Method for measuring residual thickness of metal pipeline or metal pressure container after local corrosion

A technology for pressure vessels and metal pipes, which is applied in the field of measurement and can solve problems such as large errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] The present invention will be described in detail below with an example.

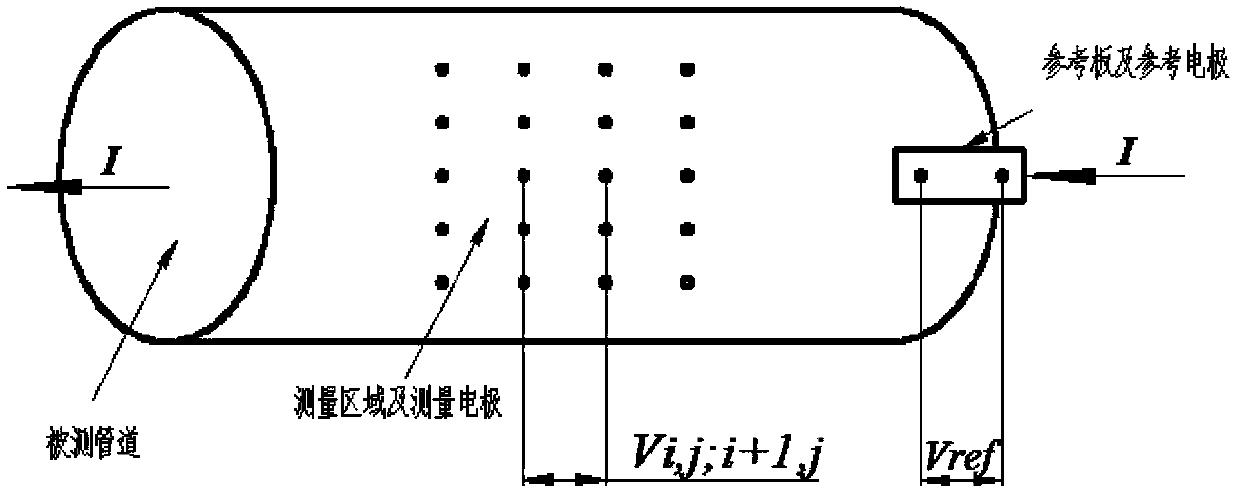

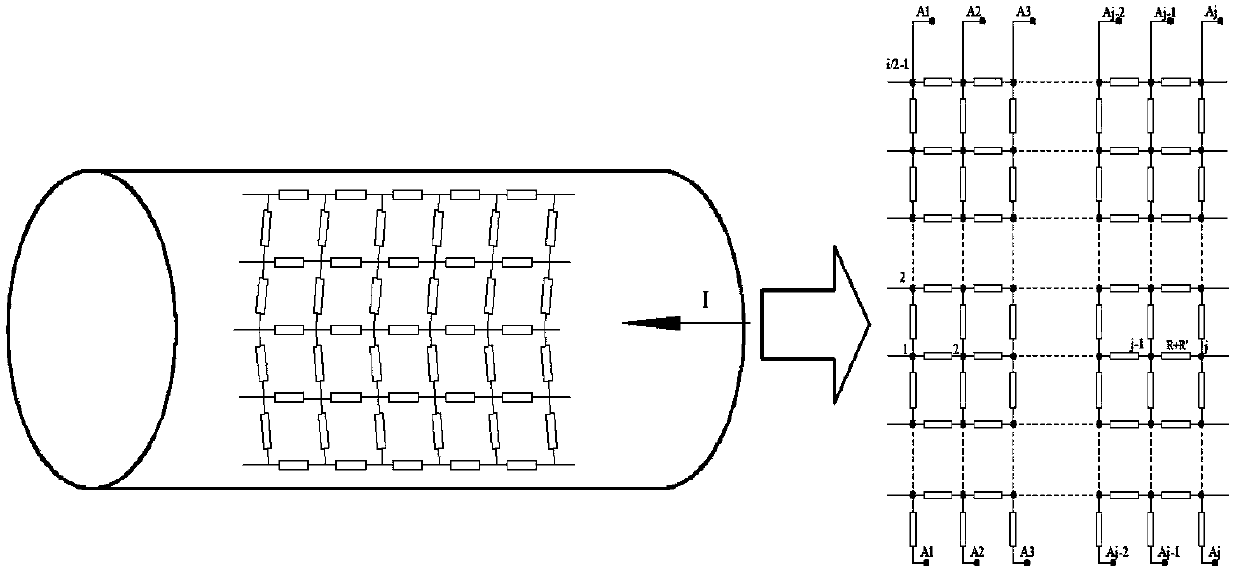

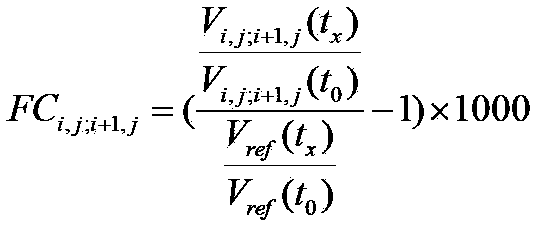

[0063] see figure 1 , in this example, the pipe thickness is 10mm, the inner diameter is 304mm low carbon steel straight pipe, based on the principle of field fingerprint method, the measurement electrode probe matrix is set on the outer wall of the metal pipe, the reference electrode pair is set on the reference plate, and the measurement electrode probe In the matrix, the probes in the circumferential direction of the pipeline are i=16 rows, and the probes in the axial direction are j=7 columns. Any two adjacent probes in the axial direction constitute a probe pair, which is used as a measuring electrode. Follow the steps below Measuring remaining thickness of localized corrosion in pipes:

[0064] (1) Input a constant current of 8A to the pipeline through the reference board. The current can be DC or AC with a frequency not greater than 20Hz. The distance between the current injection and o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com