High-frequency electrodeless lamp based on micro-channel heat pipe

A technology of microchannel heat pipe and electrodeless lamp, which is applied in the direction of discharge lamps, parts of gas discharge lamps, electrical components, etc., can solve the problems of low reliability and large calorific value, improve heat dissipation efficiency, ensure stability and reliability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

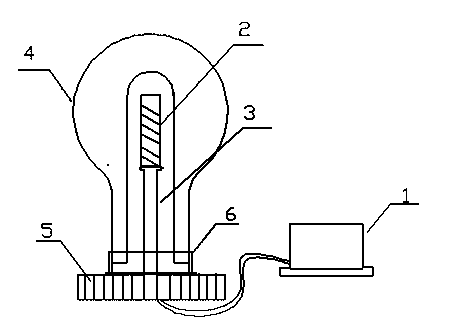

[0021] see figure 1 , a high-frequency electrodeless lamp design based on microchannel heat pipes. It includes a high-frequency generator 1, an electromagnetic coupler 2, a heat pipe 3, a foam body 4, and cooling fins 5. The electromagnetic coupler 2 is nested on the upper end of the heat pipe 3 and placed in the concave cavity of the bubble body 4. The lower end of the heat pipe is sealed and bonded to the heat dissipation fin 5. The holes are fixed on the fins 5 .

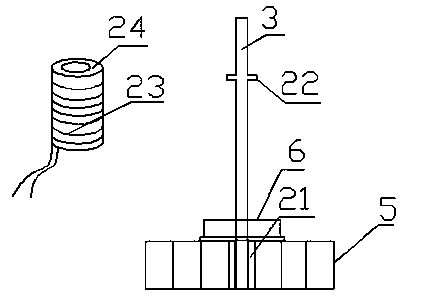

[0022] see figure 2 The magnetic core of the electromagnetic coupler 2 is a magnetic tube 24 made of high-frequency ferrite material, the induction coil 23 is directly wound on the magnetic core 24 , and the lead wire is electrically connected to the high-frequency generator 1 . A circle of copper gasket 22 is welded in the upper part of the heat pipe to support the coupler 2, and the electromagnetic coupler magnetic core 24 is nested and in close contact with the upper end of the heat pipe 3, which is benefi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com