A kind of uncompensated pipeline assembly and its manufacturing method

A technology for pipeline components and manufacturing methods, applied in the direction of pipes/pipe joints/fittings, pipes, rigid pipes, etc., can solve the problems of reducing pipeline circulation efficiency, poor fluid circulation, increasing fluid resistance, etc., and achieve the effect of simplifying the construction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

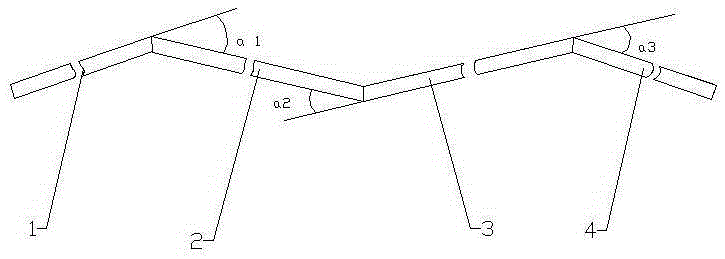

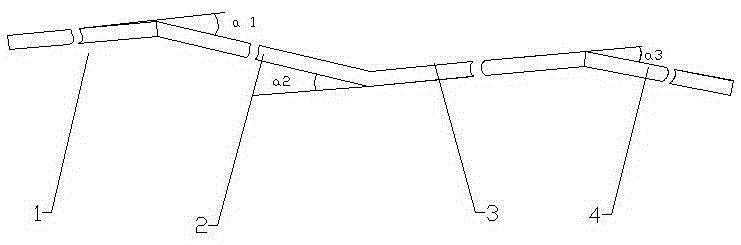

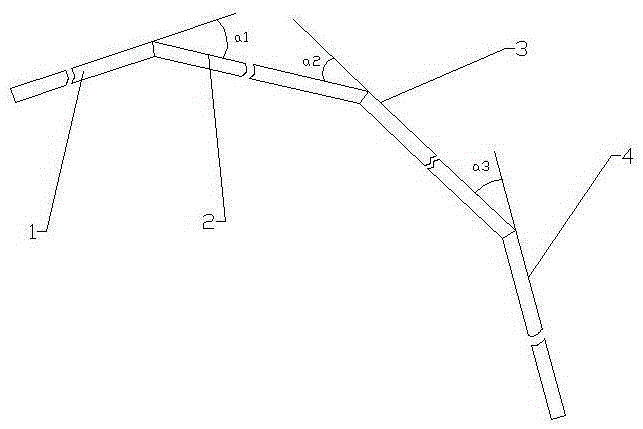

[0033] Embodiment, a non-compensated pipeline assembly, including a first pipeline 1, a second pipeline 2, a third pipeline 3 and a fourth pipeline 4; the first pipeline 1, the second pipeline 2, the third pipeline 3 and the fourth pipeline 4 Welding end to end in sequence, the first pipe 1 and the second pipe 2 form an included angle a1, the second pipe 2 and the third pipe 3 form an included angle a2, the third pipe 3 and the fourth pipe 4 form an included angle a3; the first pipe 1. The axes of the second pipeline 2 , the third pipeline 3 and the fourth pipeline 4 are not on the same straight line.

[0034] In the embodiment of the present invention, the included angle a1, included angle a2, and included angle a3 are less than 22.5 degrees, and the lengths of the first pipeline 1, the second pipeline 2, the third pipeline 3 and the fourth pipeline 4 are less than 15 meters.

[0035] In the manufacturing method of the above-mentioned non-compensated pipeline assembly, the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com