Sensor structure for deepwater oceanographic engineering structural stress long-term measurement

A marine engineering and structural stress technology, applied in the field of sensors, can solve the problems of easy aging of the base of the resistance strain gauge, degumming insulation, increased capacitance, etc., to meet the accuracy and installation requirements, good isolation and sealing ability, and improve service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific embodiment of the invention will be described below in conjunction with the accompanying drawings.

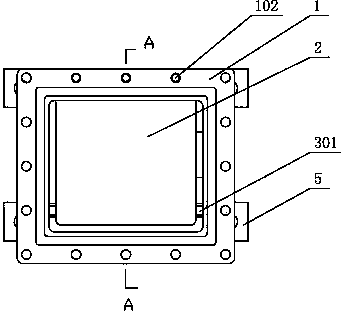

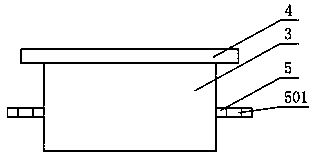

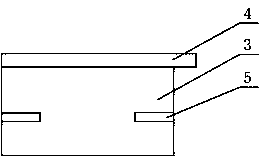

[0024] Such as figure 1 , Figure 4 As shown, the invention includes a thin-walled body 3, and a plurality of skirts 1 are also arranged on the top of the thin-walled body 3, and each skirt 1 is connected to form a rectangular frame, at least one skirt 1 is located on the inside of the side wall of the thin-walled body 3, and the remaining The three skirts 1 are all located outside the side wall of the thin-walled body 3 . Such as figure 1 , Figure 6 As shown, a cover plate 1 is installed on the top of the thin-walled body 3. The cover plate 1 is rectangular, and the middle part 1 of the cover plate is provided with a rectangular opening 101. There are 16 third installation holes 102 in the wall body 3 in the invention. Such as Figure 4 As shown, there is a chute 301 inside the thin-walled body 3, and a temperature compensation plate 302 is installed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com