Cutting type diaphragm gas meter

A membrane gas meter and gas meter technology are applied in liquid/fluid solid measurement, contraction/expansion chamber, measurement capacity, etc., and can solve the problems of inability to safely cut off gas supply and inability of gas meter to accurately collect abnormal state information, etc. Achieve the effect of being suitable for industrial production, protecting life and property safety, and being easy to popularize

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

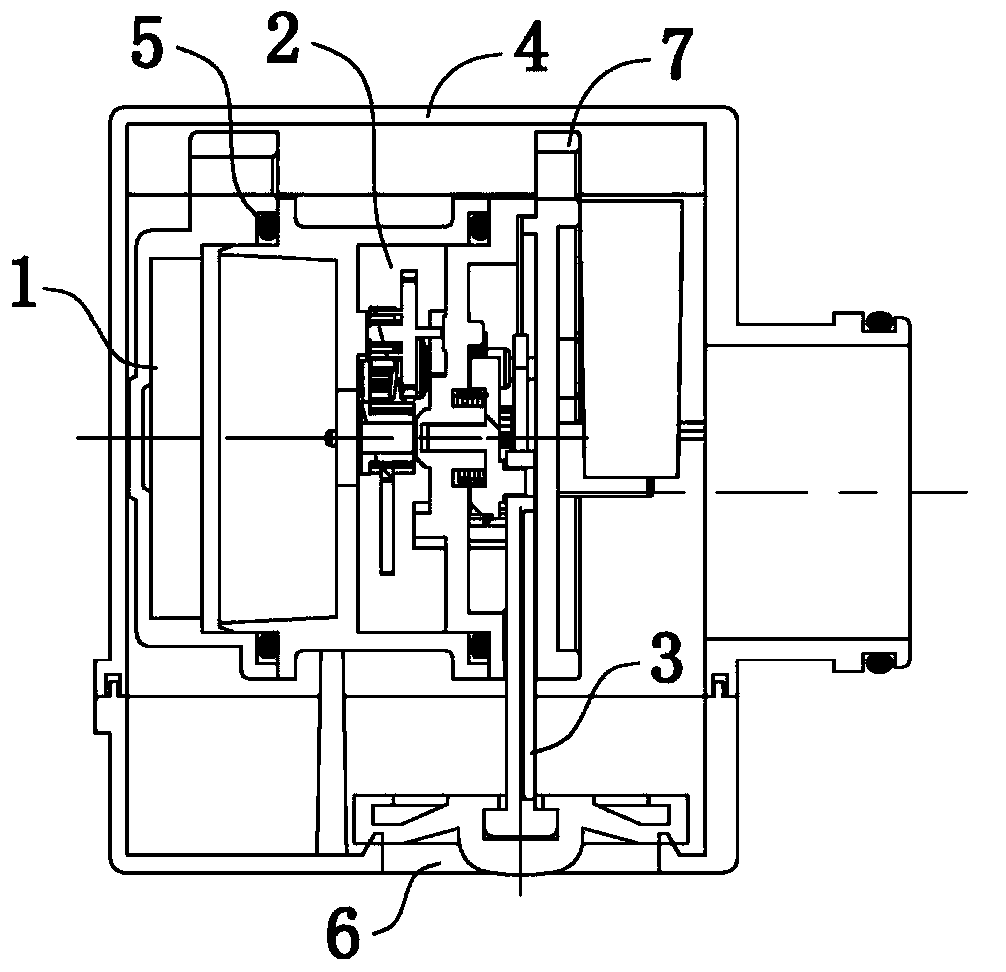

[0036] The present invention will be further elaborated below in conjunction with the accompanying drawings.

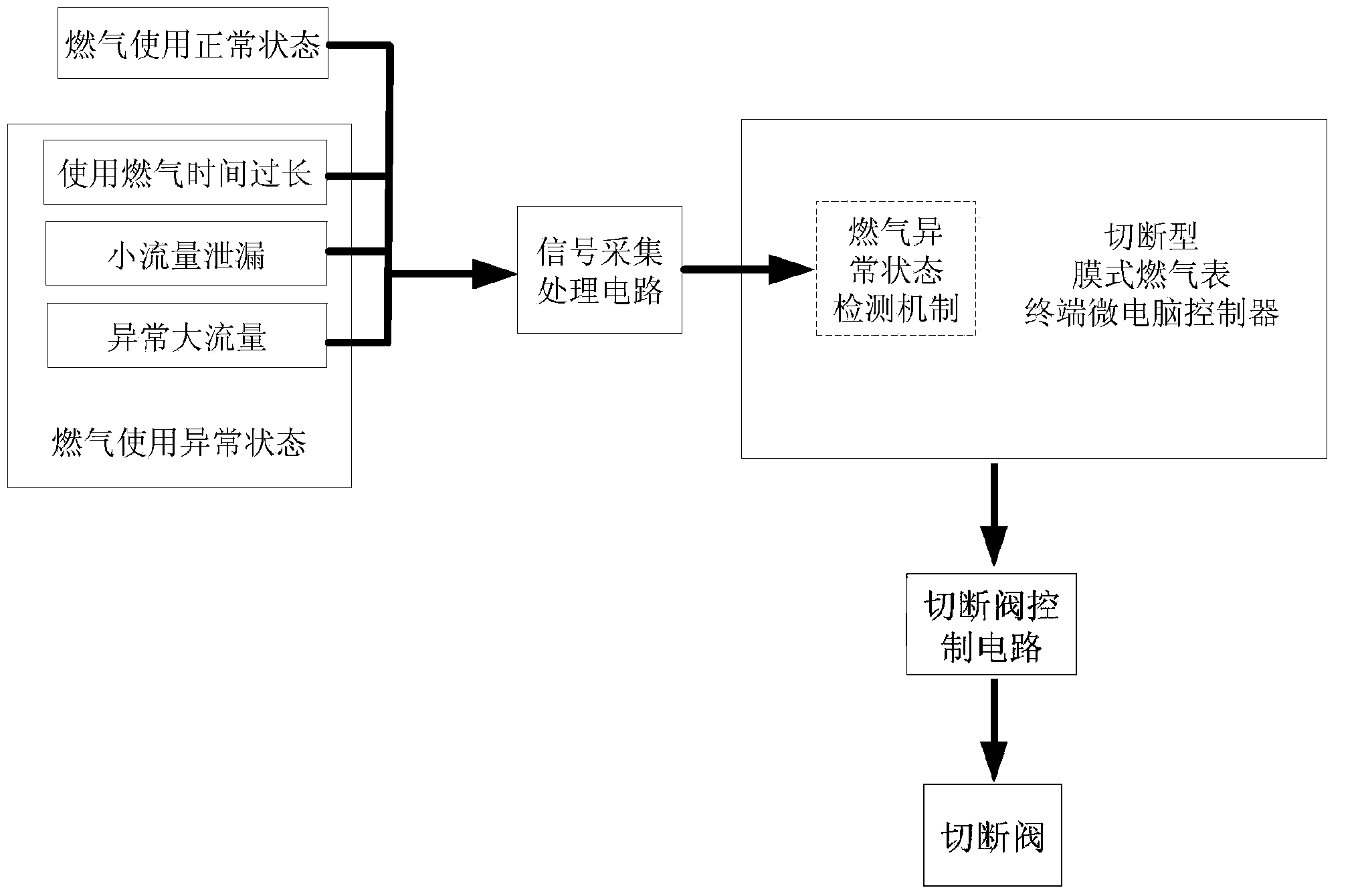

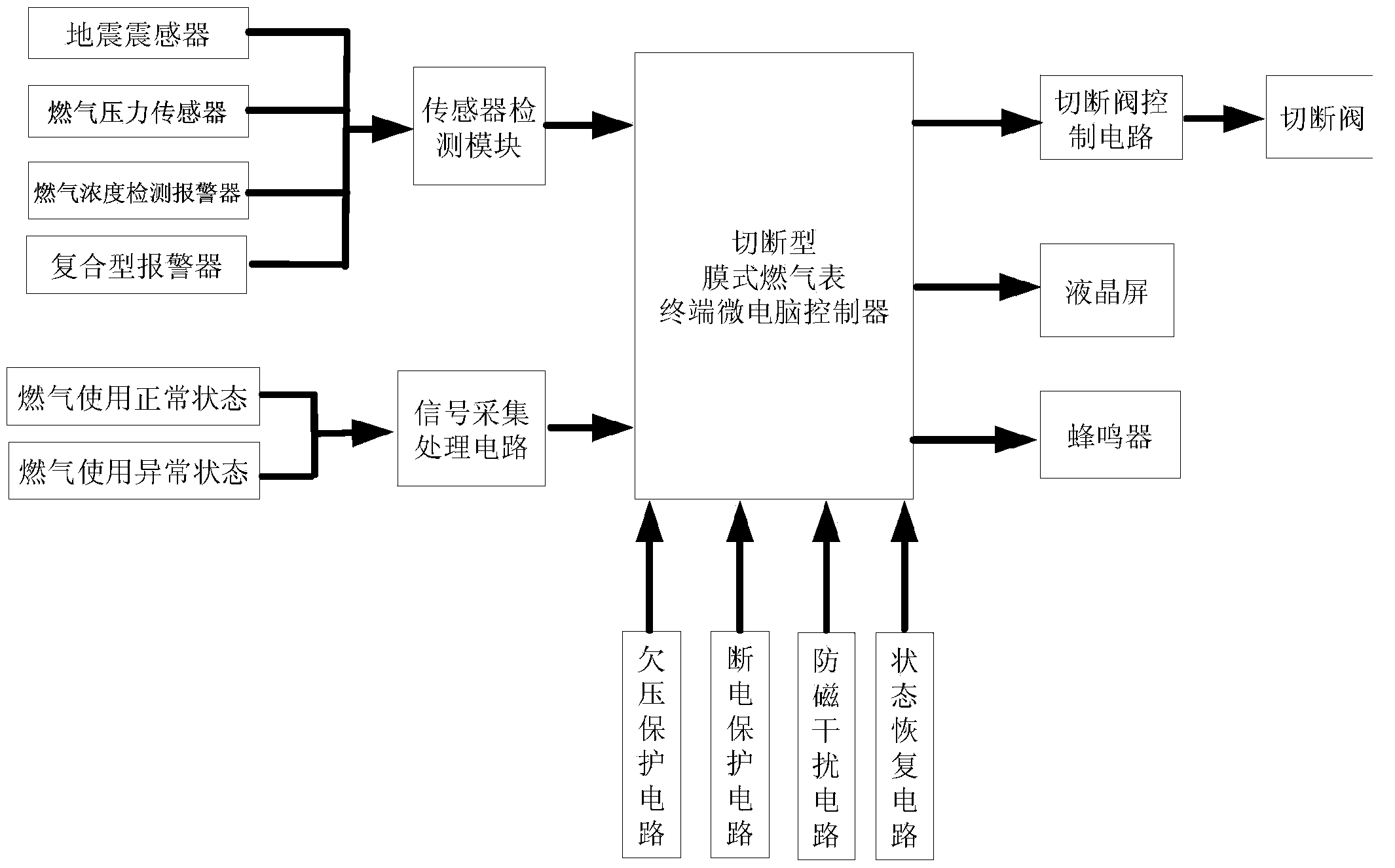

[0037] refer to figure 1 As shown, one embodiment of the present invention is a cut-off membrane gas meter, which includes a base meter body, the base meter body is provided with a gas inlet and a gas outlet, and a shut-off valve is installed on the gas inlet. The gas meter also includes a signal acquisition and processing circuit and a cut-off membrane gas meter terminal microcomputer controller. The signal acquisition and processing circuit is connected to the cut-off membrane gas meter terminal microcomputer controller. The acquisition end of the signal acquisition and processing circuit is placed At any position of the gas channel inside the base meter body, the shut-off valve is connected to the microcomputer controller of the shut-off membrane gas meter terminal through the shut-off valve control circuit;

[0038] The function of the above-mentioned gas meter s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com