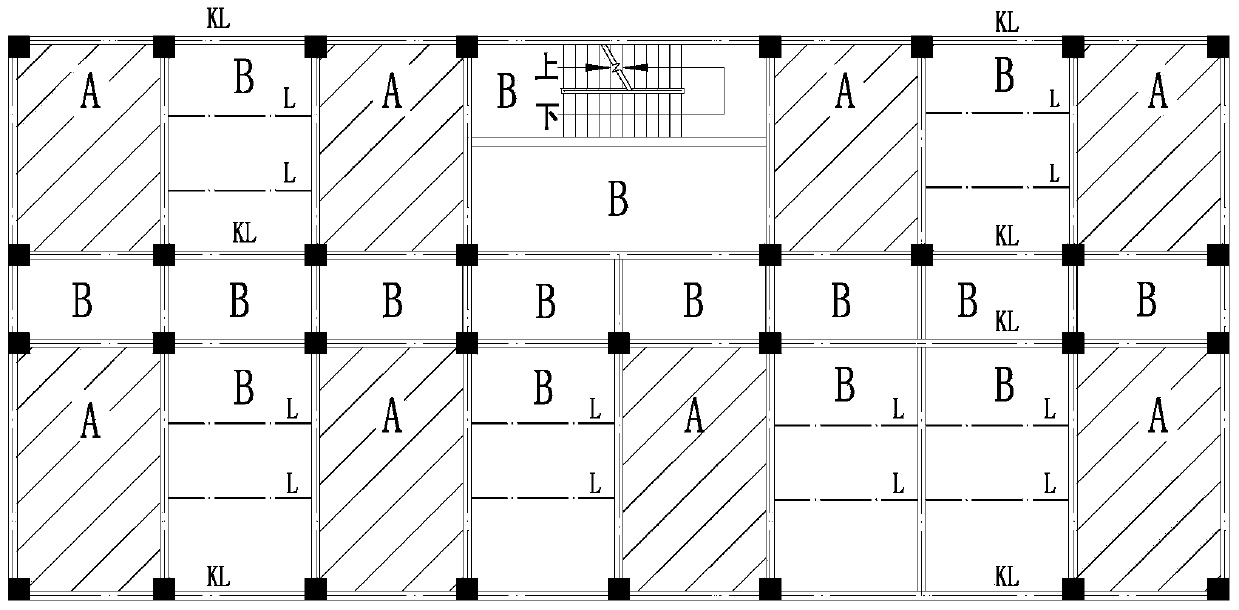

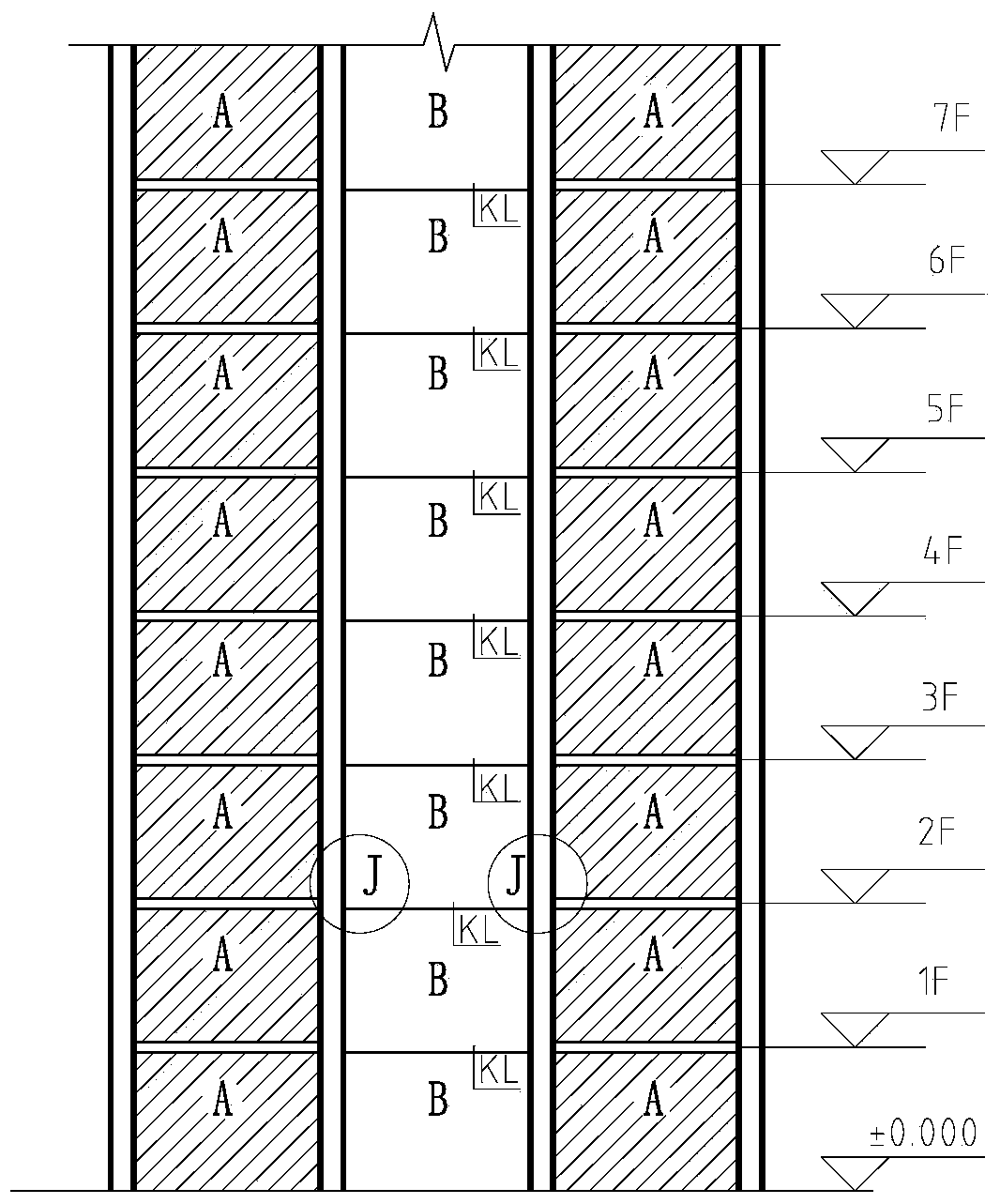

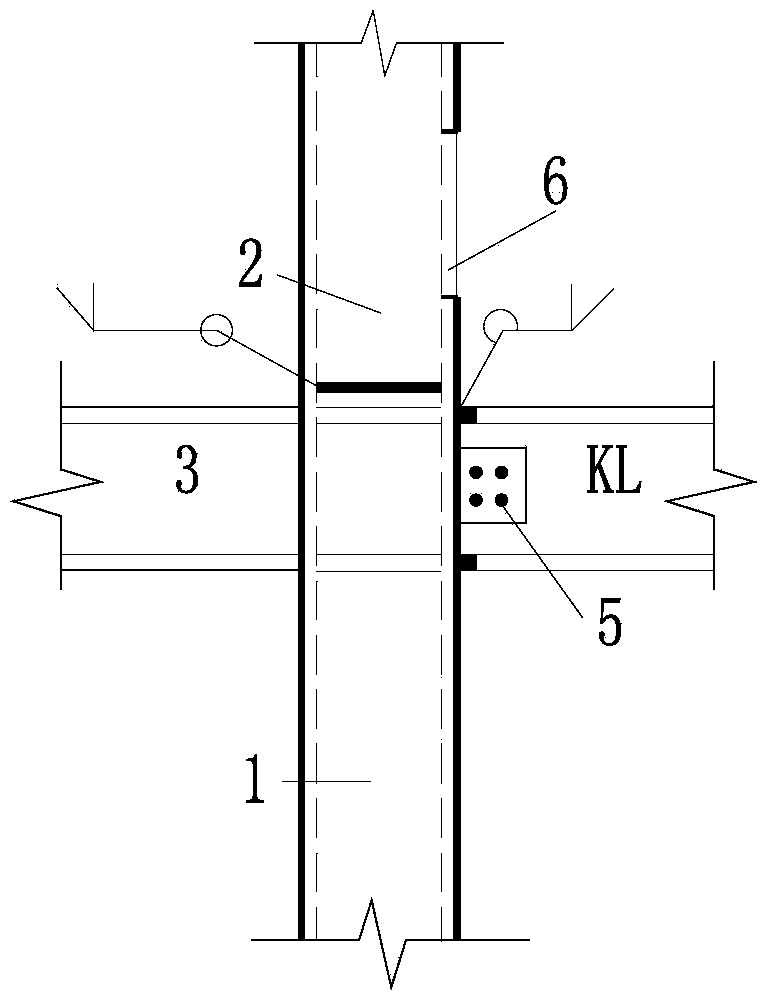

[0034] In the present invention, the modular building module unit is divided into two parts, one part is the main module unit A, and the other part is the sub-module unit B, and the two are scientifically combined in plane and space to form an overall combined structure system. Among them, the main module unit A is the main load-bearing structure, bearing the weight of itself and the sub-module unit B, and the anti-lateral force support structure is set in the main module unit A, which can effectively resist wind and earthquake. The secondary modular unit B bears only its own weight and transmits vertical and horizontal forces to the main modular unit through the relevant connections.

[0035] The combined structure of primary and secondary module units in a high-rise modular building space of the present invention includes a plurality of main module units A, on e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com